Vesconite Hilube revolutionises pump performance on the Gulf Coast

Vesconite Hilube line shaft bushings have proven successful in seawater lift pumps and oil waste-disposal pumps on the Gulf Coast

This article has been supplied.

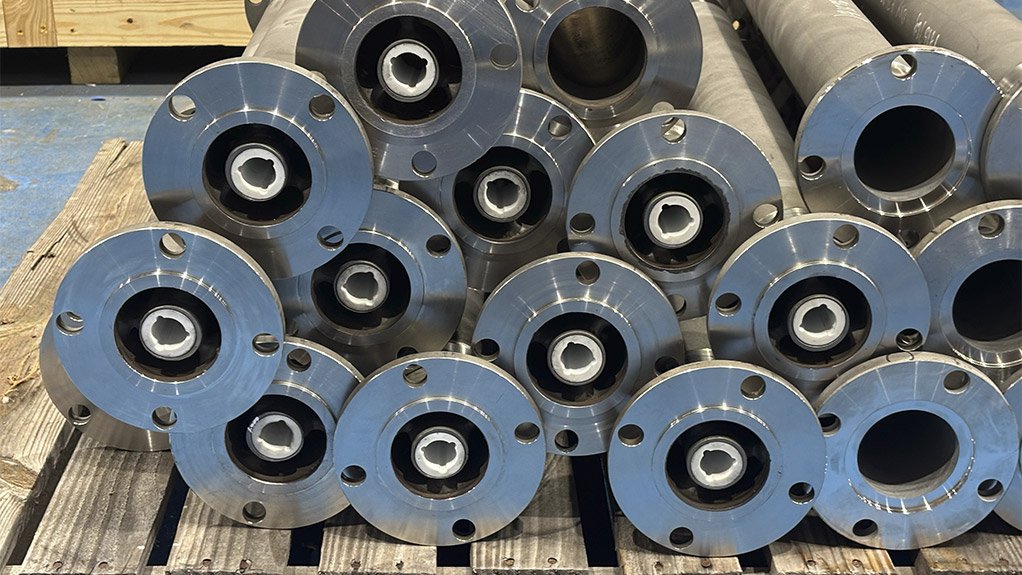

One of Vesconite Bearings’ innovative bushing materials, Vesconite Hilube, has assisted a US pump manufacturing company on the Gulf Coast in coping with its harsh and highly corrosive operating environments, which pose significant challenges for pump systems.

Before switching to Vesconite Hilube line shaft bushings, the pumps relied on materials like bronze, cutlass rubber, and 316 stainless steel. While these materials were reliable to some extent, they struggled to endure the demanding conditions encountered by seawater lift pumps and oil waste-disposal pumps. They were operating at ambient temperatures of up to 120°F (49°C), with a flow driven by 1,800 RPM, and these pumps handled ocean saltwater mixed with fine abrasive particles—a punishing environment for any material.

“We were looking for a bushing or wear material that could stand the test of time in highly corrosive conditions, and Vesconite Hilube significantly increased run time and lengthened the time between repairs,” says the operations manager at the US pump manufacturing company.

He adds that compared with traditional materials, Vesconite Hilube consistently delivered superior durability and performance, noting that it has become a go-to material for various services along the Gulf Coast, particularly in vertical seawater lift pumps and oil waste-disposal pumps.

“Vesconite Bearings makes my job easy,” says the operations manager. “Its customer service is second to none, and it stands behind its products and services. Being able to source and procure this material easily has greatly increased our credibility and trust between our company and customers.”

With Vesconite Hilube continuing to prove its worth, the future looks bright for its adoption in even more applications. “Absolutely,” the operations manager says when asked if the company foresees further developments with the material. “The trust and reliability built between Vesconite Bearings and its customers are set to drive even greater success.”

The pumps, operating in some of the most demanding conditions on the Gulf Coast, exemplify Vesconite Hilube’s ability to overcome the limitations of traditional materials. As the industry continues to evolve, Vesconite Bearings stands as a testament to innovation and dependability, delivering solutions that meet and exceed expectations.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation