Company to manufacturer unique crane for diamond mine

SWIFT PROJECT COLLABORATION Competitive pricing, rapid response times during the tender process and a reputation for on-time delivery of completed machines contributed to Condra’s winning this order

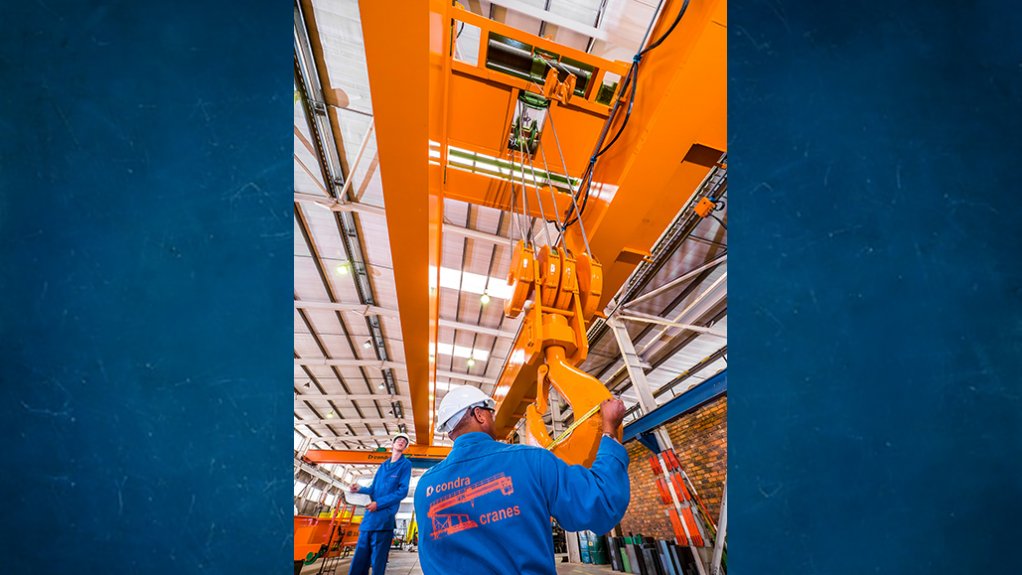

Crane manufacturer Condra is set to manufacture a 15-t suspension crane of unusual configuration as one of two overhead cranes ordered for underground use at a Botswana diamond mine.

The second machine is of conventional overhead design.

The arrangement of the suspension crane is rarely seen, as it includes two L-beams defining its area of movement that will be bolted to rock-bolt flanges and anchored in the roof of a mine chamber, after blasting, excavation and preparation as a service workshop.

The Lbeams will hang from the chamber’s ceiling, whereas they are more usually the topmost side components of a fixed gantry constructed from the ground up.

The wheeled 11 m-span crane girders will then run suspended from the lower flanges of these two long-travel L-beams, with the crane’s crab mounted atop the girders to provide the cross-travel. The whole structure of the crane becomes suspended, running along and across the roof of the chamber.

Condra designed this crane to specifications supplied by the project’s consulting engineers. By suspending the crane, it will deliver the greatest possible lifting height, reducing the volume of rock needed to be blasted and excavated to form the chamber. After installation, the crane will have a lifting height of 9 m.

Condra has previously manufactured similar suspension cranes for mines in Central Africa.

The second crane for the diamond mine will have a 35-t capacity and 9.2 m-span, with a conventional overhead design. It will work in a larger existing chamber. The lifting height will be 12.7 m.

For both cranes, Condra’s design team had to calculate balance points for individual components, precisely positioning lifting lugs on the sides of component assemblies so that they will hang precisely vertically below the cage that will lower them down the mineshaft.

Similarly, lifting lug positions atop the components will ensure balance during crane assembly and installation within the confined spaces of the service chambers.

It is thought that competitive pricing, rapid response times during the tender process and a reputation for on-time delivery of completed machines contributed to Condra’s winning this order against competition from rival companies in South Africa and abroad.

Commenting on the latest contract, a Condra spokesman said that the 15 tonner’s special configuration would make for an inspiring project on the factory floor.

“Few companies in Africa, or indeed abroad, have the design and manufacturing skills for a suspension crane of this complexity,” the spokesman says.

“It’s a very nice order to get. These are big machines, and the unusual design, welding and finishing specifications will make for interesting manufacture outside the norm.”

To reduce chipping and rust, Condra will apply an edge finish, grinding all angular steel to circular section before the application of a customer-specified protective coating.

The cranes will feature flameproofing, stainless steel panels and full weld seams in place of the more usual space-welding along the lengths of steel joints, including the girders.

Control of both cranes will be by mobile pendant. The suspension crane will feature a flashing light and siren for safety.

The consulting engineers specified brake logic to avoid overuse of the pushbuttons on the mobile pendants, as operators are prone to repeated and rapid use of this control, which causes excessive heat and wear on the braking system.

With brake logic, as soon as the button is pressed twice in quick succession, a two-second temporary block is activated, overriding the operator and correcting their use of this control.

The cranes will be used for service and maintenance applications, the suspension crane being installed in a chamber close to the orebody, where it will work on machinery used for drilling, blasting and ore removal. Such a location will save the mine time and costs, as it will eliminate the hassle related to moving the machines over a great distances to workshops near the shaft.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation