Underground expansion progressing towards 2028 start

NEW ERA The scheduled start of underground production in the first half of 2028 is anticipated to bring a new era of high-value diamond recovery for Lucara

POSITIVE OUTLOOK The financial outlook for the Karowe UGP remains positive, bolstered by strong long-term diamond price projections

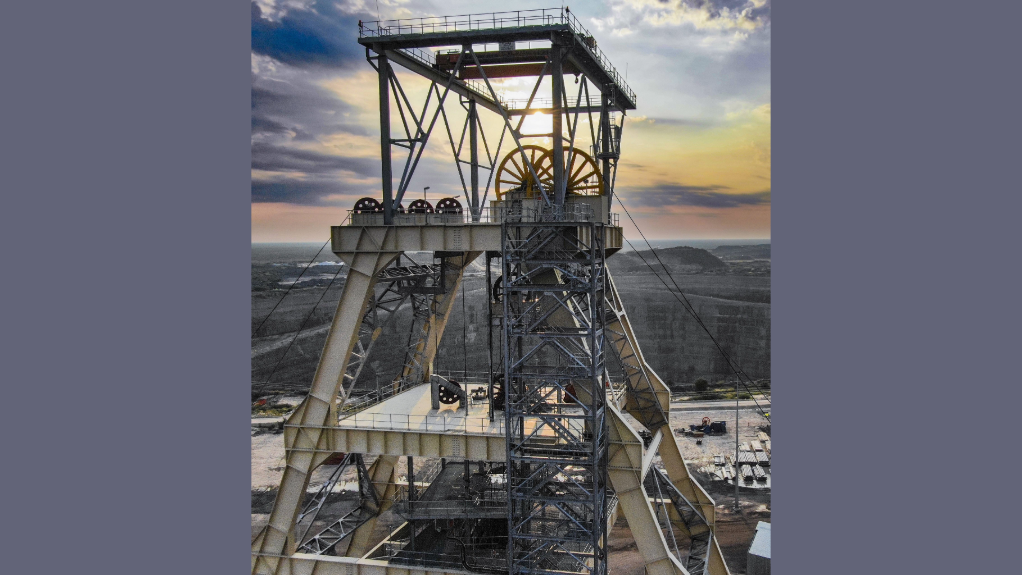

With careful planning, innovative solutions and a dedicated team, diamond miner Lucara Diamond Corporation’s Karowe Underground Expansion Project (UGP) at the wholly owned Karowe diamond mine, in Botswana, is well-positioned to achieve its goals, says CEO and president William Lamb.

The scheduled start of underground production in the first half of 2028 is anticipated to bring “a new era of high-value diamond recovery, further solidifying Lucara’s position in the global market”, he adds, noting that as the project progresses, the continued collaboration with the government of Botswana and the local communities will be pivotal.

The underground expansion targets the highest-value portion of the Karowe orebody, home to notable diamond finds such as the 1 109-ct Lesedi La Rona and the 1 080-ct Eva Star.

As early as 2026, lower volumes of high-value ore from the UGP will start to be processed, enhancing revenue prospects.

Further, openpit mining operations, continuing until mid-2025, are integral to the project’s timeline and cash flow as they will, together with surface stockpiles, provide uninterrupted mill feed until late 2027, when the UGP development ore starts offsetting stockpiles with high-grade ore.

Lamb explains that Lucara’s commitment to safety, environmental stewardship, and financial prudence ensures that the Karowe UGP will not only enhance the company’s portfolio and progress the aims of its strategic vision, but will also contribute significantly to the regional economy and the broader diamond industry.

Lucara prioritises safety, demonstrated by maintaining commendable total recordable injury frequency rate levels. The implementation of the Safe Start behavioural-based safety training programme in 2022 has yielded positive results, Lamb notes, highlighting that the miner’s continuous focus on safety and environmental compliance is central to the project’s operations.

Significant Advancements

Since earlier this year, the Karowe UGP has seen significant advancements, with shaft sinking reaching the 470-level station, following the same design as the 670-level connection, Lamb tells Mining Weekly. Both production and ventilation shafts are now approaching 70% of their final depth.

“We are finalising the design of the permanent personnel and materials winder and working on the UGP lateral development contract for the next phase,” he notes.

During the first quarter of this year the ventilation shaft reached 426 m below the collar, and the production shaft reached 449 m.

The first lateral connection between the two shafts at the 670-level was completed, including electrical and dewatering sump excavation. Permanent bulk air cooler construction also continued, with completion expected before close of the first half of this year.

In the first quarter of 2024, a total of $17.9-million was spent on UGP development, surface infrastructure, and ongoing shaft sinking activities.

Other activities undertaken in the second quarter of 2024 include continuing sinking of the ventilation and production shafts through the Mea formation into granite lithologies to the 470-level and starting 470-level station and lateral development.

Procurement of underground equipment and major components for the crusher and dewatering pumps also progressed, alongside the commissioning of the permanent bulk air cooler system.

A notable achievement for the year to date is the maintenance of a strong safety record at the project. Despite higher-than-expected water volumes and technical challenges during the shaft sinking, robust chemical grouting programmes have ensured steady progress.

Operational improvements in the first half of 2024 have been critical, says Lamb, who adds that these have been marked by innovation and simplification.

He further explains that the delays caused by the dewatering challenges in the upper section of the shafts, prompted a rebase of the project schedule in July 2023. However, the international team’s strong cultural integration has fostered collaboration and innovation, which Lamb says, have been critical to addressing these challenges.

In addition, streamlined project management and interconnectedness with current operations have optimised workstreams. “Getting the right people in the right positions has significantly enhanced the project’s efficiency,” emphasises Lamb.

With $332.5-million already spent and $64.4-million in capital commitments, the remaining budget of $683-million is strategically allocated, notes Lamb.

Major contracts, including for lateral development, are at the request-for-quotation stage. Mobilisation for these works is expected early in 2025.

He says the financial outlook for the Karowe UGP remains positive, bolstered by strong long-term diamond price projections and the potential for ongoing exceptional diamond recoveries.

“We are exploring opportunities to further mitigate the modelled cash flow impact,” Lamb concludes, adding that the company’s focus is on a “fully integrated approach underlain by a forward-looking risk assessment strategy”, which he says underscores the emphasis on risk mitigation to keep the project on time and within budget.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation