Vibrating-equipment supplier cites stable demand from food sector

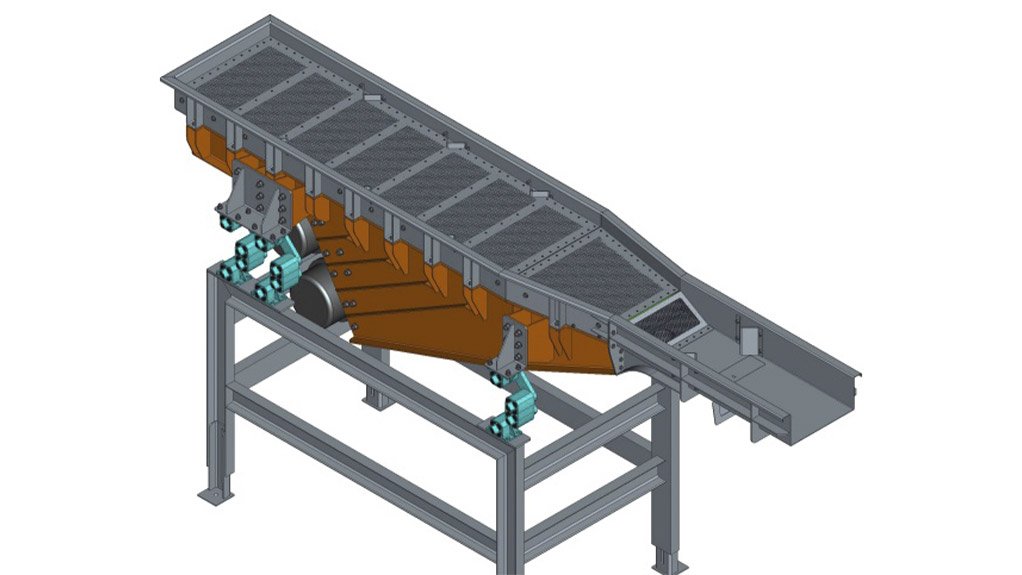

GOOD VIBRATIONS Vipro is continuously supplying clients in the food industry with electromagnetic drives, electromechanical drives and vibrating equipment

The food industry’s demand for the equipment and services of vibration-equipment manufacturer Vipro Vibrating Products is stable, with the industry focused on maintaining its existing equipment to achieve the longest possible operating life.

“Demand is neither at an all-time high, as we are not working on any new projects, nor is it the lowest it has ever been, as we are still receiving orders from our existing client base and consultants to the industry,” says Vipro international sales and marketing manager Pieter Uys, noting that the food industry makes up a notable percentage of the company’s business.

He explains that the food industry consists of a series of industrial activities like processing, conversion, preparation, preservation and packaging. There are also multiple role-players in manufacturing the food South Africans consume, ranging from small, traditional, family-run activities, to large highly mechanised industrial processes.

The food industry relies heavily on vibration to convey products from one point to another during the manufacturing process for sizing, separation, dewatering and packaging. Therefore, Uys says, each motor, feeder or screen sold by Vipro is of critical importance to the end-user.

Factories cannot afford production lines to be shut down, as they have to continue operating to produce certain targets. Accordingly, there will always be a need for replacement parts and the maintenance of vibrating equipment.

Most of Vipro’s work in the food industry involves existing clients, which include producers of animal feed, cereals, chips, meat and sugar, all based across South Africa, with which Vipro has enduring relationships and which are, subsequently, familiar with its offering.

“Our clients range from chemical suppliers, agricultural businesses, food processors and weighing and packaging suppliers. With our face-to-face approach, we also service both the smaller manufacturing companies as well as the large major industry role-players,” Uys explains.

The company offers its clients high-quality, original-equipment manufacturer specified spare parts on all its equipment to increase the life span of the units and prolong the replacement of units where possible, he notes.

Vipro continuously supplies clients in the food industry with electromagnetic drives, electromechanical drives and vibrating equipment.

“Most of our sales in the food industry are generated from our Venanzetti motors. These motors are popular in the industry and come with a 12-month guarantee,” says Uys.

The Venanzetti motor offers continuous operation up to 100% centrifugal force through use of special execution heavy-duty bearings, with Vipro using only SKF, FAG and NSK bearings during the manufacture or repair of its motors.

The motors are also equipped with a special device and weight regulation system with a calibrated indicator indicating centrifugal force, resulting in the significant reduction of problems associated with incorrect weight settings.

Further, Venanzetti motors offer reduced maintenance, with lubrication intervals of up to 5 000 hours, owing to the use of long-life barium-based lubricants. AISI 304 stainless steel weight covers are available across the range, providing not only superior corrosion protection but also significantly reducing moisture penetration and the associated electrical failures.

While these stainless steel covers are more hygienic than normal mild steel painted end-caps, Venanzetti motors are also dust and water jet proof with a standard mechanical protection rating of IP66.

The motors, comprising hard-wearing surfaces with standard painting of 120 μm thick using epoxy powder that is polymerised at 200 ºC, also offer end-users a higher level of reliability through the impregnation of the stator with the vacuum system – up to size GA included – or the trickle system.

“Our expertise in the food industry is not just limited to our vibrating equipment and motors but also includes flow simulation software. In an industry where capital for new projects is not readily available, clients are constantly looking for innovative ways to improve and prolong the life span of the process equipment already in use.”

Vipro’s engineers use flow simulation software to increase the efficiency and service life of existing equipment with minimum disturbance or modification. This software can also be used for wear detection on machinery to ensure minimum wear rates and, subsequently, increase life span and reduce maintenance.

“We invest heavily in understanding the specific needs of each of our customers. It is this attitude that keeps us relevant in the ever-changing environment that is the food industry,” concludes Uys.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation