Vehicle manufacturing plant gets advanced drive tech

State-of-the-art decentralised drive technology is being incorporated into a new storage and retrieval system at a US-based vehicle manufacturing facility. The technology from SEW-EURODRIVE’s Generation C range will help streamline the supply of vehicle bodies to the existing manufacturing unit, to meet the rising demand for vehicles and to improve production capacity.

Highlighting the significance of securing the order, SEW-EURODRIVE South Africa Gqeberha branch manager Phillip Steyn says the company has a solid track record in supplying drive technology solutions to the automotive industry.

Steyn points out the strong global support network of the automation company offers logistical flexibility and optimal shipping strategies, including some drives being shipped directly from Germany to the US, while others are directed to the company’s facility in Gqeberha.

"We have strategically planned our deliveries in phases, tailored to the project’s requirements. Project completion is scheduled for September 2024," adds Steyn.

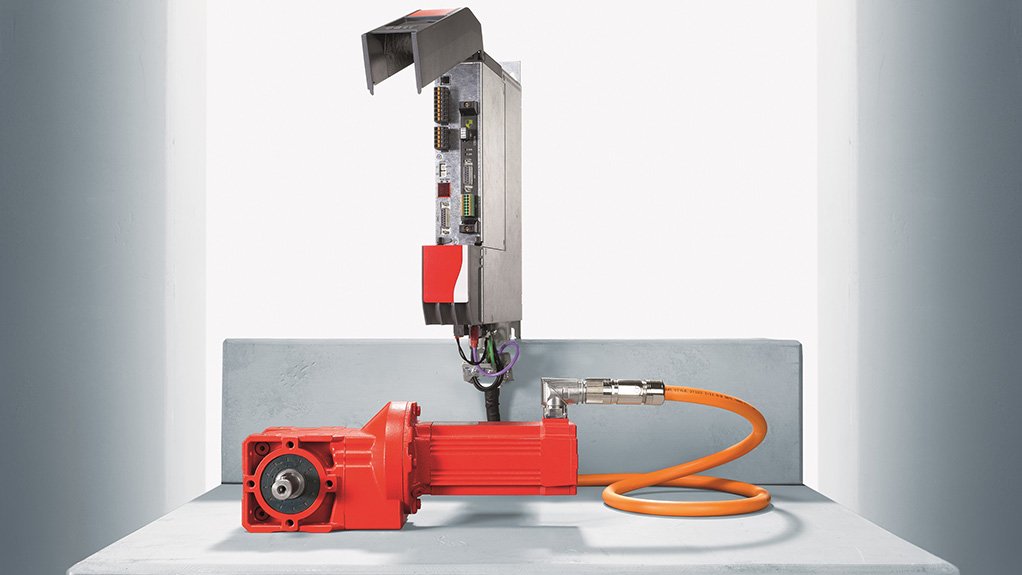

“It's noteworthy that this particular vehicle manufacturer relies consistently on SEW-EURODRIVE's drive technology for all its global facilities. Specifically for this project, over 300 units from the Generation C range will be incorporated and this decentralised technology will facilitate independent and collaborative operations of the drives, either positioned on or near the motor in the field,” he explains.

The decentralised drives will be integrated with the company’s digital data interface platform and servo technology designed for peak energy efficiency.

Steyn elaborates on the advantages of decentralised tech over its centralised counterpart, underscoring its sustainability and consistency. "All products in our decentralised range share a uniform controller and interface, enhancing user experience and flexibility, with reduced spare parts inventory."

The incorporation of the technology will help to ensure quicker and cost-effective installations, faster maintenance response times and minimal disruptions, enabling uninterrupted productivity.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation