Locally developed desilting technology set to cause a stir

DAVID MAHLOBO The deputy Water and Sanitation Minister urged delegates to change their relationship and attitude with water as it is a scarce resource

OFFICIAL HANDOVER The demonstration showcased the Vortex Settling Basin’s unique capacity to tackle one of South Africa’s most pressing water infrastructure challenges, siltation

HOMEGROWN SUCCESS The Vortex Settling Basin was developed in South Africa through WRC research, refined through practical lab testing and is now being demonstrated in the field

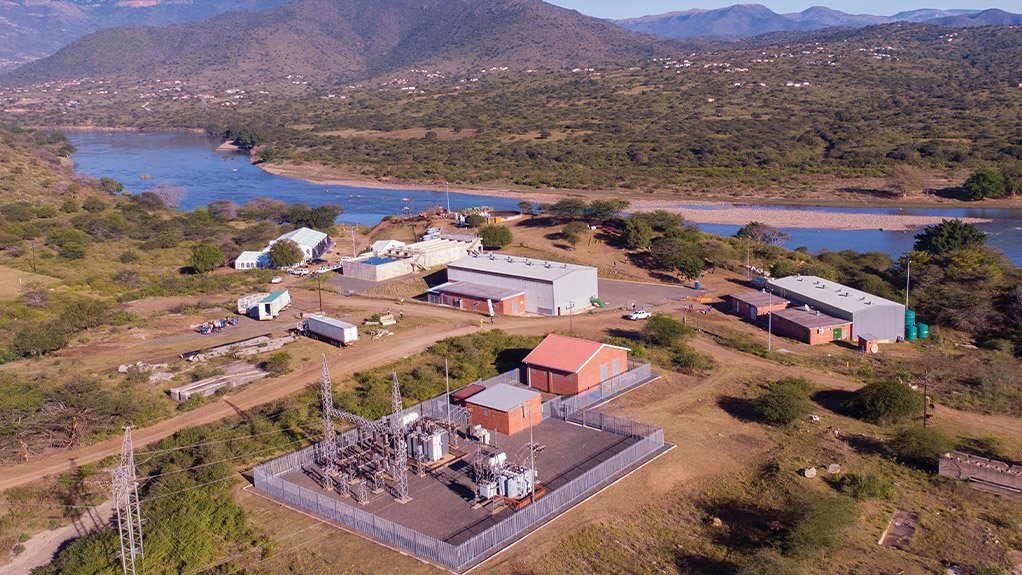

The Water Research Commission ( WRC), in partnership with the Department of Water and Sanitation (DWS), m a r ke d a significant milestone with the official handover of the Vortex Settling Basin (VSB) demonstration plant at the Thukela River abstraction works in Middledrift, Madungela, Nkandla, KwaZulu-Natal on June 12, 2025. The event marked the beginning of the live demonstration phase for this innovative sediment removal technology, demonstrated under the National Dam Siltation Management (NatSilt) Programme. The demonstration showcased the VSB’s unique capacity to tackle one of South Africa’s most pressing water infrastructure challenges, siltation. In rural and agricultural settings like Nkandla, sediment-laden water contributes to pump damage, clogged irrigation systems, higher maintenance costs, and reduced infrastructure lifespan. The VSB, a gravity-driven, low-energy solution, was developed specifically to address these issues by removing non-cohesive sediment before it enters downstream infrastructure.

The demonstration site was carefully chosen downstream of the Spioenkop dam, where sediment concentrations are high, and raw water is directly abstracted from the Thukela river. Here, the VSB’s performance will be rigorously evaluated and compared with conventional systems such as hydro cyclones. Early lab trials showed the VSB achieving a sediment removal efficiency rate of over 90% for particles larger than 0.075 mm, with significantly lower water losses and maintenance requirements. WRC CEO Dr Jennifer Molwantwa highlighted that this demonstration is very important for the WRC as it translates theoretical scientific innovation into practice not only at the laboratory scale, but at a real practical scale.

Key benefits of the VSB technology include:

- No electricity required – powered purely by natural hydraulic flow

- High sediment removal efficiency

- Minimal water loss (about 8%)

- No moving parts, requiring minimal maintenance

- Scalable design adaptable to various capacity needs

Beyond technical innovation, the VSB initiative also delivers substantial socio-economic value through local job creation during the installation and maintenance phases, skills transfer and training for municipal staff and technicians, and support for local small businesses through sourcing and fabrication.

The VSB demonstration project is an initiative under the NatSilt Programme, which adopts an integrated, multidisciplinary approach to sediment management. More than just a technical intervention, the programme is designed to develop solutions to rehabilitate dams and catchments while embedding sustainability, climate resilience and capacity building at the heart of South Africa’s water sector. NatSilt takes a holistic, system-wide view, tackling upstream erosion, catchment degradation and infrastructure vulnerability through proactive and coordinated strategies. By addressing siltation not only at the dam wall but across the entire water value chain, the programme directly supports long-term water security. Its success lies in bridging the strategic, technical, ecological, operational and socioeconomic dimensions of sediment management, while also investing in skills development and institutional capacity. The VSB is a tangible example of this innovative, impact-driven approach.

The VSB story is a homegrown success, developed in South Africa through WRC research, refined through practical lab testing, and now demonstrated in the field. It is a testament to the WRC’s mission to transform research into scalable, real-world solutions that can be taken up by the water sector, showcasing full research to impact cycle, says senior project manager Lesego Gaegane. The initiative aligns with the WRC’s broader goals of advancing climate resilience, sustainability and local innovation. The VSB is not just a technological innovation, it is a symbol of what is possible when South African ingenuity, science and community needs intersect. It’s about proving that smarter solutions that are developed in South Africa are within our reach, right here at home”, says Gaegane.

Deputy Water and Sanitation Minister David Mahlobo delivered the keynote address and urged the delegates to change their relationship and attitude with water as it is a scarce resource, encouraging the efficient use of water.

The VSB has the potential to drive sustainable development and empower rural communities by stimulating local economies through its commercialisation and localisation, creating skilled jobs, supporting local manufacturing and fostering a new industry around its production and deployment, says technology transfer manager Thabo Mthombeni. Gaegane said that often international technology is imported and then tailored to the South African context; however, this South African developed technology is by South Africa for South Africa and this localisation effort not only reduces dependency on imported solutions but also fosters a sense of ownership within communities. Further, as the VSB gains recognition, it opens avenues for partnerships between government, the private sector and community organisations, ultimately ensuring that the benefits of improved water management are distributed equitably. Dr Kuria Kiringu emphasised that the VSB offers an ideal solution for small municipalities that cannot afford large-scale infrastructure. “The VSB is a buy-and-use system, no structural modifications are needed. You install it as is and it’s ready to operate. With no moving parts, no chemical requirements and minimal maintenance, it provides a low-cost, low-maintenance alternative that is practical and sustainable for resource-constrained municipalities.”

The handover event was attended by community leaders, traditional authorities, local government officials, technical experts and civil society representatives. Attendees participated in a live technology demonstration, site tour and discussions on the future of siltation management. Mahlobo further emphasised the urgency of investing in resilient, cost-effective infrastructure to meet the demands of a changing climate. The WRC plans to recommend the replication of the VSB model in other sediment-impacted catchments across the country, using lessons from this demonstration to refine operational guidelines and inform national policy. The VSB forms part of South Africa’s broader commitment to sustainable water resource management, circular economy principles and inclusive development.

Contact Details:

Tel: 012 761 9300

Email: lesegog@wrc.org.za

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation