Software maximises mineral recovery

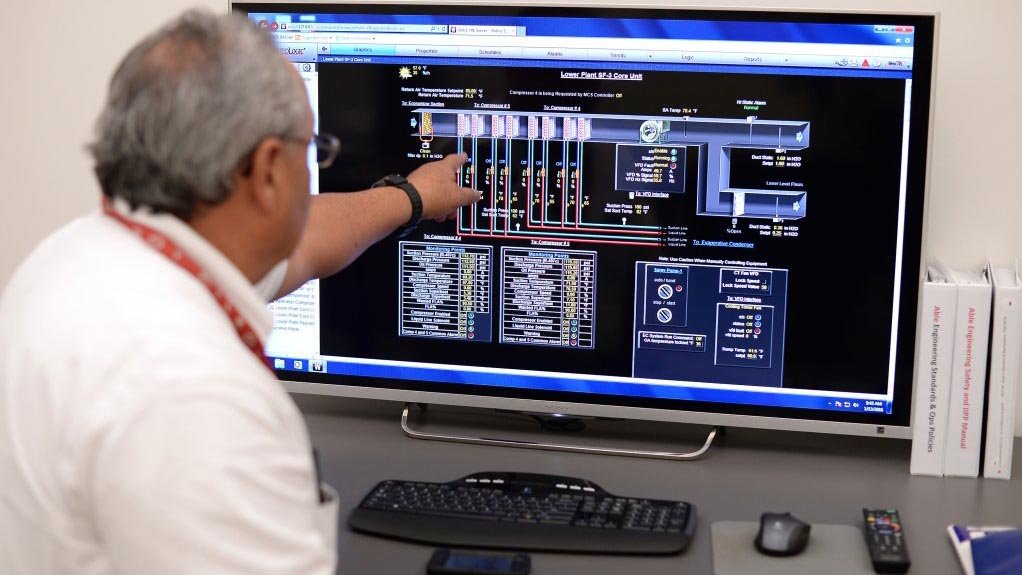

VIRTUAL CHANGING REALITY Advanced process control software essentially creates a virtual plant where engineers can predict and manipulate outcomes by changing plant variables

STREAMLINING COMPLEX PROCESSES Since the flotation plant was commissioned, the base metals miner has seen a reduction in reagent use

Process management specialist BluESP’s advanced process control (APC) solution uses software that incorporates multivariable-model predictive control to manage and stabilise complex interactions in industrial processes and maximise mineral recovery processes at mining companies, says BluESP chief engineer Dr Kevin Brooks.

He explains that the APC software enables companies to improve product quality and reduce energy and raw material use; it is also comparatively cost effective, while maintaining safe and reliable operation.

“Numerous tests are done to collate data and build plant models based on how a process works. This essentially creates a virtual plant where engineers can predict and manipulate outcomes by changing plant variables, such as energy consumption or raw material use,” notes Brooks.

He points out that this predictive ability is the foremost benefit of the APC solution, which enables companies to adapt real-time floor process to achieve optimum efficiency.

The company is completing multiphase projects for a base metals mining company in Australia and a platinum producer in Rustenburg, in the North West, he states.

Brooks says the first phase of the Australian project has been completed. BluESP, following the completion of a cost-benefit analysis and weeks of testing, used APC to optimise the flotation process at one of the flotation plants by streamlining the process.

The benefits of APC are immediately noticeable, says Brooks, pointing out that ,since implementation, the base metals miner has seen a reduction in reagent use, which will ultimately create a reduction in operational costs. The miner is also closer to its aim of maximising recovery at a certain grade, which will increase profits. Brooks states that, as “BluESP’s solution is software based . . . clients typically notice a return on investment within six months”.

Since the flotation plant was commissioned, he says, the new system – predominantly controlled by artificial intelligence rather than human operators – has gained 95% acceptance by operators, which is “practically unheard of”. Typically, operators are reluctant to trust a computer-based system rather than their ‘gut feeling’ on how certain elements of a process should function. However, Brooks notes that operators at the Australian project accepted the system because they were completely aware of the associated benefits.

The testing, modelling, installation and commissioning of the first flotation plant took about nine months to complete, despite BluESP, as a South Africa-based company, having to computer-based system rather than their ‘gut feeling’ on how certain elements of a process should function. However, Brooks notes that he travelled to Australia for the cost-benefit analysis and first rounds of testing. He says the project and the next few phases have no particular schedule, partially because of the challenges pertaining to the geographic distance.

The miner is willing to tolerate the challenges associated with the distance because BluESP is the preferred implementation partner of global process software company Aspentech, Brooks states. BluESP solutions predominantly use AspenTech software such as DMC+.

“We’ve been the preferred implementation partner for AspenTech software for about six years . . . When the client first contacted AspenTech’s Australian partners, they reached out to us.” He comments that this is indicative of BluESP’s credibility and quality of service.

BluESP has also completed the first phase of the Rustenburg platinum project, which aimed to stabilise mineral processing by allowing for the on-line control of real-time floor processes. “The system [is] similar to the cruise control feature of a car, is based on input or programming from the user and operates in a certain manner, similar to a driver setting the speed on cruise control. However, operators can make certain changes within the control parameters if needed, similar to a driver braking when necessary.”

Brooks notes that this project has required multiple units across multiple phases, with the first of the three units required for Phase 1 already completed.

Since its establishment in 2000, BluESP has introduced and implemented APC solutions in the mining sector, specifically the mineral processing sector, which, prior to BluESP’s flagship project with Anglo American Platinum in 2009, was regarded as too variable to control.

“Mineral processing and recovery typically involve multiple types of ore, reagents, liquids and other solids,” Brooks notes.

This meant that implementing a system based on broad parameters would work efficiently, but not necessarily optimally. A system based on specifics would work optimally under certain circumstances, but would be too rigid for an industry as unpredictable as mining, making it impractical. However, APC, which accounts for almost every variable, enables the user to create specific processing procedures, while allowing the system to adapt to a change in variables.

Brooks notes that BluESP is considering potential projects in the gold and copper sectors, noting that the potential for APC implementation in the global mining sector is significant. The company continues to offer solutions to the petrochemicals and manufacturing industries.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation