Cash prizes highlight lifting durability

This article has been supplied.

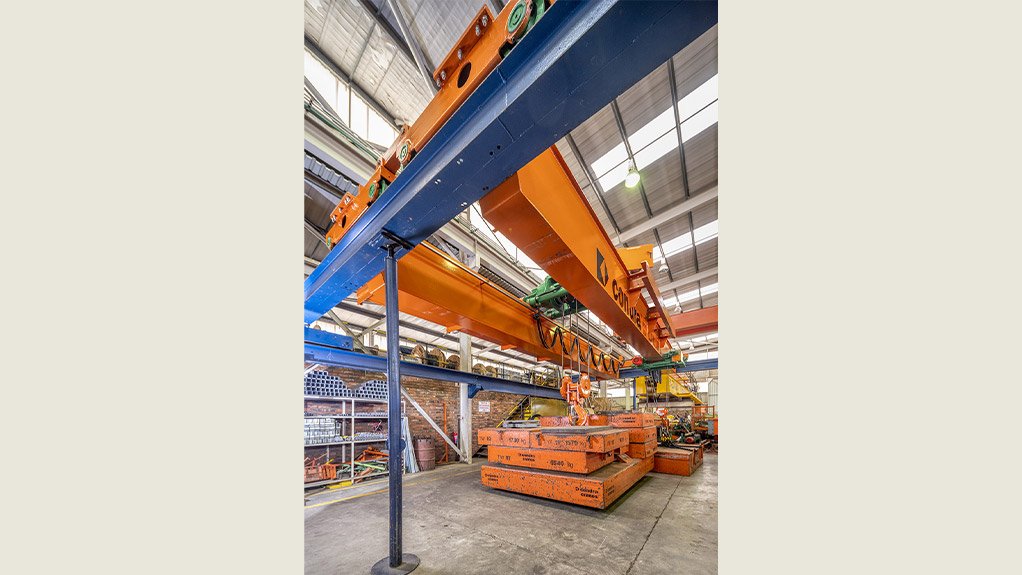

Condra is running a competition to find the company’s oldest working crane, showcasing product durability and offering cash prizes for the three longest-working machines discovered.

The contest is part of the run-up to diamond jubilee celebrations, aiming to reinforce a core company concept of delivering value over time. Open to hoists, original cranes and refurbished machines (to highlight the viability of upgrading veteran cranes to modern, fit-for-purpose standard), entry is free.

Condra will turn sixty in 2026.

Managing director Marc Kleiner said that buying new is not always the best option.

He listed the two principal advantages of crane refurbishment – an immediate realisation of cost savings, and the continued use of an as-new machine already familiar to operators. This avoids any need for retraining, he said. Production can continue as before, with no change to established procedures.

“We need about three weeks to refurbish to top standard,” said Kleiner. “The cost is almost always less than buying a new crane, and we can upgrade to incorporate any kind of modern technology the customer wants.

“Refurbishments carry a three‑year warranty if Condra-authorised agents service the crane, or one year if not.”

Kleiner explained that Condra usually refurbishes only its own cranes because spare parts from rival firms are not always available. They are also expensive to import, whereas Condra manufactures all spare parts locally.

“If the crane is one of ours, then refurbishment is usually worthwhile,” he said. “We encourage it because new crane prices are about 60% higher today than they were ten years ago. If needed, we can change crane capacity and span. Even cranes twenty years or older can usually be improved by installing variable frequency drives to facilitate easily changeable speeds.

“By refurbishing, we deliver back to the customer a crane much faster and lighter than before, and we can automate it, too, upgrading the mechanicals to work with new electrical equipment.

“These options are offered during any refurbishment, from standard 2M workshop cranes to the higher performing machines such as Class 3 and Class 4,” Kleiner added.

Turning to the market for new cranes, Kleiner pointed to worrying examples of end-users buying cheap cranes from rival firms, then finding it impossible to timeously rectify breakdowns when they occurred.

“I believe it’s fair to say that the Condra product not only works, but also lasts because it has 60 years of manufacturing and service experience behind it.”

Kleiner admitted the difficulty of competing with the sale price of imported machines in the absence of South African tariffs or other protective mechanisms.

“It’s not easy,” he said, “but where we are more than competitive is in the overall lifetime cost of the crane, because imported parts are expensive and often not readily available.

“We compete on product reliability and durability. Many operators don’t factor into their cost projections production losses caused by downtime. The purpose of an overhead crane is to move what the factory is producing. If the crane isn’t working, the factory isn’t producing. It isn’t making money.

“Initial price is not what overall cost effectiveness is all about.”

2026 will mark sixty years since Condra’s formation as a general engineering company offering a range of locally made, competitively priced hoists. Crane manufacture began in 1971. Today the company is headquartered at a 22 000m² factory site in Germiston, with a second factory in Cape Town. There are subsidiary companies in Bulgaria and Chile.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation