Lubrication pump systems enhance hydraulic components

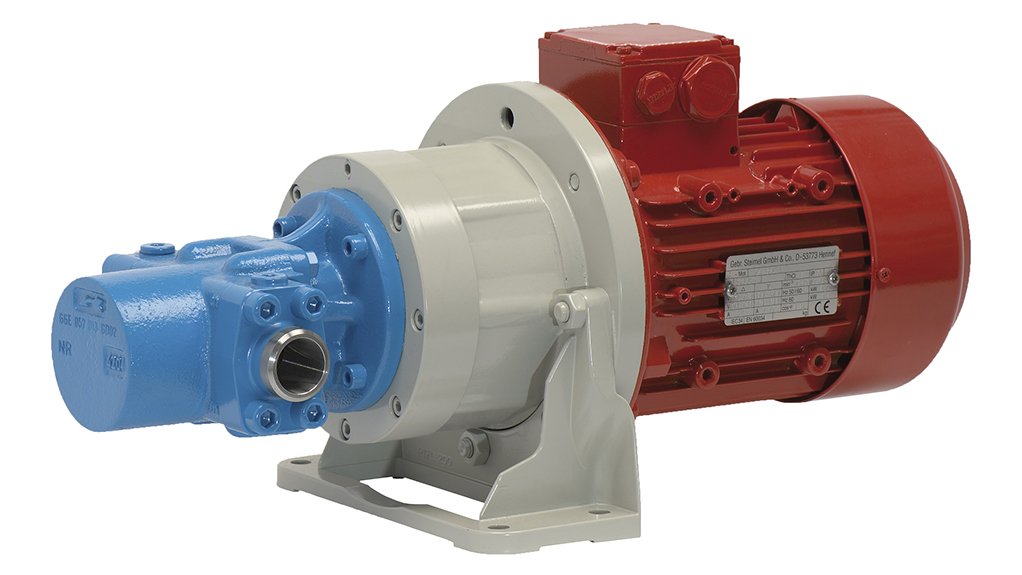

POWER PUMP SF gear pumps are used as circulation pumps in oil lube systems, kidney systems and for transferring oils

Industrial equipment supplier BMG’s range of Steimel lubricant and feed gear pumps – the SF series – is used mainly on oil lube systems in mines, steel works, power stations and general industry that make use of hydraulic systems.

“SF heavy duty pumps, which offer pulsation-free pumping delivery, are designed to pump any grade of lube oil, including high viscosity oils. These pumps are particularly suitable for transporting media with minimal lubricity, that is chemically compatible and does not contain solids,” says BMG national pump product manager Joe Pinheiro.

SF gear pumps are used as circulation pumps in oil lube systems, kidney systems and for transferring (off-loading or dispensing) of oils.

“These compact pumps are easy to disassemble and assemble. The standard design is supplied with a clockwise rotation, which is easily altered to anti-clockwise, by rotating the end cover plate by 180°. The direction of delivery flow will change at the same time. An optional feature is an adjustable pressure relief valve built into the housing, for short-term protection against pressure spikes.”

Optimum integration, with minimal tolerances of the pinions and gear wheels results in quiet, smooth running. The use of gear wheels with 12 teeth reduces delivery flow pulsation and minimises noise during operation. Shaft journals are mounted in composite bearing bushes which ensures continuous duty and extended service life. All pump sizes can be equipped with an anti-friction bearing at the driving end, to accommodate radial and axial forces.

Standard pumps have a maximum rotational speed of 1 800 rpm for a maximum viscosity up to 380 cst and a differential pressure up to 25 bar. The maximum permissible rotational speed depends on the viscosity or lubricity of the medium.

The higher the oil viscosity, the lower the speed. These pumps can handle media with a viscosity range from 5 cst to 50 000 cst and can withstand a temperature range between –40 ºC and +250 ºC.

Also, in the Steimel range are SF ATEX gear pumps, which provide a high degree of safety in potentially explosive environments.

Type SF M feed pumps, with a magnetic coupling, are hermetically sealed and can operate safely in applications at elevated temperatures and withstand media that are difficult to seal.

BMG also supplies the Steimel feed pump T series on request. These rotary gear pumps, which are designed to transport almost all media, can be used to maximum rotational speeds of 1 500 rpm, at pressures up to 16 bar.

Steimel Model B lubricant and feed pumps are designed to efficiently handle highly fluid media, like waste oils, greases, hardening and hydraulic oils, resins, lubricating greases and oils, as well as turbine and thermal oils.

These pumps have a permissible excess pressure up to 50 bar, a viscosity range up to 5 000 cP and a displacement from 2 to 75 cm³/rotation.

BMG offers a technical advisory service to ensure selection of the most suitable pump size for every specific application. The company supports this range with a spares facility and 24-hour maintenance service throughout Africa.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation