Reduction of UPS system environmental impact

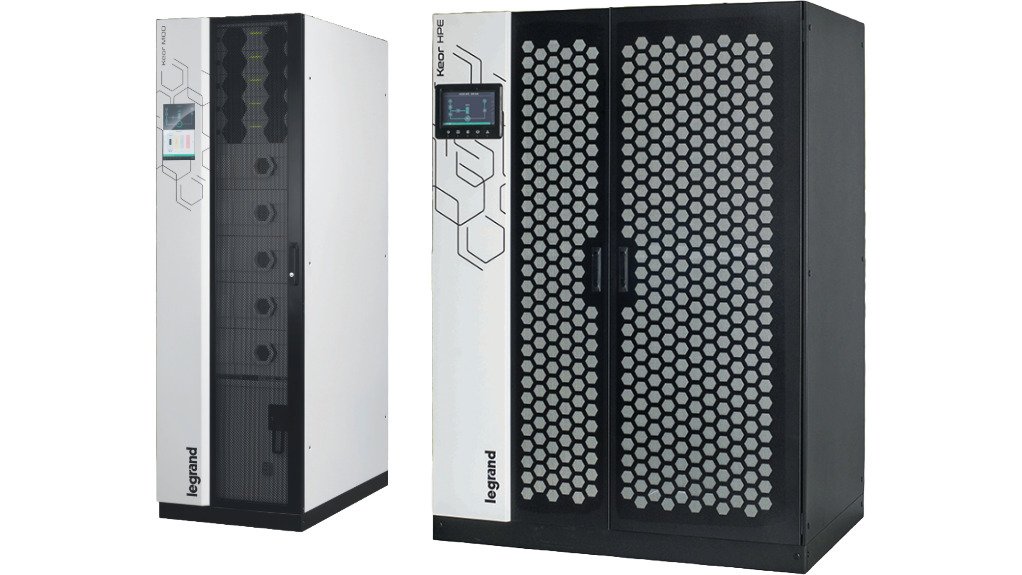

MODULAR DESIGN A modular design enables a greater efficiency in manufacturing, reducing material waste and extending the service life of the product

To commit to eco-sustainable solutions in all sectors of its business, including uninterrupted power supply (UPS) systems, digital building infrastructure specialist Legrand’s design specialists are determined to reduce the environmental impact of these power protection solutions.

The global team, which recognises the challenges associated with the energy consumption and material composition of UPS products, has adopted measures across the product life cycle to mitigate their footprint.

As part of its ongoing strategy to reduce environmental impact, Legrand continues to advance research and development efforts to improve the sustainability of UPS products.

The integration of circular economy principles, efficiency-driven design and rigorous environmenta-impact assessments, positions the company as leaders in promoting eco-conscious energy solutions.

Legrand’s approach begins with a pledge to eco-design, ensuring that UPS systems are developed with a focus on sustainability.

This involves the selection of a high proportion of materials sourced from the circular economy, the use of recyclable components and the minimisation of hazardous substances.

These design principles extend to packaging, which prioritises the use of single-material, recyclable content to facilitate disposal and recycling processes.

The company also places emphasis on adaptability and modularity in the design of its UPS systems.

It notes that a modular design enables greater efficiency in manufacturing, reducing material waste and extending the service life of the product through ease of replacement and “effortless” upgrades.

Moreover, the reduction of energy losses through optimised efficiency is a core consideration. High efficiency in UPS operation results in lower energy consumption and reduced cooling requirements, lowering the environmental impact of the product over its operational life.

Legrand adopts the Life Cycle Assessment (LCA) methodology to quantify the environmental impact at each stage of a UPS system’s lifecycle.

This evaluation considers raw material extraction, production, distribution, installation, use and end-of-life disposal. By incorporating the LCA approach, Legrand ensures that sustainability is factored into decision-making, from the initial design stage through to end-of-life considerations.

The company applies internationally recognised standards, including the greenhouse-gases (GHG) protocol to quantify GHG emissions and their sources.

Scope 1, 2 and 3 emissions are monitored, allowing for targeted reduction strategies that align with global sustainability goals.

Moreover, in adherence with stringent industry standards, Legrand’s UPS solutions comply with the International Electrotechnical Commission’s and the European Standard’s 62040 certification requirements, ensuring electromagnetic compatibility, performance efficiency and environmental responsibility.

Additionally, Legrand integrates the Product Environmental Profile certification and the European Commission’s Product Environmental Footprint methodology to enhance transparency in sustainability reporting.

The transportation and distribution of UPS products contribute to emissions and resource consumption. Legrand mitigates this impact by optimising logistics, reducing packaging waste and employing energy-efficient transportation methods.

According to Legrand, by reducing the distance between manufacturing facilities and distribution centres, the company reduces the carbon footprint associated with product delivery.

Installation and operational efficiency are also important considerations, and appropriate installation methods ensure that systems operate at optimal efficiency, reducing unnecessary energy consumption.

Legrand’s UPS solutions are designed to achieve high energy efficiency across a variety of load conditions, ensuring lower energy losses throughout the equipment’s operational life.

The use of advanced power management features further enhances efficiency, supporting lower energy consumption and reducing environmental impact.

End-of-life considerations are essential for ensuring that UPS systems do not contribute to electronic waste. Legrand’s approach to product life-cycle management includes strategies for responsible disposal, recycling and repurposing of materials.

Through the integration of sustainable practices across the product life cycle, from material selection to end-of-life management, Legrand reinforces its dedication to environmental responsibility.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation