Specialist laser cladding equipment reduces dust emissions

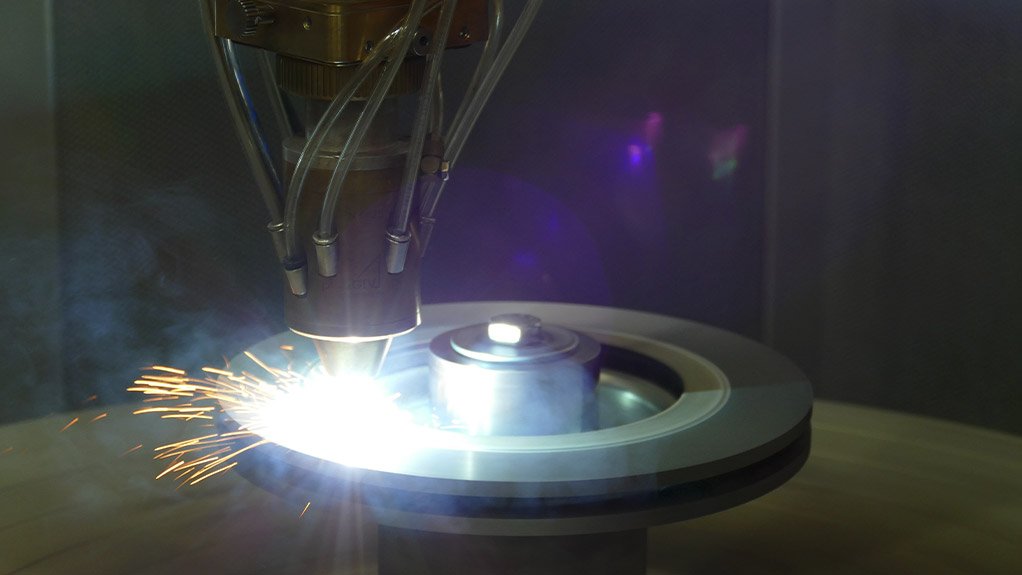

New laser cladding technologies allow for the manufacture of metal components, such as low-wear brake discs, with a significant reduction in fine dust emissions.

The powdered coating material is blown onto the workpiece and then melted by laser, so that it bonds metallurgically with the base material. This method creates more stable protective layers than hard chromium plating and new technologies have increased the process speed and reduced the thickness of the layers, with extremely thin layers of about 80 μm now possible.

Specialist supplier of welding, thermal spray and specialist laser cladding equipment, Weartech, says that the advantages of laser-coated brake discs are corrosion- and abrasion-resistant surfaces, reduced brake dust load and extended service life.

Laser-coated brake discs are not only suitable for current combustion engines, however, they will also be used in future electric vehicles, where brake discs will be required to meet specific standards for low particulate emissions.

Modern lasers can be used for a range of coating applications, including:

- Remanufacturing or repair welding

- Wear and corrosion protection

- Three-dimensional printing, or additive manufacturing

- Surface enhancement

- Coating of boiler tubes

- Coating of components in the oil and gas industry

Weartech offers a variety of products for use in wear, corrosion and hard-facing applications as well as maintenance and fabrication. Weartech recommends products best suited to a customer’s needs and offers in-house and on-site service, training and repairs.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation