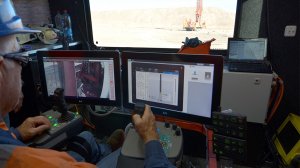

Surface drills with automation functionality

Mine automation is being extended for use on surface drill rigs, helping to improve safety and productivity.

Sandvik Mining and Rock Solutions’ AutoMine functionality is available for its i-Series models in the company’s intelligent range of down-the-hole top hammer and rotary blast hole drill rigs.

“Sandvik AutoMine system essentially replicates the machine control system to enable remote automation over the mine’s Wi-Fi network,” says Sandvik Southern Africa business line manager: automation and digitisation Kabelo Nkoana. “There is an awareness that safety could be compromised when rigs are operating close to a highwall, or when there are unstable geological conditions on the bench. Automating a drill rig in these conditions is an important contributor to safety.”

The i-Series machines include features such as the onboard data collection unit technology for engine operation and other major components. Various operational and machine health data from the sensors are collected in the Knowledge Box and transmitted to cloud storage for analysis and real-time reporting to support informed and accurate decision making. This creates the foundation for the automation process, which also enhances reliability and performance.

Nkoana explains that the machines’ extensive sensing capability enables it to pick up valuable data about its working environment and allows it to operate autonomously within its design limits.

“This means that it will respond quickly to changes in its drilling conditions – in the properties of the rock it is drilling, for instance,” he says. “By not exceeding its limitations, its operating behaviour will extend the life of consumables and components, generally leading to a lower total operational cost.”

The company is also incorporating artificial intelligence (AI) into its next generation AutoMine system solutions, with the launch of its concept loader and underground drill. The AI system uses perception-sensing technologies to detect obstacles, and can make decisions about its movements when there is a person or other manual equipment in proximity.

Nkoana highlights that mines in southern Africa are gradually moving toward ‘smart mining’ through digital monitoring and control, as well as automation.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation