Pump wear technology critical to mining industry

Pump wear technology is playing an increasingly significant role in monitoring and maintaining pump performance, ensuring the efficient operation of slurry pumps in the mining industry.

KSB Pumps and Valves market area manager: mining Jacques Pretorius explains that slurry pumps transport abrasive and corrosive mixtures in mining operations, which inevitably results in wearing of sacrificial components. Pretorius notes that it is crucial for slurry pump users to manage the results of this wear to maintain optimum pump efficiency. Although traditional methods of monitoring and managing pump wear through manual inspections and scheduled maintenance are common, these methods have limitations such as time and resource expenditure.

“Additionally, such approaches are reactive, meaning wear is often only identified after it has impacted pump efficiency leading to higher maintenance costs and potential downtime,” adds Pretorius.

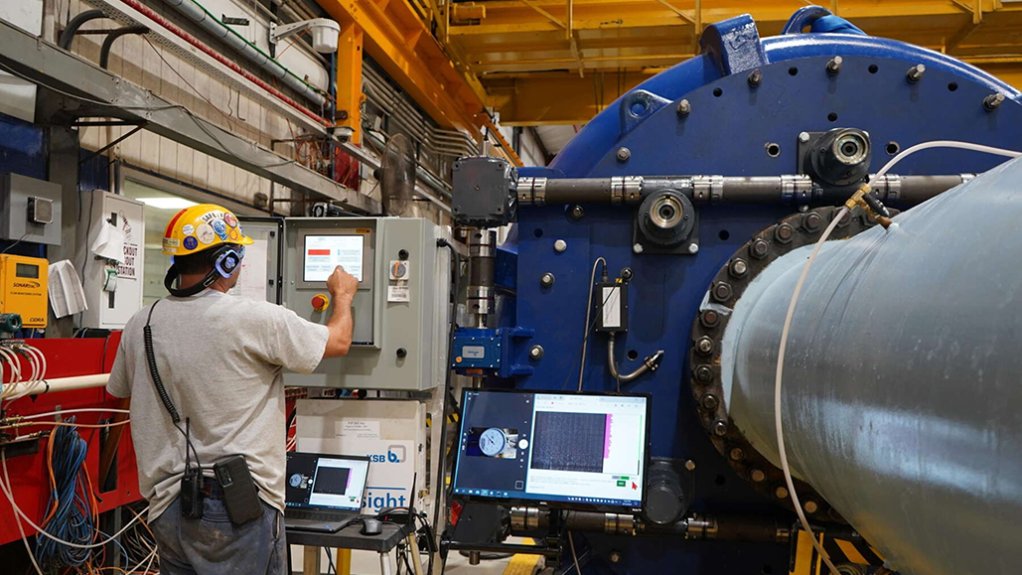

A new solution in the industry is the KSB GIW SLYsight technology, described as an advanced slurry pump wear monitoring technology that is changing the way pump wear is detected and managed, leading to improved pump performance with longer equipment lifespans.

“KSB GIW SLYsight utilises custom sensors, in strategic locations, to measure the actual wear rate of a slurry pump’s parts including the internal clearance between the suction liner and the impeller - also known as the ‘nose gap’. The data collected by the sensors as the pump runs is shared through periodic reports”.

“This enhanced monitoring system delivers data during nose gap adjustments that not only contributes to the pump’s maximum wear life but also enables operators to make an efficient and safe adjustment while the pump is operating,” says Pretorius.

He adds that integrating this technology can prevent unforeseen shutdowns and streamline operations. At the same time, the technology helps avoid premature replacement of sacrificial components before they reach their maximum service life.

An additional advantage is its ability to supply maintenance teams with data that enhances the understanding and management of pumping equipment wear through visual data reports and monitoring capabilities.

The technology employs real-time, objective monitoring of wear and enables more informed decision-making that can pre-emptively counter potential wear and tear issues before they escalate.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation