Oil-monitoring tech boosts maintenance

OIL MONITORING The ATAJO OnEdge product suite was developed to assist mines in mitigating maintenance issues, predicting equipment failures and enhancing machinery performance

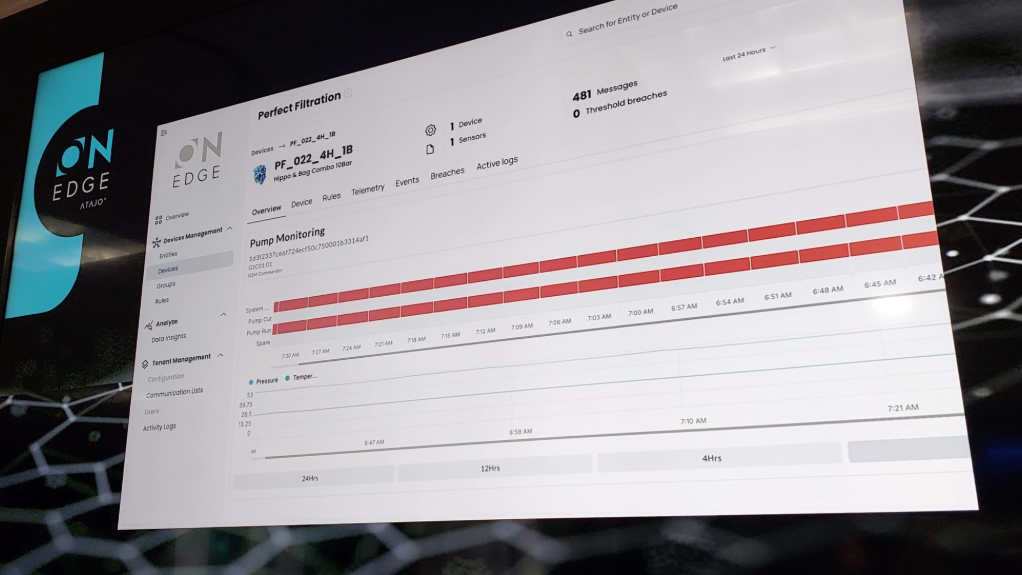

OPERATIONS EFFICIENCY Marco Capazario showing attendees of the launch event how ATAJO OnEdge works with the Perfect Filtration system

South Africa-based digital solutions provider Britehouse Mobility, and its partner Perfect Filtration, are optimising plant efficiency and reliability of mobile mining equipment with the ATAJO OnEdge live conditioning monitoring digital product suite.

The platform – launched last month in Johannesburg – comprises real-time oil sensors and software which can proficiently monitor and analyse oil contamination issues.

Mining operations have to deal with challenges such as keeping abreast of maintenance issues, predicting equipment failures and enhancing machinery performance.

The ATAJO OnEdge product suite was developed to assist mines in mitigating these challenges, because, traditionally, mining plants could only be assessed during scheduled maintenance, leading to limited condition monitoring and potentially resulting in significant losses in production and a reduction in the availability of machinery.

The product suite is useful for trackless mobile mining equipment in both opencast and underground mining operations. It is designed for production equipment such as drill rigs, loaders and dumpers, for real-time oil contamination detection, explains Britehouse Mobility business unit lead and manager Marco Capazario.

The live condition monitoring element of ATAJO OnEdge uses sensor technology to monitor oil that is used in machinery, centralising the data, making it easy for mining operators to detect issues resulting from oil contamination.

The centralised data is processed, and exceptions are communicated through a mobile app, email or WhatsApp, consequently enabling mine operators to make informed decisions about oil contamination issues and the ability to track the consequential action taken.

The data can be accessed in near real-time through the cloud, or by on-site personnel in instances whereby users opt not to have potentially sensitive information on Web-based servers.

“It’s really about streamlining the data and providing [reliability engineers] with relevant data that is meaningful to them and their function within engineering,” explains Capazario.

All-round Operation Enhancement Benefits

Various experts and technicians can consult on ways of dealing with oil or diesel contamination issues, owing to ATAJO OnEdge’s high-quality data that is captured by the real-time sensors.

Mining operations can, therefore, implement the data-driven decision-making platform facilitated by the product suite to reduce the costs incurred because of untimely or late oil contamination detection.

The product suite also allows for identifying trends in the performance of oil and diesel in machinery, such as exposure to contamination and the contamination type, as well as the severity and duration of the contamination.

This enables engineers or technicians to take immediate action and establish preventative measures to decrease the likelihood of similar contamination occurrences.

The product suite can also be integrated with existing enterprise asset management and enterprise resource planning systems.

These benefits serve to help mine operators reduce maintenance costs, increase equipment longevity and uptime, and improve profitability.

Capazario says the ATAJO OnEdge has been thoroughly tested through extensive research and development projects at an iron-ore and manganese mine, in the Northern Cape, for about five years.

Consequently, 120 ATAJO OnEdge system interfaces are being used on equipment, including drill rigs, dump trucks and loaders, for engines, transmissions and hydraulic systems.

Going forward, Britehouse Mobility and Perfect Filtration will focus on growing the footprint of the product suite.

“We are looking at ATAJO OnEdge in a very specific application – in terms of oil monitoring – which is quite a technical subject and a very detailed, highly specialised area. However, it can also be utilised in many other areas and aspects . . . I think that’s where we play a critical role,” concludes Capazario.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation