Africa’s green future is now thanks to thyssenkrupp Uhde’s cutting-edge green technologies solutions

This article has been supplied.

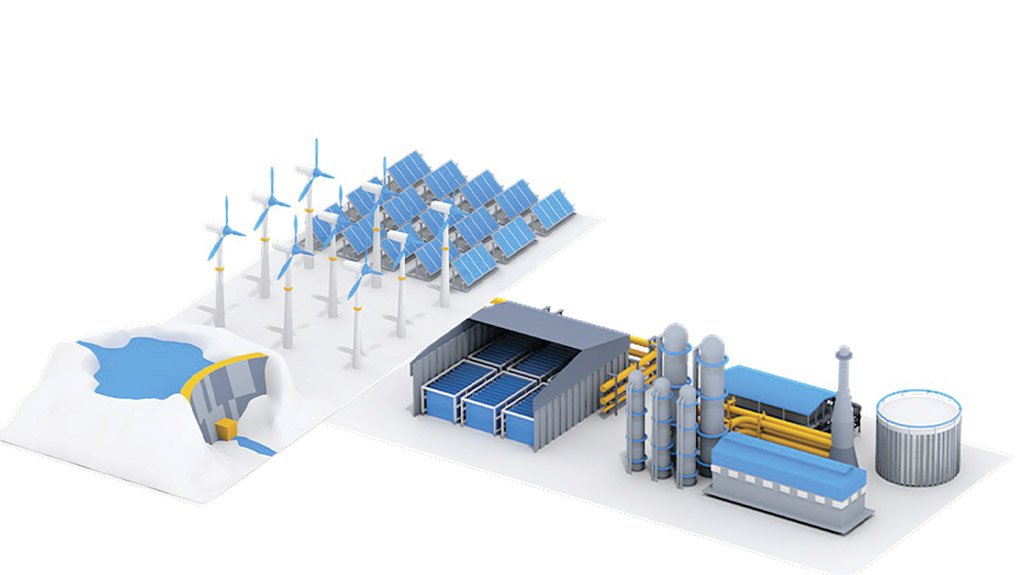

thyssenkrupp Uhde, as a proudly environmentally-conscious company, is helping to green the planet through itsleading-edge green technology solutions. Combining decades of experience and expertise, the company owns a large portfolio of chemical process technologies, including those for the production of green chemicals such as green ammonia and green methanol. For large scale green hydrogen production based on alkaline water electrolysis, thyssenkrupp Uhde collaborates with its sister company, thyssenkrupp nucera.

The global adoption of green hydrogen and fuel cell technologies for clean energy andtransport applications is rapidly gaining traction as the urgency to tackle climate change accelerates. Energy transitionholds great potential for Africa, unlocking thecontinent’s economy through newsustainable energy investments andbecoming an exporter of clean energy.

In South Africa, insecurity of energy supplyand its accompanying negative effects onthe country’s economic growth is speedingup the demand for the green energytransition. Decreasing the country’s dependence on coal-fired power stationsand moving to renewable or clean energygeneration is the way forward. It holdscountless advantages that will underpineconomic growth and stimulate foreign investments. According to a recentstatement by the Global Wind EnergyCouncil (GWEC), the cleanenergy transition has the potential to create 250000 jobs in South Africa over a period of 25years. South Africa’s energy security canbe addressed by fast tracking projectsfocussed on green energy i.e. wind, solar and green hydrogen.

thyssenkrupp Uhde’s Senior Sales Engineer, Nithesh Mohun, notes that the rapid deployment of these green technologies is essential. “Fortunately, South Africa’s climate and geography are well suited for a hydrogen economy; we have an abundance of sun and wind as wellas large expanses. In line with the SouthAfrican Government’s hydrogen strategy,massive investments are being made in infrastructure for the large-scale production of green hydrogen. This includes the development of the Green Hydrogen Valleyproject in the Provinces of Limpopo, Gautengand KwaZulu-Natal.”

Mohun unpacks the potential of green hydrogen, noting that it is so much more than a mere zero- carbon energy carrier. As an enabler, green hydrogen is the basis for other green technologies. It can be used to create a suite of products including green ammonia, explosives, green methanol, synthetic fuels, and synthetic natural gas. Moreover, green hydrogenapplications include mobility and power generation via fuel cells and can be conveniently stored for deployment whenneeded.”

While the world clearly wants hydrogen,Mohun points out that getting it to countries in Europe for example, poses a challenge. He explains: “Gaseous hydrogen takes up more space than liquid hydrogen. Transporting large quantities of it in gas form is not feasible. Therefore, the solution would be to transport hydrogen as a liquid and to then convert it to gas at the point of storage or use. However, this requires the energy intensive liquefaction process, which itself is not economically feasible. We therefore look at hydrogen carriers as an alternative. We can take the hydrogen we produce and combine it with nitrogen to produce ammonia, a high-density energy carrier.”

thyssenkrupp Uhde has a CO2-free green ammonia production solution based on thyssenkrupp nucera’s AWE technologyand 100% renewable feedstocks. OnceEurope receives the ammonia, theammonia can be cracked to hydrogen and nitrogen at the point of receipt. The associated cracking technology is also part of the ThyssenKrupp portfolio.

When green hydrogen is combined with carbon dioxide green methanol can be produced. Methanol, like ammonia, is also a feasible energy carrier. Methanol is used as a raw product in the manufacturing of plastics and polymers. Itis also used as a fuel additive for cleaner,less harmful CO2 emissions during combustion. thyssenkrupp Uhde also offers carbon capture technology for cleaning up the gases that are emitted into the air from smoke stacks. The harmful substances that have been captured can be stored and beneficiated later.

Green technologies also hold advantagesfor Africa’s agricultural industry with greenammonia and green urea serving as green fertilizers. All that is needed for the production of green urea is ammonia and a source of CO2.With over four decades ofexperience in the design and construction of urea plants, thyssenkrupp Uhde is regarded as one of the top international contractors in this field.

South Africa is advancing into greenammonia solutions with a proposed greenammonia export facility planned for construction at the Coega Special Economic Zone in Nelson Mandela Bay, Eastern Cape. According to variousreports, the facility shall produce up to780,000 ton-per annum of green ammonia with full operation scheduled by the end of 2026.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation