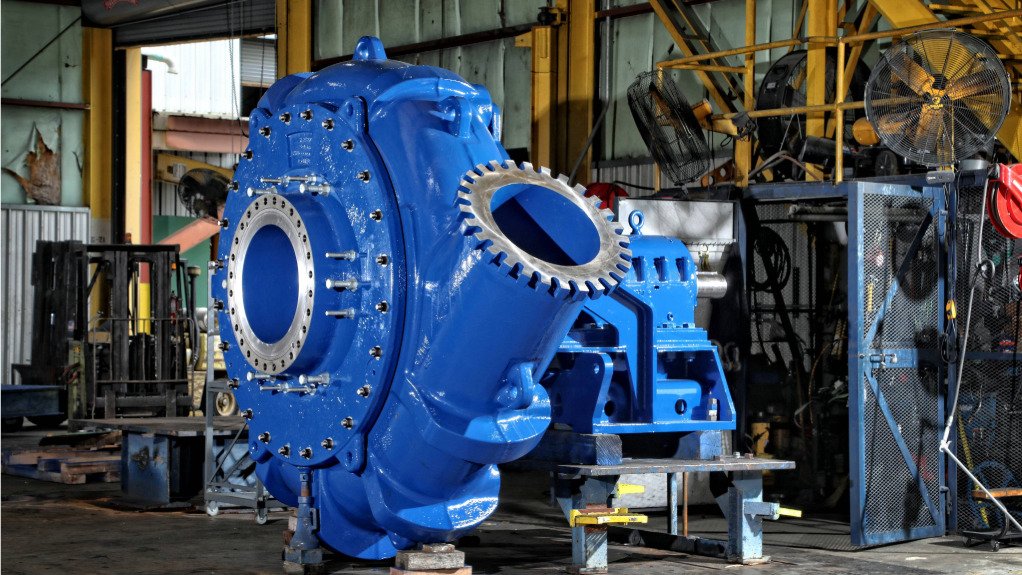

Miners standardising on mill pumps for cyclone use

ENHANCED PERFORMANCE The MDX pump delivers improved performance in terms of flow rates and pressure, crucial for efficient mill operation

Outperforming other pumps, often by two to four times in certain cases, pumps and valves supplier KSB Pumps and Valves South Africa reports many of its customers are now specifying the mill duty extra heavy (MDX) pump for new facilities and expansions, with several standardising on the MDX for their cyclone feed applications owing to the pump’s “quality wear performance and ease of maintenance”.

In particular, KSB highlights the MDX’s adjustable suction liner, which allows for nose gap adjustments while the pump is running.

In 2008, the company notes, its GIW MDX pump represented a major leap forward in mill duty applications, with the MDX being “meticulously designed from the ground up as a leading” mill pump for cyclone feed applications.

The MDX pump incorporates innovative features such as an adjustable suction liner, thicker sections for improved wear life and oversized shrouds for superior performance.

The company has remained closely engaged with customers, using their feedback to continuously improve the MDX design since its introduction to the market.

In 2009, the introduction of Endurasite and Enduraclad materials provided additional paths to enhance wear performance and by 2011, full pump lift capabilities were introduced even for the largest pumps up to the MDX 750.

The modular wet-end introduced in 2012 reduced the time required to replace a complete pump wet-end, while by 2014, further hydraulic improvements were made, including adding 35% more wear material to the impeller nose and optimising casing thickness.

These advancements harmonised the wear life of all key wet-end components, creating a consistent hydraulic design approach for larger models from the MDX 400 to the MDX 750.

Additional design advancements are anticipated this year to enhance the hydraulics of smaller pumps in the 100 to 350 range.

Additional Upgrades

In 2018 the first remotely adjusted mechanical suction liner was installed, advancing the adjustment of impeller nose clearance by enhancing wear performance and reducing maintenance time.

This was followed by the installation of the first advanced slurry pump wear monitoring technology – SLYsight – in 2021. SLYsight uses sensors to provide real-time data on pump wear, optimising maintenance schedules and extending pump life.

These features have enhanced the maintenance-friendly aspects of the MDX range, thereby enabling real-time data collection on pump operation, wear and nose clearance settings. This data, previously requiring planned maintenance shutdowns, can now be collected in real time, providing operators with new tools to optimise equipment use.

Looking ahead, KSB GIW is leveraging its prime foundry capabilities to meet the market demand for larger mill duty pumps. With this, the development of the MDX 850 will take full advantage of the expanded foundry’s capacity.

Additionally, the new KSB Internet of Things and Automation Lab in Grovetown, Georgia, in the US, will accelerate the development of digital products.

Plans include a handheld version of SLYsight and a user dashboard for on-demand data to optimise equipment performance.

These initiatives will introduce new features to the market, ensuring the MDX product line remains ahead of the curve and continues to offer enhanced performances, KSB reports.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation