Bell launches new Bell Heavy Industries division

Bell Equipment has 45 000m² undercover manufacturing area in Richards Bay that complies with the ISO 9001:2015 Quality Management System and welds to the internationally recognised ISO 3834-2 Appendix 10 standards

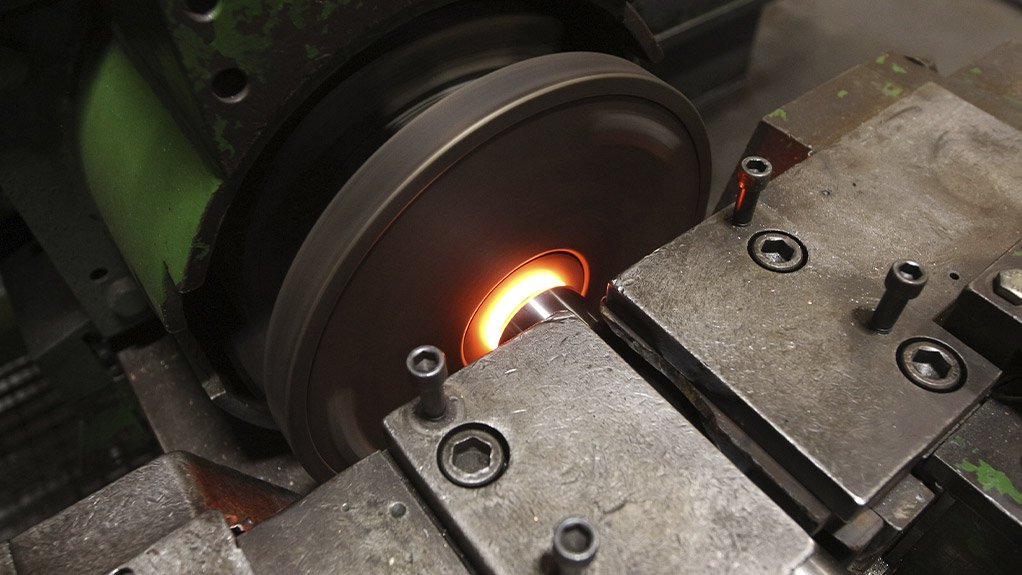

With an onsite friction welder providing superior fusion and weld penetration, BHI manufactures cylinders and struts of various lengths and diameters and has the capability to cycle and pressure test these during the manufacturing process

BHI is capable of oxyfuel cutting up to 75mm material thickness, plasma cutting up to 32mm, and laser cutting to 12mm of a variety of metal sheets

The Bell team in Richards Bay of over 800 machinists, welders, and assemblers is among the best in the country thanks to the company’s own training centre, which plays a crucial role in internally developing world-class skills from the surrounding community

Three robotic welders are used to optimise the quality of long, continuous welds

Onsite calibration facilities, equipment to perform material checks, and several highly specialised co-ordinate measuring machines ensure consistent quality

This article has been supplied.

With almost seventy years of demonstrated expertise in complex engineering, heavy fabrication, and machining for its own range of material handling equipment, Bell Equipment is now offering these specialist services to all industries in the country through its newly formed division, Bell Heavy Industries (BHI).

Bell Equipment’s Group Business Development Director, Stephen Jones emphasises the current scarcity of companies providing these vital services locally. “South Africa has seen a huge reduction in engineering companies, and, in response, we have strategically positioned our South African manufacturing facility to fill this void by providing project engineering and contract manufacturing through BHI.

“The growth of Bell as a well-established mining, earthmoving, and agriculture equipment manufacturer, both domestically and in terms of exports around the world, is a testament to the skills available and the quality of products that we make in Richards Bay. We’re confident in our ability to expand into other industries and believe this will benefit not only the manufacturing sector but the whole country.”

Bell has also received accolades for its demonstrated performance from organisations such as the South African Capital Equipment Export Council (SACEEC), the Mining Equipment Manufacturers of South Africa (MEMSA), and the Department of Trade and Industry, which hosts the South African Premier Business Awards together with Proudly South African and Brand South Africa.

The 45 000m² undercover manufacturing area in Richards Bay complies with the ISO 9001:2015 Quality Management System and welds to the internationally recognised ISO 3834-2 Appendix 10 standards. It is well equipped with specialist machines including both horizontal and vertical CNC (computerised numerical control) machining centres, 5-axis boring machines, laser cutters, high-definition oxyfuel and plasma cutters, bending brakes, and advanced welding technology. A blasting plant, phosphating tanks, sealed spray booth, galvanising bath, and an automated powder coating installation are available to take care of surface treatments.

The Bell team in Richards Bay of over 800 machinists, welders, and assemblers is among the best in the country thanks to the company’s own training centre, which plays a crucial role in internally developing world-class skills from the surrounding community. “This is complemented by our highly skilled team of welding, quality, and industrial engineers, along with onsite calibration facilities, equipment to perform material checks, and a number of highly specialised co-ordinate measuring machines.

“Together with our strong focus on process development, BHI can guarantee consistent quality to customers. BHI can also tap into a wealth of group resources, notably a team of over 100 South African design engineers, enhancing its suitability for local manufacturing across diverse industries,” adds Jones.

Bell Equipment’s manufacturing operation, which is 55% black-owned and 24% black women-owned, contributes to B-BBEE scores and creates localisation opportunities for potential customers. “Over the years we have established a global supply chain with access to world-class suppliers. Procurement staff are well skilled in international logistics and our strategic sourcing department has strong commodity expertise, which ensures stringent input cost control.

“We have always maintained that manufacturing has massive transformation potential for the South African economy and employment, so we are optimistic about this new division and will be actively engaging with those looking for the expertise we now offer outside of our traditional market segment,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation