Smarter valve design cuts downtime, reduces costs

PREDICTIVE MAINTENANCE KSB is increasing its focus on automation and predictive systems to support long-term plant efficiency and reliability

SMART VALVES KSB offers technologies such as its BOA-Tronic valve range which features smart valves that include built-in ultrasonic flow and temperature sensors

VALVE MAINTENANCE KSB now encourages valve maintenance and refurbishment, rather than full replacement

Smarter design and better materials used to manufacture valves used in mining applications can make a significant difference in not only plant performance but also in overall mine operating costs and operational reliability, says pumps and valves manufacturer KSB Pumps and Valves sales manager: valves Keith Hedges.

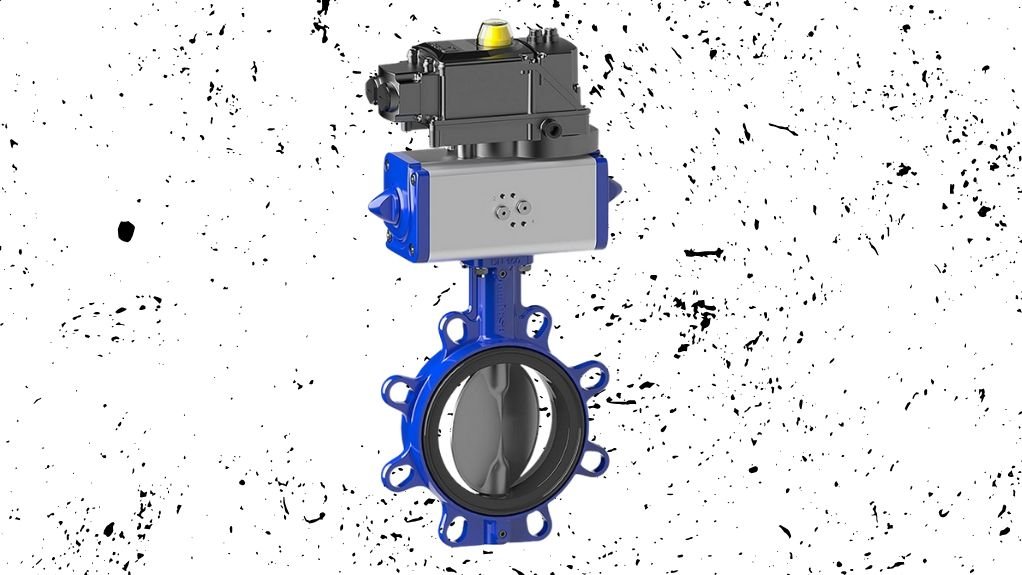

Valves play a critical role across all stages of the mining process, serving to regulate the flow of high-pressure water, corrosive chemicals and abrasive slurries; they are used in various tasks, from minerals extraction to tailings deposition.

However, when valves wear out too quickly or fail under pressure, it can lead to costly repairs, process disruptions and unplanned downtime, he says.

“Mining is a tough environment. Our goal is to build valves that last longer, need less maintenance and help our clients run more efficiently.”

To support this, the company not only assembles off-the-shelf parts but also produces some of its own elastomer components, which are the rubber-like parts that handle internal wear and pressure.

This allows for in-house testing and adjusting of materials based on real mining conditions. For example, KSB’s polyurethane-based elastomers offer greater wear resistance and longer life spans in high-abrasion slurry systems, thereby reducing the frequency of replacing components, Hedges explains.

Valves used in mining must also withstand chemical exposure during processes, such as solvent extraction, where acids and other harsh materials are common.

For these applications, KSB supplies specialised valves lined with polymer or built using specialised materials to suit these environments.

However, Hedges says durability is not enough, noting that more mines are looking for digital solutions to be proactive.

In this regard, KSB has responded with technologies such as its BOA-Tronic valve range which features smart valves that include built-in ultrasonic flow and temperature sensors, allowing for more accurate control and real-time monitoring of conditions inside pipelines.

“Our valves can be linked to telemetry systems, enabling mine operators to monitor performance remotely and carry out predictive maintenance.”

Identifying issues, such as rising temperatures or irregular flow rates, early means mine operators can plan maintenance before a valve fails.

Sustainability

KSB now encourages valve maintenance and refurbishment, rather than full replacement.

As an International Organisation for Standardisation-accredited manufacturer, the company has designed maintenance manuals to help clients continue using the same valve for longer with regular servicing – a practice that not only reduces waste but also helps operations remain cost-effective, over time.

However, when repair or support is needed, Hedges says KSB’s SupremeServe division provides on-site services and original equipment manufacturer-grade refurbishment at its facility in Jet Park, Gauteng.

“With a dedicated parts division, the team ensures that repaired valves meet the same quality standards as new ones.”

By combining in-house technical knowledge with on-the-ground insights, the aim is to develop smarter systems that match specific plant needs while keeping maintenance costs down and performance levels high, Hedges concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation