Belt fastening system supplier growing footprint in S Africa

KEEPING IT TOGETHER The belt fastening systems offered by Mato Botswana keep the splices together

Conveyor belt solutions company Mato Products, a member of the Multotec Group, is ‘paving the way’ in the Botswana mining market with its innovative belt fastening systems, range of lacing equipment, and strong focus on belt cleaners.

Mato MD Benjamin Sibanda states that, since entering the Botswana market in 2018, Mato has grown significantly in innovative belt fastening and cleaning systems.

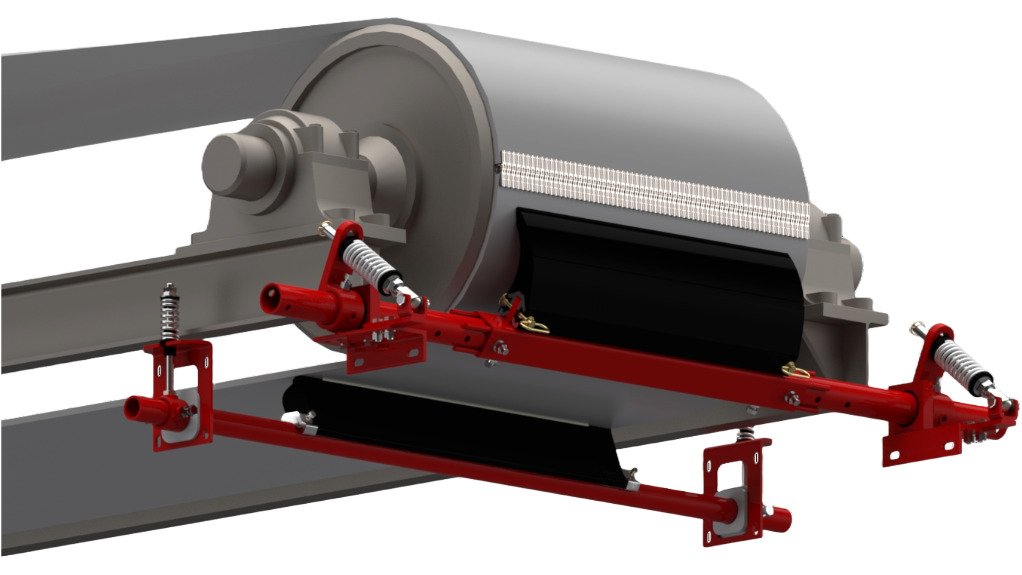

The Mato mechanical belt fastening system comprises a lacing head and bed, a wire rope winch complete with 30 m of rope, a belt clamp, a belt cutter, a belt skiver, a wave master kit, lacing pins, and fasteners.

These elements combined produce a cost-effective and durable mechanical splice.

Sibanda notes that Mato’s belt fastening system delivers a seamless joint in less than 30 minutes, which is significantly less time than the six hours required for other splicing systems. This solution reduces operational downtime, which increases productivity at a reduced cost.

“The main advantage that customers gain from using Mato products and solutions is reduced downtime,” says Sibanda.

Expecting Opportunities

“Our belt cleaning system’s market share in Botswana is immensely strong, such that our Australia-based manufacturers and suppliers inform us that we buy more of their products than any other Mato Products company in the world,” says Sibanda.

He adds that Mato currently supplies its conveyor belt solutions to two diamond mines, with an eye on the third that has two sites between its current customers. He anticipates more opportunities will arise as other mines, which are currently locked into long-term contracts with their supplier, have expressed interest in switching over to Mato systems.

“The initial demand for these products has extended beyond the coal sector into other materials handling and mineral processing applications, specifically diamond mining,” says Sibanda.

Mato supports its Botswana customers through dedicated sales engineers and access to the local Multotec infrastructure.

The support includes a full scope of value-added service including on-site assessments and installations, as well as aftersales service and maintenance.

The products supplied are manufactured in Mato Centres of Competence in Germany, South Africa and Australia.

Peace of Mind

Sibanda says that, by providing reliable and durable products, it gives customers peace of mind, as the joints often outlast the conveyor belt itself.

“In addition to this, our products are cost-effective in comparison to our competitors who typically source their fasteners and lacing equipment from international suppliers,” he posits.

Headquartered in South Africa, Mato Products currently has a team of 24 employees, including a site supervisor and technicians who are available to customers in Botswana to perform assessments and provide aftersales service.

Further, the company has two service technicians based in Botswana and is currently looking to expand this team.

He points out that for the next 12 to 18 months, Mato’s priority is to focus on marketing its belt cleaners in Southern Africa.

“Mato is more than a belt cleaning systems supplier as it is a company with products that give customers peace of mind, knowing that our solution will prolong their conveyor systems,” Sibanda concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation