New research shows South Africa well-placed to export ‘green iron’ to EU

Initial research conducted for the Deep Decarbonisation Pathways (DDP) project in collaboration with the National Business Initiative (NBI) indicates that there is an emerging opportunity for South Africa to produce so-called “green iron” for export to international steelmakers seeking to transition away from the use of carbon-intensive coking coal in the production of the basic material.

The green-iron research forms part of a broader initiative – involving NBI, Business Unity South Africa and the Boston Consulting Group – to develop decarbonisation pathways for domestic industry that could also support the country’s proposed “just transition” to a more climate-resilient economy.

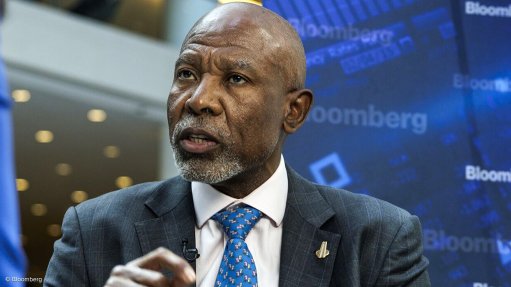

The initial findings, which were presented by SA DDP lead Hilton Trollip and Bryce McCall of the UCT Energy Systems Research Group this week, indicate that it will be cheaper to produce green iron in South Africa, owing to the country’s “abundant and very low-cost renewable energy potential” relative to many other territories, including the European Union (EU).

Should green-iron technologies, such as hydrogen direct-reduced iron (HDRI), be proven commercially over the coming decade, dedicated renewable-energy plants could be developed to produce green hydrogen through a process known as electrolysis, which uses electricity to split water into hydrogen and oxygen.

The hydrogen could then be used to convert South African iron-ore into HDRI and used by those international steelmakers with net-zero emission commitments to produce carbon-free steel.

Green iron will cost more than conventional technologies at first, but demand is nevertheless anticipated to be strong in markets where end-users, such as automakers, or governments have made specific decarbonisation commitments and are prepared to pay a price premium for steel with zero embodied emissions.

“Commercial-scale green iron plants have recently been announced to begin operating in the EU from between 2024 and 2030,” Trollip said, during a webinar attended by several European ambassadors and co-hosted by French thinktank IDDRI.

Government policy is likely to play a key role in supporting these commercialisation activities, with the EU having created ‘lead markets’ to drive innovation by providing substantial support for technology research, development and demonstration, protecting its markets and creating demand for premium priced products to support the demonstration and commercialisation of new technologies.

“The production of a green iron at a South African location, for export to the EU, could have substantial financial and economic benefits for both South Africa and Europe as it will reduce the overall cost of EU decarbonisation while making its steel industry more competitive.”

As the technology matures, South Africa could begin integrating green iron into its own domestic steelmaking processes.

“South Africa is not in the same position as the EU when it comes to creating a domestic market to warrant the large lumpy investment involved in establishing a green-iron plant,” Trollip argues, adding that the production of green iron for export could, however, be a stepping stone on the path to steel decarbonisation in South Africa.

“Green iron is an opportunity for South Africa to export beneficiated renewable energy embodied in beneficiated domestic iron-ore, while hugely increasing the value of this iron-ore.”

Prospects for producing green iron and steel were also flagged in a recent report into the potential for green hydrogen, produced by the Council for Scientific and Industrial Research.

The report argues that ArcelorMittal South Africa’s mothballed Saldanha steel plant, on the West Coast, includes a direct reduced iron plant and could be modified to be supplied by green hydrogen, to produce material that could be shipped to Europe.

“This would provide a new business model for a plant that was unable to compete with cheap Chinese steel supply, and would be synergistic with the Saldanha port, now reconfigured for green hydrogen and powerfuels production and export.”

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation