Mitigating the environmental effects of opencast mining

LEON JANSE VAN RENSBURG South Africa’s environmental legislation and sustainable-practice models have made it possible to effectively manage the environmental impact of the country’s opencast mining sector

Opencast mining operations in South Africa remain one of the industry’s main contributors to short- and long-term environmental damage, as they have a direct and cumulative impact on the air, water, soil and visual quality of the environment surrounding opencast mines, says Johannesburg-based environmental management company I-CAT Environmental Solutions.

The dust generated at opencast mining operations can have serious health and pollution impacts if these operations are not properly managed and mitigated, says I-CAT environmental officer Leon Janse van Rensburg.

“Opencast mining also impacts negatively on water quality, owing to the contamination of groundwater sources, the pollution of surface water bodies through the processing of raw ore, mines’ dewatering processes and waste generated through the process life cycle,” he says.

Janse van Rensburg highlights that opencast mining activities create a significant amount of dust, adding that the degradation of the visual quality of a mining area often brings with it serious health impacts – such as eye and lung problems – and social impacts in the long term.

“However, South Africa’s environmental legislation and sustainable-practice models have made it possible to effectively manage the environmental impact of the country’s opencast mining sector and for the sector to include environmental aspects in the decision-making process.”

He adds that there is still some concern from the private and the public sectors about the mining industry’s implementation and governance of environmental policies and commitments.

Challenges and Solutions

The major environmental concerns around opencast mining include the generation of dust through blasting, raw-ore haulage and processing activities, which have serious impacts on the air quality at opencast mines and on health, and the ambient air quality surrounding opencast mines.

“Dust generated by haulage roads can account for up to 80% of the total dust being emitted at an opencast mine,” says Janse van Rensburg.

I-CAT has developed a range of nonbitumen- based dust palliatives to effectively manage dust emitted from the haulage roads, as well as dust-suppression misting systems to mitigate dust emissions associated with the crushing and screening of opencast mining ore.

“In addition to our dust-mitigating products and services, our water solutions division offers state-of-the-art water filtration and purification equipment, services and tech- nologies,” adds Janse van Rensburg.

I-CAT has installed several filtration systems at mines in Zambia and South Africa to bring process water to a standard suitable for discharging or for recycling.

The company also has an environmental consultancy division that offers a range of consulting services, including environmental management plan development, legal compliance audits, environmental-impact assessments and licensing applications.

Meanwhile, Janse van Rensburg says opencast coal mines in Mpumalanga and iron-ore and manganese opencast mines in the Northern Cape have been identified as significant areas of concern in terms of environmental damage caused by opencast mining activities.

“The Northern Cape is a water-scarce region and, with mining activities set to expand in the area, the impact of opencast mining on the water quality and quantity is of great environmental concern.

“The loss of habitat for sustainable agri- culture and biodiversity conservation areas owing to opencast coal mining in Mpumalanga is also of great concern in environmental circles,” he adds.

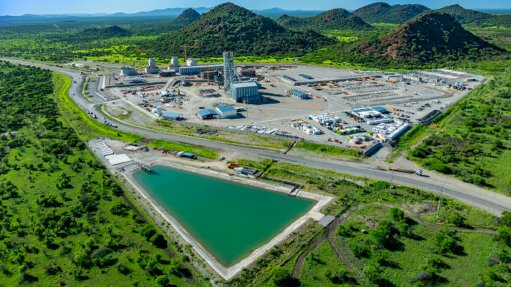

I-CAT is currently contracted to provide an end-to-end dust solution for the secondary roads surrounding iron-ore major Kumba Iron Ore’s Northern Cape-based Sishen mine. This includes monitoring and managing dust emissions from secondary sources such as stockpiling.

Moreover, I-CAT dust palliatives reduce the amount of water needed to effectively manage dust emissions. “Although the project for Kumba is not our most recent project, it certainly is our largest,” says Janse van Rensburg.

Some of I-CAT’s more recent projects include iron-ore miner Assmang’s Khumani iron-ore mine, in the Northern Cape. “This contract was acquired through our sister company in Kuruman, E-CAT Environmental Consulting and Trading,” he adds.

Janse van Rensburg further highlights base metals miner First Quantum Minerals’ Kansanshi copper mine, in Solwezi, Zambia, and black-empowered platinum miner Platimin’s Pilanesberg platinum mine, in Pilanesberg, as other recent I-CAT clients who contracted the company to provide a total dust solution for secondary haulage roads.

“Our services include dust monitoring and reporting, product supply, storage and management, and solution development for identified problem areas.”

Meanwhile, Janse van Rensburg tells Mining Weekly that I-CAT has developed a water- filling point management solution, called the radio frequency identification system (RFID) system.

“This system eliminates operator safety concerns, water spillage and wasting. It also increases productivity, as it saves time during the refilling of water bowsers and eliminates environmental concerns resulting from water and product spillage around filling points,” he notes.

Janse van Rensburg describes the system as “revolutionary”, in that it is the first of its kind to automatically identify a vehicle arriving at the filling point and measure the vehicle’s capacity and current levels of water.

It is also the first system to use cameras and on-board monitors to perfectly align the water bowser with the gooseneck without the operator having to leave the vehicle cab. The system also automatically starts and stops water and dosage pumps so that tanks can be filled to the correct levels.

Janse van Rensburg believes that the future of opencast mining depends on tech- nology like the RFID system being used to mine ore more efficiently, safely and in an environment-friendly way.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation