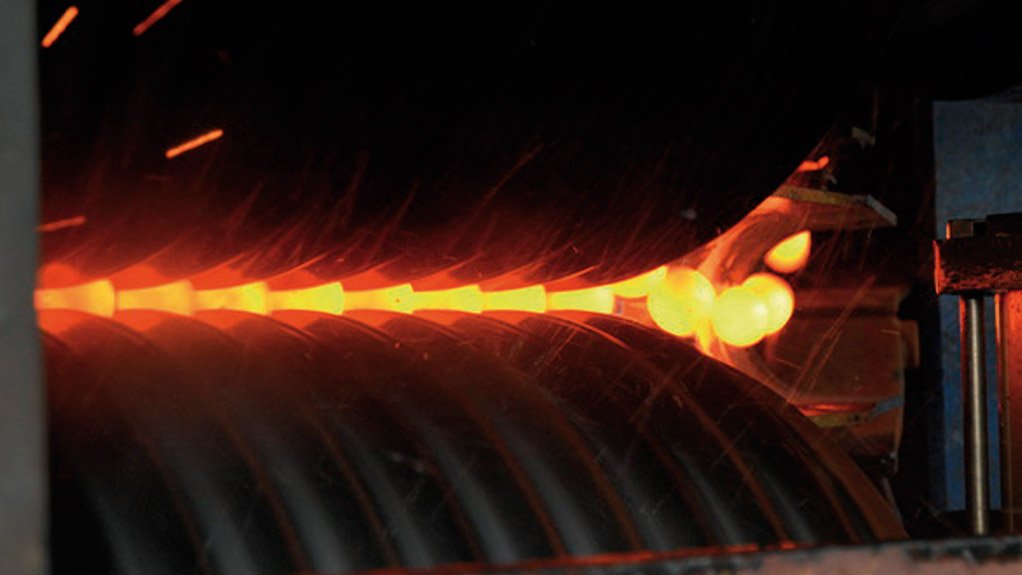

Scaw Metals hot-strip steel mill, South Africa – update

Photo by Scaw Metals

Name of the Project

Scaw Metals hot-strip steel mill.

Location

Scaw Metals’ Union Junction complex in Ekurhuleni, in Gauteng, South Africa.

Project Owner/s

Barnes Group acquired Scaw Metals in 2018.

Project Description

The project entails the construction of a state-of-the-art hot-strip steel mill.

The investment will increase Scaw’s steelmaking capacity from about 500 000 t/y to 750 000 t/y.

Scaw has previously produced only long steel products, but the investment under way will position it to produce long and flat products, with a 50:50 mix currently envisaged.

In addition, ArcelorMittal South Africa’s mothballing of the Saldanha Steel mill, in the Western Cape, has resulted in the closure of significant local capacity to produce thin-gauge hot-rolled coil (HRC), on which some domestic rerollers previously relied.

Based on state-of-the-art Danieli processing equipment, the Germiston plant will produce narrow- and medium-width HRC up to a metre, at gauges of between 1.2 mm and 6.0 mm.

The project entails the revamping of Scaw’s existing melt shop, which includes a new-generation electric arc furnace (EAF).

The melt shop will be supplied using a combination of scrap and direct reduced iron (DRI), produced using the mill’s existing kilns on site.

Potential Job Creation

The project is expected to generate a further 300 direct permanent jobs at Scaw and the Barnes Group, which already employs about 5 000 people.

Capital Expenditure

R5-billion, which has been 75% funded by Absa and Investec and 25% funded by the State-owned Industrial Development Corporation.

Planned Start/End Date

The first coil was cast in August 2024.

Latest Developments

The first HRC has been produced at Scaw Metals’ Union Junction complex, heralding the reintroduction of competition into South Africa’s flat-steel market.

The new flat-steel mill is the first to be built domestically since Saldanha Steel in the 1990s, but which has since been mothballed.

For Scaw, it adds HRC to the group’s primary steelmaking portfolio, which has hitherto consisted of only long-steel products.

As is the case with the long products produced by Scaw, the larger Barnes Group expects to absorb about half of the new mill’s output across its various downstream operations.

The balance will be sold to domestic customers that are currently mostly reliant on imported material for their tubing, shelving and re-rolling operations.

Barnes estimates that the plant will replace about R4-billion-worth of narrow-gauge steel imports yearly.

For South Africa, meanwhile, Barnes believes the investment will help address the current domestic manufacturing imbalance between flat and long steel.

Another advantage is the fact that the mill is producing flat and long steel that is regarded as “greener” than material being produced in blast furnaces.

This, owing to the lower carbon footprint associated with the EAF process, where direct emissions can be near zero if the electricity is sourced from renewable energy, and the fact that “circularity” is embedded through the use of scrap.

The group is continuing to assess options for improving the green credentials of its steel even further by integrating renewable electricity into its process.

Key Contracts, Suppliers and Consultants

ECS Associates (project management); Enza Construction and Trencon Construction (construction contract); Danieli (steel mill technology – the contract includes several components, including a medium-slab continuous caster and semicontinuous hot-strip mill, a reheating furnace and a brownfield water-treatment plant).

Contact Details for Project Information

Scaw Metals public affairs and communications Dudu Ndlovu, tel +27 11 621 1524 or email d.ndlovu@scaw.co.za.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation