Real-time tailoring of explosive energy a reality

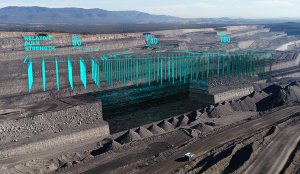

BENCH IT Blasting has traditionally been considered in three dimensions (width, length and depth); however, decisions on the application of explosives are often one-dimensional

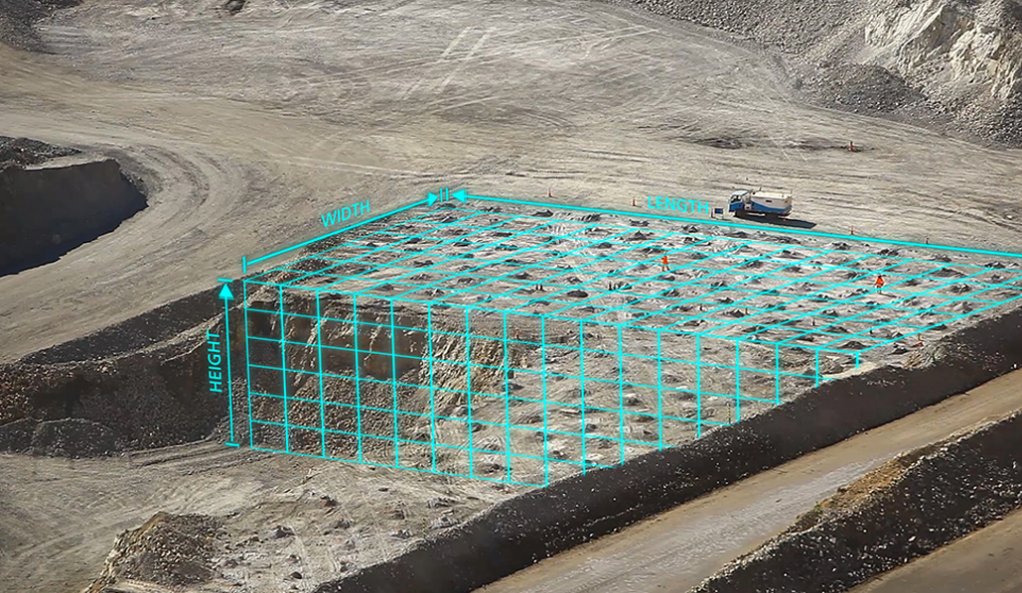

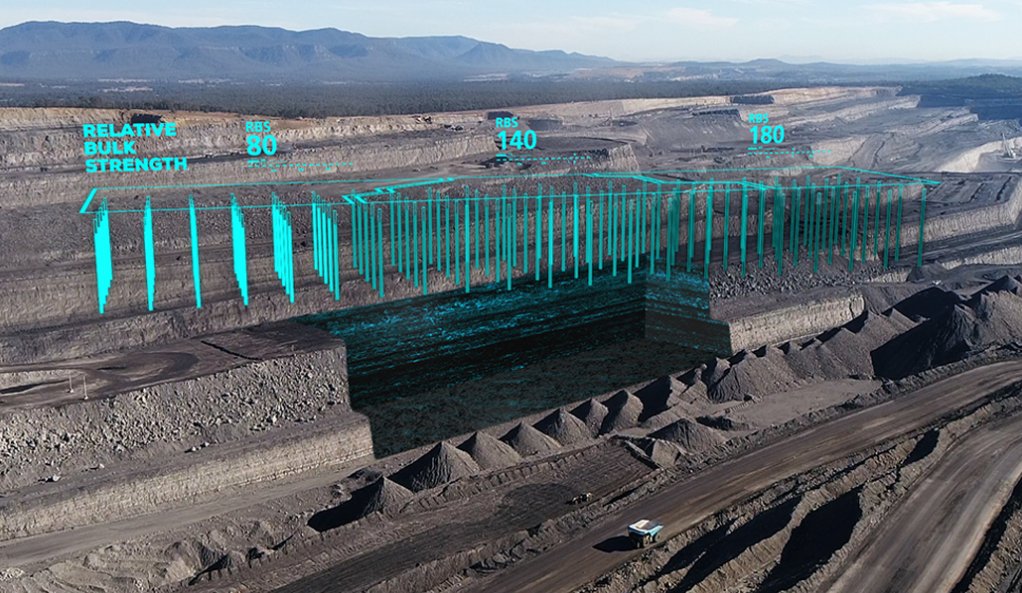

BULK MUSCLE Relative bulk strength is a measure of the energy of an explosive, per unit volume

Mining and infrastructure solutions company Orica notes that its “revolutionary” 4D bulk system is available for surface mining, and is being trialled for underground mining, with subsequent market introduction planned for 2023.

4D capability, having been introduced to Australia and Indonesia in 2022, will be made globally available through 2023, with “foundation customers” being lined up across North and Latin America.

Released in September last year at MINExpo in Las Vegas, in the US, the 4D bulk system allows for the real-time tailoring of explosive energy, based on geology, across a blast.

Orica Europe, Middle East and Africa VP Victor Morales says blasting has typically been considered in three dimensions (width, length and depth), but blast application decisions were often one-dimensional, not accounting for differences in geology.

“This essentially means that the same explosive blend and product density are applied to every blast hole across a blast pattern.”

The 4D technology, meanwhile, enables the drill-and-blast engineer to design blasts based on the geology and the energy required, consequently allowing for the lowest cost explosives to be loaded while maximising blast outcomes, explains Morales.

Further, with 4D capability, formulated with Orica’s proprietary emulsion blended with ammonium nitrate porous prills, the company has enabled customers to access a wider range of energy explosives in wet, dewatered and dry blast holes, thereby delivering optimised explosive energy that is matched to the desired blast outcome.

The 4D bulk explosives can be loaded through pumped and augured methods, ensuring greater bench productivity through Orica’s fleet of 4D-enabled explosives delivery systems or mobile manufacturing units.

Key Benefits

Morales states that 4D ensures that only the required amount of energy is applied to every blast hole, delivering consistent fragmentation for the lowest possible cost. This maximises fragmentation, which can increase productivity while reducing costs.

He says this consistent fragmentation drives excavation productivity and downstream processing, which often translates to increased throughput, and/or reduced energy consumption.

Another benefit is that 4D’s increasing energy facilitates the expansion of blast patterns allowing for more efficient use of drills and on-bench personnel.

4D also loads lower energy products into wet holes, which are better matched in terms of rock strength, while maintaining effective water resistance and reducing the risk of fumes caused by overblasting in soft geology.

Further, Morales notes that the bulk technology delivers up to 43% reduction in relative bulk strength for soft-rock or technical applications, and up to 23% more energy for hard-rock applications, compared to Orica’s current Relative Bulk Strength-based product ranges.

Additionally, when integrated with Orica’s BlastIQ suite of digital blast optimisation technologies, customers can gain a deeper understanding of the geology and blast hole conditions to maximise 4D capabilities and effectiveness.

“The development of 4D reinforces Orica’s commitment to technological innovation and is in line with our customer-centric technology roadmap and vision of transforming drill-and-blast operations to unlock greater mining value, and create safer and more productive blast outcomes,” Morales concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation