Supplier growing tailings product footprint globally

PUMPED FOR SUCCESS Heavy duty slurry pump manufacturer Schurco Slurry continues to develop its footprint in South and Southern Africa

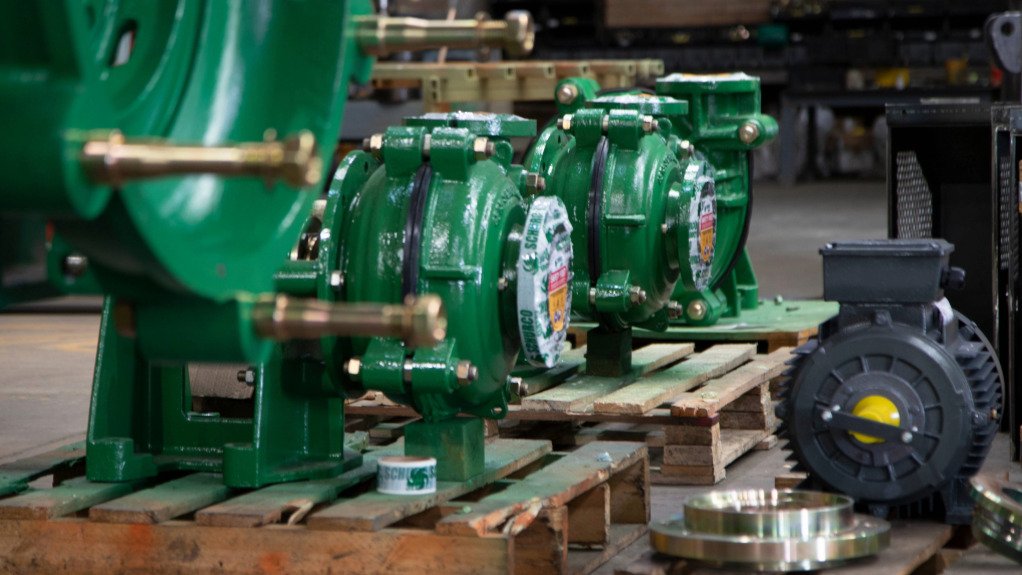

Heavy-duty slurry pump manufacturer Schurco Slurry has developed its presence in South Africa’s tailings transfer/retreatment and storage facilities (TSFs) sector owing to its expert engineering, comprehensive product range and high-quality materials on offer.

The company attributes this uptake to the growing global focus on environmental, health and safety factors in TSF management.

“Schurco Slurry’s internationally trusted offerings ensure that tailings can be transported safely and efficiently to processing and storage facilities,” says Schurco Slurry pump applications and projects manager Marc Young.

This was demonstrated when the company completed the supply of 146 complete pump sets for a major tailings retreatment project located in South Africa, scheduled for commissioning in the coming months.

Young adds that Schurco’s proprietary Ultra-Urethane composite is used in wet-end components for situations involving extreme wear and chemical exposure.

“This material has demonstrated remarkable effectiveness in tailings applications, providing outstanding resistance to abrasion and corrosion in a wide variety of chemical environments.”

In tailings retreatment plants, where pumping distances are shorter, single-stage pumping is generally used.

Young says Schurco’s V-Series pumps, often employed as sump or spillage pumps, play a crucial role in managing excess slurry, as they facilitate the safe and efficient transfer of residual material, consequently helping to maintain a clean operational area and reducing environmental risks associated with pollution or contamination.

Typically, the long-distance pumpstation will comprise multiple pumps in series to meet the flow and total dynamic head required for that particular TSF application.

“Standard configurations may include two to eight or more pumps in series.”

“The first two or three stages are generally equipped with Schurco’s S-Series pumps, followed by high-pressure series pumps ultimately forming a pump train capable of maintaining the flow rate, pressure and velocities required,” explains Young.

The high-pressure units ensure that the system operates within the safe limits of the pump casing’s rated pressure.

Optimal Performance

Young emphasises that key performance metrics for Schurco Slurry’s pumps include a high solids-handling capacity and a long wear life of components in abrasive conditions.

“Efficiency in handling viscous and high-density slurries, as well as a robust hydraulic design, ensures a stable flow and that pressure is maintained throughout the operation.”

These pumps are built to meet or exceed industry benchmarks for uptime, reliability and total cost of ownership, he adds.

Since the resulting slurry from the extraction process typically contains fine particles that are excessively abrasive and, in many cases corrosive – owing to the reagents used during extraction, reliable materials that offer excellent abrasion and corrosion resistance must be used in the pump assemblies.

Tailings slurry is often transported over long distances of several kilometres to designated storage facilities, which necessitates that the pumps must be robust enough to carry the load and pressure required.

“This is where Schurco Slurry’s expertise becomes a key advantage,” enthuses Young.

The Schurco team ensures the correct selection of pumps and materials tailored to the specific requirements of every TSF application.

As such, in the spillage areas on site, the company’s vertical slurry pumps eliminate the need for submerged bearings, shaft seals or sealing water systems, which are common failure points in conventional designs.

This simplification significantly reduces maintenance requirements, avoids costly shutdowns and lowers operational costs.

“Maintenance tasks are streamlined, thanks to modular designs and easily replaceable wear components, ensuring that pumps stay in service longer, with minimal intervention,” he adds.

Another key element is maintaining steady and stable feed into the pump suction through engineered system design, which affects efficient operation and prevents cavitation and premature wear or failures.

“Schurco recommends system designs that minimise turbulence, vortexing and sediment accumulation,” he avers, adding that adequate or stable slurry feed, strategic system design and consistent flow control, are key elements in this regard.

The company also offers engineering guidance to customers to optimise sump, tank and piping design for optimum pump performance and service life.

With a focus on service, support and responsiveness, Schurco helps customers increase the life and efficiency of their pump systems in the harshest tailings and mining applications, states Young.

“The company backs every pump and part supplied with a commitment to customer success, ensuring reliable performance and reduced life-cycle costs,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation