Platinum group metals have major ‘urban mining’ plus, Johnson Matthey highlights

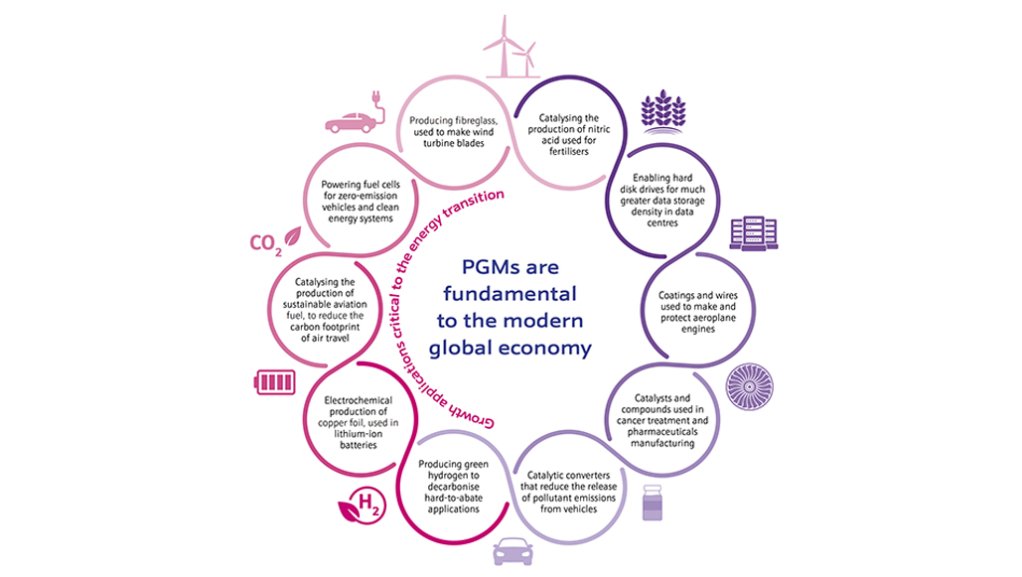

The many uses of platinum group metals.

Photo by Johnson Matthey

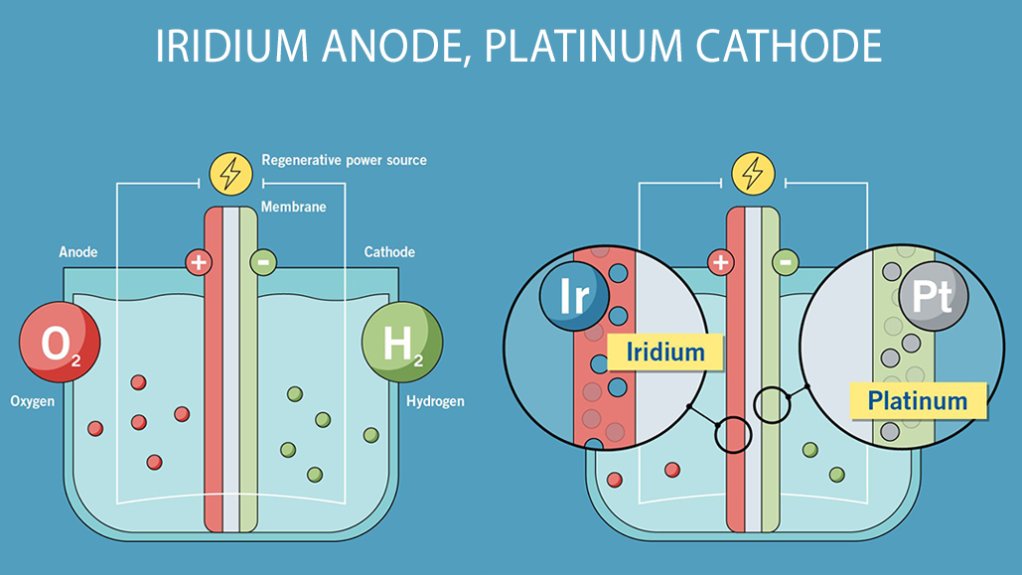

The importance contribution of PGMs.

Photo by Heraeus Precious Metals

JOHANNESBURG (miningweekly.com) – Platinum group metals (PGMs) – which are hosted and mined overwhelmingly in South Africa – have recycling rates approaching the 100% mark in some applications, with the carbon intensity of PGM recycling some 97% lower than that of newly mined metal.

PGM products are used in a vast number of industrial applications where technology and performance are key, and the recovery of platinum, palladium, rhodium, ruthenium, and iridium has given rise to what can appropriately be described as a substantial ‘urban mining’ advantage.

Johnson Matthey, a company founded in 1817, which has a long-standing South African presence in nearby Germiston, reports in a White Paper that the growing need for PGMs cannot be met through conventional below-surface mining alone.

As a refiner of recycled PGMs, a participant in global PGM supply chains and trade, and a provider of PGM market intelligence, Johnson Matthey’s experience is an eyeopener for the many who are currently working globally to establish circularity for all metals and materials to meet lower-carbon imperatives.

Earlier this month, Johnson Matthey and Bosch agreed to collaboratively develop zero-emission hydrogen technology, involving the generation of green hydrogen through PGM-based electrolysis and the conversion of that green hydrogen to clean electricity through fuel cells that also make use of PGMs.

Hydrogen fuel cells are electrochemical devices that combine hydrogen and oxygen to generate electricity. As pure water is the only by-product, fuel cell electric vehicles are a zero-emission option.

With Bosch, catalyst coated membranes for use in fuel cell stacks will be advanced.

Catalyst coated membranes will be used in integrated, compact and scalable fuel cell power modules for commercial vehicles, designed for longer distances.

Interestingly, on Tuesday, February 11, Johnson Matthey unveiled a new way of getting more from hydrogen production, through the use of its trade-marked Catacel catalyst.

By reducing energy consumption and increasing feedstock efficiency, this catalyst introduces a way that hydrogen production can be scaled more cost effectively.

As the world searches for cleaner energy solutions, green hydrogen is emerging with progressive viability as the genuine no-carbon option, amid the Danish government announcing that it plans to supply green hydrogen to Germany by 2030.

The green hydrogen will be piped from Esbjerg to the German border as part of a package of measures that will support the hydrogen and offshore wind markets. Preparations to ensure the export of the hydrogen in five years time are already in motion.

“Denmark has an opportunity and an obligation to take part in kick-starting the emerging hydrogen market in Europe. This is the beginning, not the end,” Danish Climate, Energy and Utilities Minister Lars Aagaard stated in a release accessed by Mining Weekly.

Meanwhile, filtration company Donaldson is partnering Daimler Truck North America in the SuperTruck III hydrogen fuel cell project to highlight its advanced air filter technology in the next-generation vehicle.

As of February, China's green hydrogen and green ammonia projects have hit the 764 mark, with some projects having already moved to the electrolyser procurement stage, Green Power VP Yong Ye reported on LinkedIn.

Of projects detailed, two have capacities of 100 000 t/d, one with more than 90 000 t/d and five with above 20 000 t/d, against the backdrop of global climate change challenges, energy supply concerns and resource constraints being considerably pressing.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation