WearCheck Technical Bulletin: CRUDE AWAKENING Part 2

This article has been supplied.

By: Rivendren Wayne Moodley – diagnostician, WearCheck

(Virtual Showroom) In a world constantly in motion, where ambition shapes empires and innovation fuels the future, there exists a silent force, unseen yet omnipresent. It threads through industries, binds economies, and lingers beneath every moment of modern life. It does not demand attention; rather, it works quietly, whispering beneath the hum of progress, woven seamlessly into the very foundation of civilisation.

For generations, humanity has relied upon this force, stretching it to its limits, building entire industries upon its strength. It empowers nations, accelerates technological breakthroughs, and dictates the rhythm of history itself. And yet, despite its immeasurable influence, it remains overlooked, hidden in plain sight. What is this invisible force, this mysterious driver of the modern world?

It is crude oil – it flows beneath our feet like a buried promise, drawn up to ignite the engines of an entire era. It pulses through pipelines and pistons, stitching together continents with asphalt and steel. From the spark of a factory floor to the flight of a jetliner, it powers ambition, carves out empires, and lifts civilisation onto a new axis. Every machine, every city street, every glow of neon owes something to its dark and potent charge. It is not just energy- it is the silent architect of modern life.

A DAY ENVELOPED IN OIL’S INFLUENCE

An alarm pierces the stillness of early morning, dragging you abruptly from sleep. Instinctively, your hand reaches for your phone. This device, indispensable in modern life, connects you instantly to messages, updates, and work responsibilities. Its plastic casing, a direct result of petroleum’s versatility, encapsulates a screen coated with oil- derived compounds.

You swing your legs off the bed. The mattress shifting beneath you is made with foam layers formed from polyurethane, a synthetic polymer derived from petrochemical feedstocks. Even the pyjamas you wear contain a blend of cotton and polyester, each thread a fusion of natural fibre and petroleum-based elasticity. As you stand, the fibres in the carpet warm your feet and the drapes hanging at the window catch the morning light, both designed using oil-based materials that have quietly embedded themselves into the domestic sphere.

In the bathroom, a single flick of a switch floods the space with electric light. That current runs through cables insulated with compounds refined from oil, forming a grid of energy transmission that supports every aspect of daily activity. When you apply toothpaste to your toothbrush, the smooth texture and consistent form of the paste are made possible by stabilising agents derived from petroleum-based chemicals. The toothbrush itself is manufactured using crude oil derivatives, including durable thermoplastics for the handle and resilient nylon fibres for the bristles, ensuring structural integrity and effective cleaning performance. Shampoo lathers under the water, producing rich foam, while beauty creams glide across your skin, formulated to nourish and protect with ingredients linked directly to oil processing. The scent of deodorant follows as you finish your routine, another quiet contribution from petrochemical innovation.

Later, as you fasten your trainers and feel the resilience of their soles beneath your feet, you are walking on yet another product of crude oil. Their structure relies on flexible materials extracted and refined from heavier oil components, designed to endure impact and movement.

In the kitchen, the scent of coffee drifts through the air as you open the smooth plastic cereal packaging, a material engineered for freshness and flexibility through refined petrochemical processes. The cup you take with you, lidded and insulated, is a blend of convenience and chemistry made possible by oil’s transformations. Even the sweetener that dissolves in your drink carries compounds born in industrial reactors rather than sugarcane fields.

Outside, the morning air holds a chill and beneath your feet the tarred surface of the road stretches ahead, hardened by bitumen that binds rock into roads. The car door clicks open, and you lower yourself into synthetic leather seats, cool and firm, shaped through petroleum polymers. The ignition sparks the engine to life, announcing oil’s most visible role as fuel. Yet around you, oil’s quieter work surrounds your commute—the dashboard moulded from resilient plastics, the electrical wiring encased in protective oil-based compounds, the tyres gripping the asphalt with strength drawn from processed rubber.

In the office, the day begins as you settle into a chair cushioned by flexible foam derived from petroleum. Your fingers move across a keyboard; its keys shaped from high-density polymers designed for durability. The printer nearby hums and releases pages, inked with formulations that owe stability and adhesion to refined oil derivatives. A constant ambient temperature is maintained by a climate-control system dependent on oil-based coolants flowing through sealed circuits.

Your computer powers on, its heart a microchip etched from silicon and layered with patterns formed through petrochemical engineering. From solvents that clean its delicate pathways to binding agents in the circuit boards, oil is present in every function and frame. Each chip is an intricate artefact layered with the energy history of the petroleum age, evidence that oil does not merely fuel but fabricates the modern world.

Lunch arrives in containers that gleam beneath fluorescent lights, shaped from thin films designed to preserve flavour and extend shelf life. Preservatives in dressings and protective coatings on produce are crafted from chemical pathways sourced from petroleum, making distant harvests accessible across seasons. At the gym, polyester fabric clings and stretches with ease, its threads spun from synthetic fibres engineered to move and breathe.

Equipment hums smoothly, each motion supported by oil-based lubricants applied to rotating components. From treadmill belts to barbell grips, every material has been engineered for consistency, performance, and safety, all made possible through industrial chemistry rooted in petroleum.

Evening brings rest. At home, you collapse onto a couch upholstered in resilient synthetic fibres. The television casts vivid images across the room, its crisp display the result of oil-based optical coatings and insulated internal components. A book in your lap feels familiar, its spine bound with oil-derived adhesives and printed with pigment stabilised through petroleum agents. The day winds down with a hot meal prepared in a non-stick pan crafted from polymer science, its surface engineered to resist heat and residue. A glass of wine, filtered and preserved using refined oil compounds, complements the simplicity. Afterwards, a soft towel wraps around you, its threads strong and smooth. Moisturiser glides over your skin, rich in texture and preservation thanks to petrolatum. As you ease into sleep, the day recedes, shaped entirely by a substance drawn from beneath the earth yet present in every aspect around you.

From the warmth of breakfast to the final light fading at night, petroleum remains a constant, though often unnoticed, companion.

OIL’S BROADER CANVAS

Oil isn’t just fuel; it’s the architect of modern life, crafting the tools, comforts, and connections on which we lean.

In 2024, the world burnt through 104 million barrels daily, not just powering cars but producing 110 million metric tonnes of polyethylene, the plastic that wraps food and builds homes. Asphalt, oil’s heavy child, lays down 1.5 billion tonnes of road surface—binding towns and cities in a web of engineered pathways. Synthetic fibres, born from oil, weave 60% of global clothing, from your shirt to your trainers.

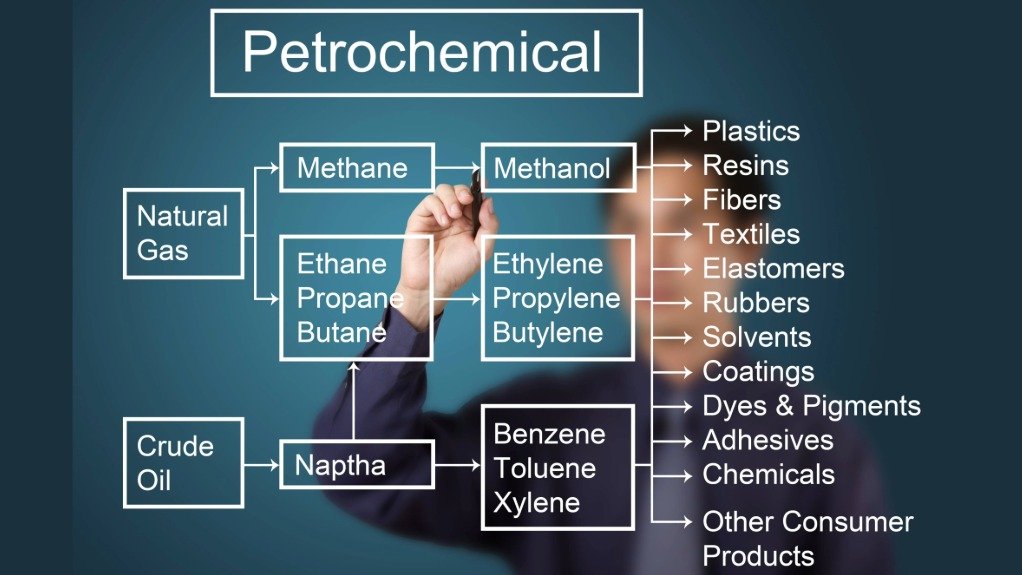

THE CHEMISTRY POWERING THE MODERN WORLD

Crude oil serves as a foundational input in the global industrial economy. Its transformation into thousands of chemical products occurs through complex thermochemical and catalytic refining pathways. In 2022, global investment in refining and petrochemical infrastructure exceeded 4.5 trillion Rand, with significant capital allocated to oil refineries and specialised petrochemical plants. These facilities enable the repurposing of hydrocarbons into functional materials across sectors such as construction, medicine, consumer goods, and electronics.

PLASTICS AND INDUSTRIAL POLYMERS

At the core of petrochemical processing are fluid catalytic cracking units, where crude fractions are heated to between 480 and 550 °C. In the presence of zeolite-based catalysts, long hydrocarbon chains are cracked into smaller olefin compounds such as ethylene and propylene. These light olefins are the precursors to global plastic production, which exceeds 400 million metric tonnes annually.

Ethylene is polymerised in pressurised reactors using specialised catalysts to produce polyethylene. Variants such as low-density polyethylene and high-density polyethylene are manufactured for diverse applications, including plastic bags, agricultural films, piping, and injection-moulded automotive components. Polyethylene accounts for nearly 30% of total global plastic output.

Steam cracking furnaces operate at 800 to 900°C to generate high-purity ethylene and propylene from naphtha and ethane. These feedstocks support the production of polypropylene, widely used in food packaging, fibre production, and automotive mouldings. The polypropylene market alone exceeds 80 million metric tonnes per annum, with production values estimated at over 120 billion US dollars globally.

SYNTHETIC FIBRES AND TEXTILE APPLICATIONS

The textile industry is extensively dependent on petroleum-based intermediates. Catalytic reforming of naphtha generates benzene, toluene, and xylene. Paraxylene is oxidised to form purified terephthalic acid, which is combined with ethylene glycol to produce polyethylene terephthalate at processing temperatures of 260°C. The resulting polyester fibres represent the majority of global textile production, providing durable and stretch-resistant materials for clothing, upholstery, and industrial fabrics.

Additional polymers such as nylon are synthesised from adipic acid and hexamethylenediamine, both derived from petroleum intermediates. Nylon fibres are used in ropes, parachutes, and carpets. Acrylic fibres are manufactured from acrylonitrile, obtained via the ammoxidation of propylene. These fibres are commonly used in outdoor apparel and high-performance garments. Collectively, petroleum-based synthetic fibres comprise over 60% of the global clothing market.

LUBRICANTS AND FUNCTIONAL FLUIDS

High-boiling-point fractions of crude oil, such as heavy gas oils, are further upgraded through hydrocracking, a catalytic process that thermally and chemically breaks down large hydrocarbon molecules into smaller, more valuable products. The reaction occurs in the presence of hydrogen and specialised catalysts, typically under high pressures of 80 to 120 bar and elevated temperatures. Hydrogen facilitates the breakdown while saturating the resulting hydrocarbon chains, yielding cleaner, more stable outputs such as diesel, jet fuel, and base oils. The resulting base oils exhibit uniform molecular weight distributions and high stability, making them ideal for use in engine lubricants, transmission fluids and hydraulic oils.

The global lubricants industry processes over 40 million metric tonnes of base stock annually, with petroleum-derived oils accounting for more than 90% of the market. These products enable friction reduction, thermal stability, and mechanical efficiency in vehicles, industrial machinery, and power-generation equipment.

PHARMACEUTICALS AND PERSONAL CARE PRODUCTS

Vacuum distillation of petroleum residues yields highly refined mineral oils used in dermatological and cosmetic formulations. Dewaxed petrolatum is used in ointments and wound-care products due to its emollient and occlusive properties.

Pharmaceutical-grade paraffin and microcrystalline waxes, also derived from vacuum distillates, are employed as stabilisers, bulking agents, and controlled-release vehicles in solid-dosage forms.

Propylene glycol, synthesised via the hydration of propylene, aids in moisturising and acts as a solvent in topical creams, oral medications, and injectable drugs. Many over-the-counter preparations, including topical antibiotics, emollients, and nasal sprays, utilise these intermediates. The pharmaceutical market linked to petroleum derivatives is estimated at over 25 billion US dollars globally.

PACKAGING AND FOOD PRESERVATION

Plastic packaging represents one of the highest-volume applications of crude derivatives. Linear, low-density polyethylene, branched polypropylene, and polyethylene terephthalate films are all produced from petroleum monomers. These materials offer moisture resistance, mechanical strength, and thermal sealing properties.

Food preservatives such as butylated hydroxyanisole and butylated hydroxytoluene are synthesised using petroleum- derived precursors. These antioxidants extend shelf life by inhibiting oxidative degradation. Non-stick coatings for cookware, primarily based on polytetrafluoroethylene, are manufactured using fluorinated hydrocarbons processed from petroleum.

INFRASTRUCTURE, ELECTRONICS, AND HIGH-TECHNOLOGY MANUFACTURING

Bitumen, produced from the vacuum bottom residue of heavy crude, is used to pave over 100 million metric tonnes of road surface annually worldwide, linking cities and countries spanning millions of kilometres. Bitumen binds aggregate materials in asphalt mixtures, providing durability, water resistance, and load-bearing performance for highways and urban infrastructure.

Synthetic rubber compounds are formulated from butadiene and styrene; both derived from ethylene steam- cracking processes. These elastomers are essential to tyre manufacturing, sealants, belts, and vibration isolation systems.

In the electronics industry, high-purity petroleum solvents such as xylene and isopropanol are used in the photolithography and cleaning stages of semiconductor fabrication. Silicon wafers are etched, cleaned, and coated using chemical streams that originate from refined hydrocarbons. Printed circuit boards, microchips, and display screens rely heavily on compounds and substrates derived from crude oil.

From the ignition of morning routines to the quiet dimming of nightfall, petroleum remains a vital yet often unseen pillar of modern life. Its influence stretches far beyond fuel and manufacturing. Silently enabling the movement, promotion, and sale of countless goods and services. Even when crude oil is not a direct input, its presence underpins the infrastructure, logistics, and commercial systems that deliver and sustain them. Threaded into the very architecture of progress, it flows through the arteries of society with quiet indispensability and a profound reach.

What happens when this fragile lifeline frays? When reserves dwindle, when dependency exceeds reserves and the foundation beneath our modern world begins to crumble?

Would civilisation prevail? or would its delicate weave unravel? Could human ingenuity overcome its absence, or would the great engines of progress stall, plunging the world into chaos? As uncertainty looms and our grip weakens, one question remains, have we relied on it for too long? And if this thread finally snaps, will we survive the collapse? Let us look into one potential future timeline that awaits us.

SLOW COLLAPSE – DRYING UP OIL

No cataclysm marks oil’s end, no blazing apocalypse or sudden fall. It creeps, a silent reaper, dismantling the world until civilisation’s heartbeat fades. In 2024, 1.7 trillion barrels of proven reserves remained. With a current usage of 104 million barrels daily in 2025 and increasing, these reserves are diminishing fast. Rig workers hear it in stuttering pumps, analysts see it in falling yields, and policymakers hide it in hushed rooms, their promises dust against the truth: oil is slipping away.

THE FIRST PHASE: THE COST OF SURVIVAL

It starts as a whisper, a tremor in the system. By 2040, petrol surges past R150 a litre, then R300, climbing ever higher, its relentless ascent blamed on market forces. But this is no fluctuation of chance; it is scarcity tightening its grip. Wells run dry, and crude extraction becomes a brutal contest against nature. Steam injection and chemical flooding, desperate measures meant to squeeze out every last drop, yield only marginal gains of 5 to 15% more oil, each barrel demanding nearly as much energy to extract as it provides. Fuelled more by memory than oil, the refinery begins to choke on its own fumes.

Drillers scour forgotten fields, their machines clawing at barren stone, searching for remnants where rivers of oil once flowed. The lifeblood of industry is fading, and the world is beginning to feel the strain.

THE SECOND PHASE: THE DOWNWARD SPIRAL

Life holds to routine for a moment. Planes soar, engines purr, shelves stay stocked. But cracks spread beneath. By 2050, shipping stumbles, fuel shortages stranding freighters mid-sea, hulls rusting under the pitiless sun. Factories crafting plastics, glues, and lubricants halt, their petrochemical veins begin to run dry. Petrol stations ration fuel, prices crushing hope, and a truck driver, once road’s master, siphons petrol into jars, guarding it like a relic. Politicians tout electric grids and biofuels, but engineers, hunched over fading screens, know the maths: civilisation’s foundations are crumbling.

THE THIRD PHASE: THE UNRAVELLING OF INDUSTRY

By 2060, industries collapse, their pulse gone. Polyethylene, nylon, PVC, pillars of packaging, textiles and buildings fade as petrochemical plants go dark. Once producing 400 million tonnes of plastic yearly, 70% derived from oil, these factories now stand cold, pipes silent. Semiconductor plants, reliant on oil solvents for microchips, stop, starving supplies for phones, robotics and factories. A technician, alone in a dead cleanroom, watches monitors die and instruments lying useless without the chips that once drove them.

Food packaging fails without oil-based films and stabilisers. Fruit and vegetables rot in crates, bread moulds in hours, shelves lie empty. Fertilisers, 70% from oil-derived ammonia via the Haber-Bosch process, vanish, fields withering and yields crashing.

Farmers, hands cracked from toil, stare at stunted wheat whilst their children’s hunger becomes a growing weight. Pharmaceuticals falter, oil-based carriers are gone, hospitals ration antibiotics, medication. A doctor, turning away a fevered child, feels her own heart break, her hands empty of cures.

Alternatives betray their hope. Electric engines seize without oil lubricants, bearings grinding to dust. Solar panels and turbines, tied to oil-based polymers, decay, their power only providing a sliver of oil’s 31% global share. Cities contract, buses stall, trains rust. Trade dies, cargo ships rot in ports, their last voyages becoming campfire tales.

Families flee urban graves, trudging to rural patches, chasing survival over ambition. The world starts to shrink, its threads snapping, a tapestry in tatters.

THE FOURTH STAGE: GLOBAL FRACTURE AND CONFLICT

Scarcity births betrayal. Nations with oil, their wells trickling, hoard every drop, sealing exports. Petrostates, once partners, wield barrels as weapons, demanding land, water and submission. By 2070, alliances burn, armies swarming dying rigs, tanks guzzling the fuel they guard. A soldier, atop a desert pipeline, sees it shimmer under moonlight, each litre a fading spark of power.

Economies implode, inflation spirals and banking collapses, rations replacing rand, fuel coupons worth more than gold. Cities erupt, crowds storming tankers, screams lost in gunfire. Coastal towns, once trade hubs, are reduced to empty harbours, merchants staring at bare shelves, dreams of goods, dead. Violence spreads, not for ideals but survival. Borders bleed, oil-less nations clawing at those with scraps. Governments ban cars, ground planes, ration fuel for farms, while grids flicker, oil-built wires failing. An engineer, patching a dying transformer, knows that darkness waits, each fix a fleeting stay.

THE FINAL PHASE: A WORLD WITHOUT OIL

The final barrel is gone. Across continents, engines fall silent. Pipelines run dry. Cities once ablaze with energy now echo with the collapse of their foundations. Without petroleum, the earth stands hollow, resonating with the decay of a vanished industrial age. Global society, built on the combustion and conversion of crude oil, has entered terminal decline.

Factories have rusted into silence. Conveyor belts remain frozen, their lubricants long exhausted. Gears remain locked, corroded, their intricate designs rendered useless. A scavenger in the debris of a plastics plant tries to resuscitate lost miracles, melting remnants in rusted crucibles, but efforts yield nothing but waste. The industrial engine of civilisation has become a static graveyard; its wealth reduced to dust drifting through collapsing rafters.

Transport infrastructure is non-functional. Bitumen roads splinter and sink under erosion. Vehicles line the streets like tombstones with engines seized, tyres disintegrated from the absence of petroleum-derived rubber. Electric vehicles too lie inert, stripped of the polymers that once shielded their wiring, their lithium pathways severed by disuse. Along weed-choked highways, a wanderer cycles past grounded planes and silent terminals. No flights, no fuel, no future.

In agriculture, the impact is catastrophic. The global fertiliser regime has dissolved. Without nitrogen synthesis from natural gas and petroleum-based distribution, fields lie barren. Tractors, their tanks empty and tyres collapsed, rust in the open. Pests consume unprotected crops, while food packaging that once depended on polyethylene and polypropylene fails to preserve what little remains. Starvation spreads. Over two billion people perish from hunger. Livestock populations crash without processed feed and synthetic antibiotics.

Healthcare collapses in parallel. Hospitals no longer sterilise tools or deliver medicine. Without refined oil, surgical gloves, intravenous bags, antiseptics, medications and antibiotics vanish. Powerless generators sit outside dark operating theatres.

One healer crouches by firelight, her hands wrapped around gauze torn from old linen, dressing wounds she cannot heal. Infections once considered curable now spread unchecked. One billion people die from untreated disease. Healthcare has regressed by centuries.

The electrical grid has fractured. Turbines fail as polymer-coated wiring degrades. Solar panels and wind turbine components deteriorate without oil-based resins. Survivors burn wood and coal beneath collapsing powerlines. In a mountain settlement, villagers gather around a dying flame, their stories recounting a luminous world their children cannot imagine. The night grows darker. Cold breath fogs the air.

Extreme fuel scarcity drives desperate attempts at synthetic fuel production. Across broken regions, displaced chemists and civilians attempt to create synthetic fuel from cooking oil and alcohol. They distil methanol in vats corroded by time, often unaware of its volatile flash point near 11°C. Explosions echo through abandoned towns. Unfortunately help never arrives as emergency services are non-operational. Fire engines and ambulances are static monuments to their former heroics. They lie stranded and dry- as a result, chemical flames consume entire districts. Smoke poisons the air and ash covers what little remains. Over two hundred million people die in fires and chemical exposure, as improvised refineries detonate across the declining world.

Amidst collapse, conflict erupts. Nations hoard their remaining reserves. Countries launch incursions for control of depleted wells. Military aircrafts and tanks roll and aircraft strike, burning the very reserves they seek to capture. By 2080, energy drives one fifth of all global warfare. Over one hundred million people are killed in resource-fuelled conflicts.

Strategic alliances disintegrate. Borders blur. Governments fall. Diplomacy is replaced by the barter of blood.

Civil institutions dissolve. Police forces abandon posts. Schools close. Communication systems fail. Skyscrapers lose their external coatings and succumb to rust. Bridges collapse without polymer reinforcement. Engineers no longer exist to repair them. In forgotten libraries, a few scholars clutch brittle texts, trying to preserve blueprints for machines that can no longer be built. A teacher reads by candlelight. Her pupils, wrapped in wool, listen as if hearing a legend.

Mental health deteriorates. With modern comforts eradicated and despair rising, suicides claim over one hundred million. Anxiety, isolation and starvation run rampant. Public services and support structures vanish. Fires rage unchecked. Death from trauma, untreated illness, and conflict pushes the global death toll past three billion.

Urban centres become uninhabitable. Dense ash clouds obscure the sun. Temperatures fluctuate without stabilising energy grids. Food systems collapse, medical response falters, and global trade disintegrates. International commerce, once powered by 90% petroleum-based freight, has ceased. Supply chains are broken. Wealth is no longer measured in gold or currency, but in preserved litres of fuel or lubricant.

With oil extinguished, civilisation enters a prolonged twilight. No aircraft cross the sky. No machines sing with purpose. The age of petroleum, which once powered spaceflight, globalisation, and modernity, ends not with a bang, but in gradual suffocation. The infrastructure of progress erodes into memory. The silence that follows is not peaceful. IT IS ABSOLUTE!

THE PATH AHEAD: CAN WE CHANGE OUR FATE?

Oil weaves our lives, from the plastic in your hand to the roads beneath your feet, a silent architect powering 104 million barrels daily in 2024. Yet, its end looms, a spectre of collapse where wars burn the last drops, 70% of the world’s population dies due to war, disease and despair, and cities crumble to dust. None of us craves a world without oil’s gifts, not after glimpsing the catastrophic reality that awaits us if we stay this path. How do we avert this doomsday? Can we conserve, innovate, or shift before the last barrel runs dry? Stay tuned for our upcoming blog, where we dive into oil conservation, renewable paths, and strategies to delay or avoid this fate, charting a course to a future where collapse is not our destiny.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation