Simplify your plant or mill gearbox checks from 15 steps to 5

This article has been supplied.

Instead of time-consuming “down days” to check gearbox oil levels in your plant or mill, Lubrication Engineers (LE) suggests visual on-the-run maintenance checks.

Mark Jones, Lubrication Reliability Consultant at LE for the Georgia region of the USA, says that traditionally, there are about 15 steps that need to be taken to check a gear box oil level. “First, you’d need to gather all the oil containers-jugs, galvanised cans, old bleach jugs, orange juice containers, rags, drain pans, and PPE in use,” he says. “Then they have to stop the machine or put it on hold, remove any safety guards or screens, find a ladder or arrange a lift to reach the gearbox if it’s high, put safety harnesses on, and get out their tools to remove the breather, level plug and drain plug. That’s all before they can even check the oil!”

Callum Ford, National Marketing Manager at LE South Africa, says Jones offers awareness training to LE lubrication consultants from around the world to help them simplify these sorts of procedures. “Once you actually get to checking the oil, there are about another 10 steps you’d have to take in a traditional setup without a lubrication reliability solution in place,” he says.

Jones agrees. “You have to take off the breather, unscrew the level plug and check to see if any oil comes out. If too much oil comes out, it means there’s friction or pressure in the gear box, causing oil to flow out the vent plug.”

Then, the technician will need to pour oil into the breather hole until it comes out of level plug. Once oil comes out, the technician will wipe up and clean up any oil that has dribbled on the side of the gear box or fallen on to floor, climb down the ladder or lift, return it to its proper place, remove any safety harnesses, replace safety guards or screens, take temperature for the baseline, and then travel to the next gearbox to do it all over again.

“The average time you’re looking at is about an hour per gear box,” says Jones. “If you have six or seven gear boxes, that’s an entire day gone.”

There are, however, modern lubrication products and offerings available that can drastically cut down on the time required to check gearbox oil. Items like oil sight glasses and oil level indicators give technicians quick visual insight into what’s happening with their lubricant at all times, while dessicant breathers remove humidity and tiny dust particles. “These measures help people to catch problems early on, by monitoring the clarity, colour, sediment and water contamination of their lubricants, and by protecting against contamination.”

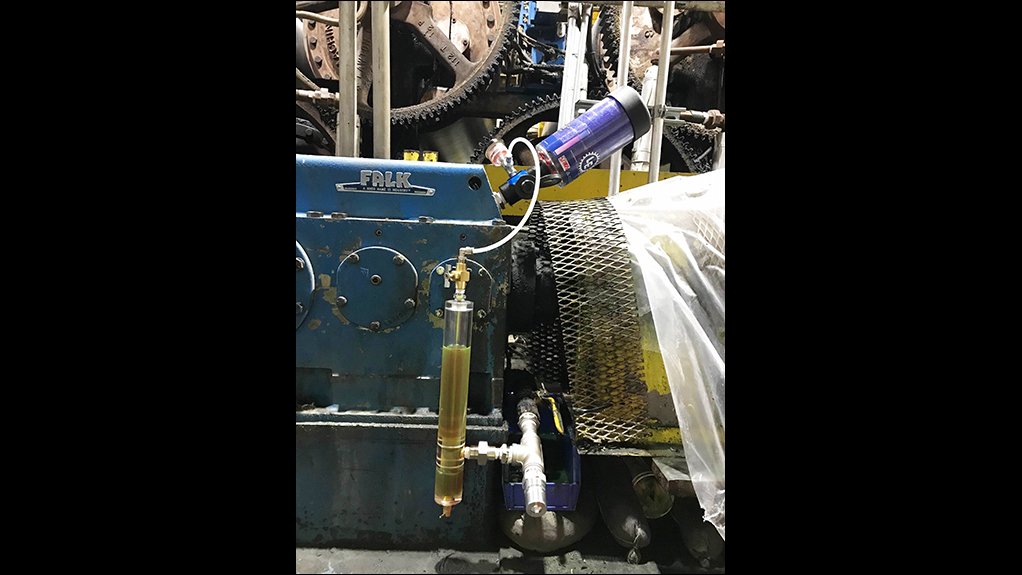

For this reason, LE has developed the LEX Gear Box Adaptor Kit, which includes all these components, as well as a temperature gun. With these components, the 15-step process can but cut down to just five.

“If you replace the vent plug with a LEX Gear Box Adaptor Kit, you can safely conduct checks while in production (without shutting off your machinery), in an on-the-run-check,” says Jones. “First, take the temperature of the gearbox with the thermal heat gun or IR gun. With an average temperature of 49 degrees Celsius or 120 degrees Fahrenheit, you’re good to go. Then check the colour of the Xclude breather to see if it is blue or pink. If it’s blue on top, check the sight glass for milk/water in the oil. Pull a sample to check for the source of water. You may need to filter with cart. If the breather is still blue, continue with the rest of the checks.”

This includes checking the vacuum indicator on the gearbox adaptor to see if it has been tripped to red, indicating that the breather is plugged and cannot breathe. If red, pull more plugs or replace the breather. If it’s not red, continue to the next check.

Check the Xclude sight glass for oil level, colour and clarity. If low on oil, use Xpel Colour coded containers to safely refill through the Xtract Gearbox Adaptor quick disconnect.

“These checks take about 5 minutes, and this includes adding oil” and changing a breather,” says Ford. “To do seven gearboxes will take under an hour, compared to a full day. We believe the decreased downtime, the improved safety and the sheer ease of doing routine checks will make the investment in the LEX Gearbox Adaptor Kit worthwhile for our customers.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation