The environmental and practical benefits of using fibre in concrete

Michelle Fick, BU Development Manager : Concrete Aesthectics at CHRYSO Southern Africa

Using fibre in construction helps companies reduce carbon emissions, minimise energy consumption and cut waste, significantly lowering their environmental impact

Fibre-reinforced concrete minimises labour, time and waste, resulting in long-term savings for infrastructure projects

Embracing innovative materials like fibre is key to a sustainable construction sector, aligning with global environmental goals and positioning companies at the forefront of eco-friendly practices

Fibre in concrete is transforming the construction industry, providing contractors with a sustainable and efficient alternative to traditional steel reinforcement

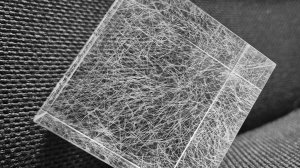

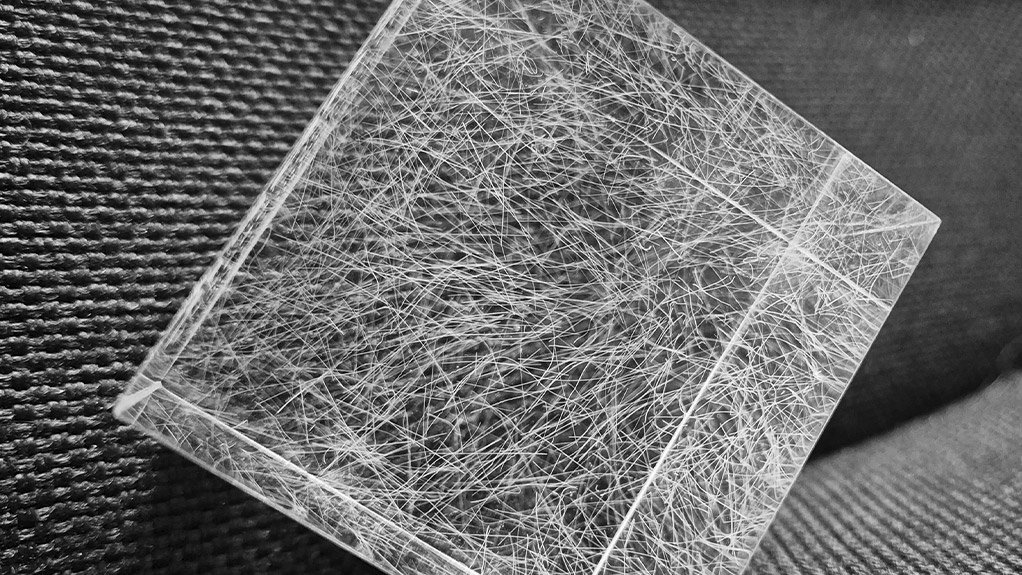

Synthetic microfibre for concrete

This article has been supplied.

In today's construction industry, the twin imperatives of sustainability and efficiency are driving transformative innovations. One such advancement making waves is the use of fibre in concrete, replacing traditional steel reinforcement. This shift not only results in substantial time and labour savings leading to significant cost efficiencies, but also plays a pivotal role in reducing the carbon footprint associated with construction projects.

Steel reinforcement, while indispensable for its strength and durability, exacts a heavy toll on the environment. The production of steel involves substantial energy consumption and emits significant amounts of carbon dioxide (CO2). According to the World Steel Association, the steel industry accounts for approximately 8% of global CO2 emissions, making it a prominent contributor to climate change.

Michelle Fick, BU Development Manager: Concrete Aesthetics at CHRYSO Southern Africa, says that fibres, in contrast, are made from synthetic and natural materials and offer a far more sustainable alternative. Concrete containing fibres is thus easily recycled for reuse as crushed aggregates for other projects.

The environmental benefits of this shift are significant. The production of fibre materials, particularly synthetic ones, generates considerably less CO2 compared to steel production. Additionally, the energy requirements for manufacturing fibres are significantly lower.

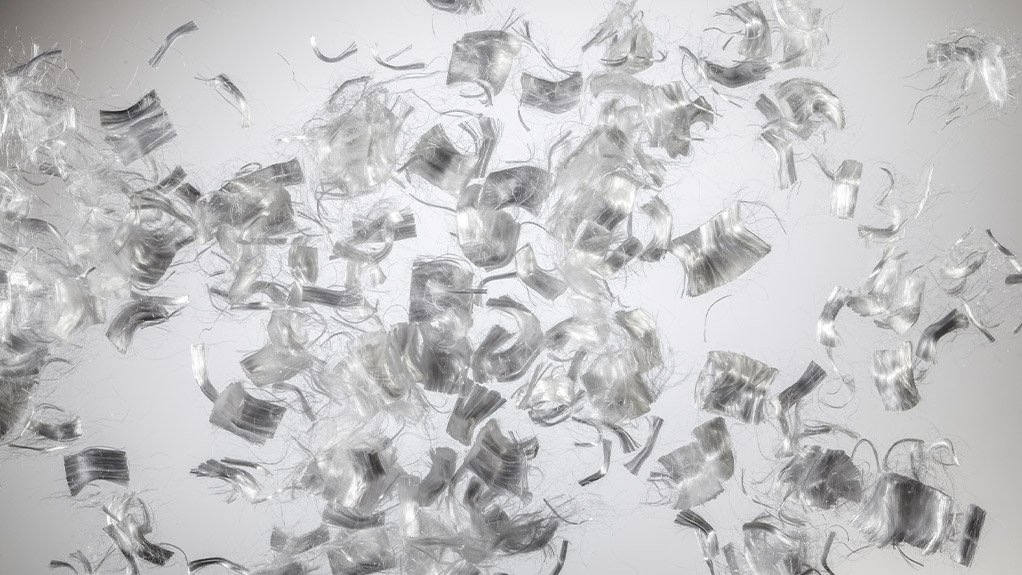

“By substituting steel with fibres, construction companies can markedly decrease their carbon emissions,” Fick says. “Further unlike steel reinforcement, which often involves cutting and fitting, leading to substantial scrap material which needs to be managed, our Advil fibres can be precisely mixed into concrete, minimising waste on construction sites. This reduction in waste contributes further to the sustainability credentials of fibre-reinforced concrete.”

Beyond the environmental advantages, fibre reinforced concrete offers several practical benefits that enhance construction efficiency. Integrating fibres into concrete is straightforward and can be done during mixing, eliminating the labour-intensive steps of placing and tying steel reinforcement.

This streamlined process significantly accelerates construction timelines. The simplicity of using fibres reduces the need for specialised labour typically required for handling and installing steel reinforcement. This not only cuts down on labour costs but also mitigates the risk of on-site injuries associated with traditional steel handling.

Fick says that while the initial cost of fibres may be close to that of traditional steel reinforcement, the overall savings in labour, time and reduced waste translate into lower total project costs over the lifecycle of the construction project.

Fibre-reinforced concrete has been successfully deployed in numerous projects globally as well as locally, highlighting both its practical and environmental benefits. Infrastructure projects like roadways and bridges have reported enhanced durability and reduced maintenance costs due to the use of fibres.

Moreover, residential and commercial buildings have benefited from faster construction times and improved structural performance, highlighting the versatility and effectiveness of fibre-reinforced concrete across diverse applications.

Available from CHRYSO, Adfil’s range of high quality fibre reinforcement solutions are designed to enhance the performance of concrete by improving its durability, reducing cracking and increasing its structural integrity. By integrating Adfil fibres into concrete, construction projects can achieve superior results while also benefiting from the environmental advantages of reduced carbon emissions and lower energy consumption.

Adfil offers a range of fibres tailored to various construction needs including macro-synthetic fibres, micro-synthetic fibres and steel fibres. These products are engineered to provide optimal reinforcement, ensuring that concrete structures can withstand the demands of modern construction without the drawbacks associated with traditional steel reinforcement.

“We believe that the adoption of fibre in concrete represents a paradigm shift in the construction industry, and offers contractors a sustainable and efficient alternative to traditional steel reinforcement,” Fick says. “By reducing carbon emissions, minimising energy consumption and cutting down on waste, construction companies can significantly lessen their environmental impact while bolstering their operational efficiencies.”

“As the construction sector continues to prioritise sustainability, embracing innovative materials like fibre will be pivotal in fostering a greener future. These advancements not only align with global environmental goals but also position construction companies at the forefront of sustainable practices, driving both environmental stewardship and economic viability,” Fick concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation