New soluble varnish removal range available in Africa

HY-PRO SOLUBLE VARNISH REMOVAL SYSTEM The Soluble Varnish Removal system attacks the source of the varnish problem on a molecular level, removing the oxidation by-products that form varnish deposits

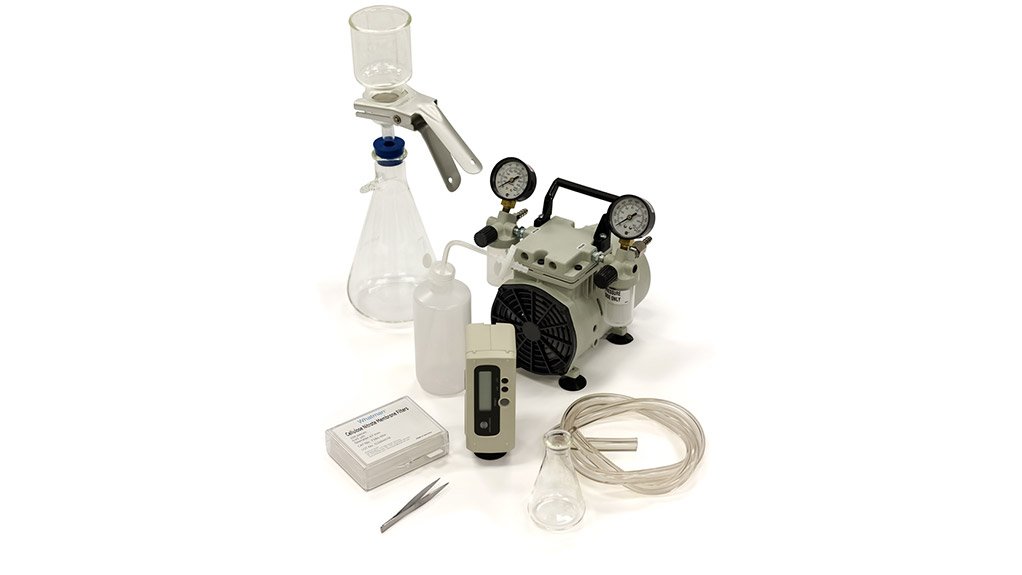

VARNISH TEST KITS Varnish Test Kits intended for long-term repeated use in-house by customers, provide a quicker status report of fluids being analysed

The new Hy-Pro Soluble Varnish Removal (SVR) system – now available from Hytec Fluid Technology (HFT) – offers complete recovery and maintenance for turbine lubricants. The SVR will be available across Africa through HFT.

The prevalence and potential economic impact of varnishing in industrial applications is so significant that original-equipment manufacturers recommend the use of varnish removal systems from the outset to mitigate risk, according to HFT industrial filtration divisional manager Wynand Kapp.

“There was a need for a simple, easy-to-use product to prevent and remove dissolved and breakdown products in lubricants, which, if allowed to accumulate, form varnish,” explains Kapp.

He states that SVR attacks the source of the varnish problem on a molecular level, removing the oxidation by-products that form varnish deposits. SVR removes acid to improve oxidative stability, slow oxidation rate and reduce varnish production. SVR systems feature “industry leading” filter purification technology for soluble varnish contaminant removal, emphasises Kapp.

He stresses that, “unlike competing systems, SVR purifies 100% of reservoir volume each day”.

Ion Charge Bonding (ICB) is a family of ion exchange resin technologies that is used to purify industrial lubricants, such as those mentioned. ICB has widely been used to purify turbine and compressor lubricants as well as phosphate ester fluids. ICB restores demulsibility during normal turbine operation without damaging additives. He adds that SVK systems all make use of specifically formulated ICB resins that improve machine performance, increase longevity and minimise downtime associated with machine failure.

Kapp highlights a case in which a site with a steam turbine was experiencing varnish build-up on mechanical components. He states that three months after installing an SVR system, varnish deposits had been absorbed back into the lubricant, adding that after four months of operation, a decreasing trend began, cleansing varnished mechanical components. SVR treatment reduced the fluid varnish potential value to below ten over the subsequent three months, enthuses Kapp.

He states that HFT also offers Varnish Test Kits (VTK) intended for long-term repeated use in-house by customers. The available VTK has an upgraded spectrometer for ease in testing and accuracy with an expected life cycle of more than five years. He says that only annual soft calibration and biannual hard calibration is required.

“Testing in-house provides a quicker status report of fluids being analysed,” says Kapp. “Specifically calibrated for Membrane Patch Colorimetry testing according to international ASTM requirements, which form an essential part of turbine and compressor lubricant management, the VTK assists in developing and maintaining a proactive maintenance schedule.”

Kapp assures that the company’s SVR customers work with industry experts to receive comprehensive oil analysis and results interpretation.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation