Concor implements rapid technical fix at Kusile

Concor played a key role in stabilising South Africa’s electricity supply by constructing three temporary steel flue gas stacks at Kusile Power Station

Site installation demanded meticulous planning and execution with the construction taking place in a brownfields environment

Each stack is supported by piled foundations consisting of 16 piles of 900mm diameter, varying in depth from 8m to 20m

Each stack required 4,776 galvanized pre-tensioned bolts ensuring rapid and accurate pre-tensioning

Given the temporary nature of the stacks, a single coat of red oxide primer was applied to a blasted SA2.5 surface, as the design life was limited to just three years

This article has been supplied.

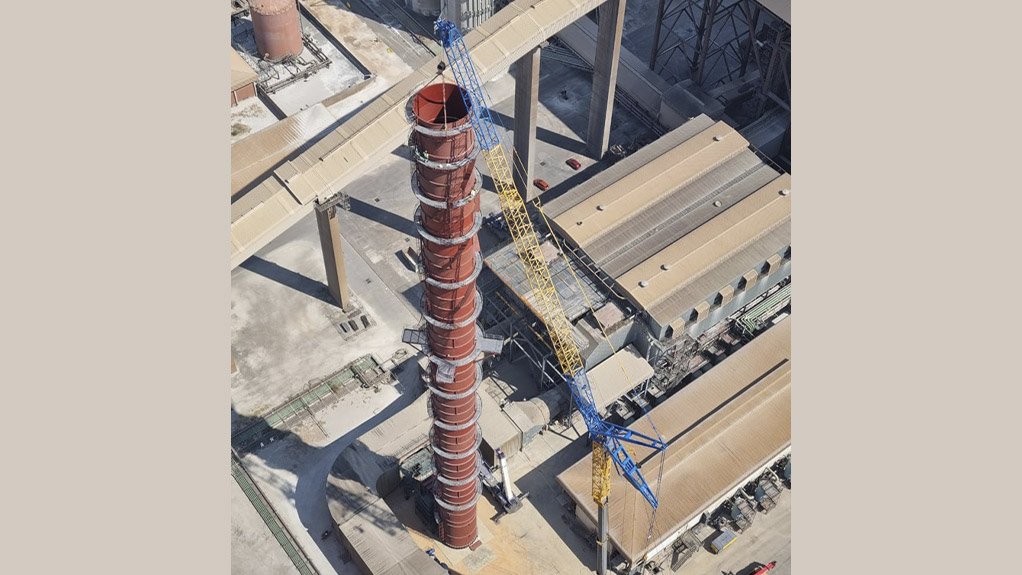

Concor recently showcased its engineering and construction expertise at Eskom’s Kusile power station in Mpumalanga by taking on a critical project to restore the power station’s boilers. This was in response to the unexpected failure of the original flue gas duct, known as the West Chimney for Kusile Unit 1, which had severely impacted South Africa’s electricity supply. The project involved constructing three steel flue gas stacks, each using 605 tons of steel, to urgently bring the boilers back online.

Juan Passmore, Project Director, Kusile Chimney West – Repair & Related Works Project at Concor, explains that the temporary nature of the structures and the tight deadlines required the team to execute the project rapidly while ensuring that materials and subcontractors were available to meet the demands. The design, intended for eventual dismantling once the West Chimney was repaired, added complexity to the project.

“In collaboration with ICC Commonwealth, Concor selected steel as the optimal material due to its availability and suitability for the accelerated schedule. Early acquisition of the necessary steel plates allowed the design process to begin promptly, focusing on the specific requirements of the project,” he says.

The final design featured freestanding structures; each 116 metres tall with a 7 metre internal diameter. These stacks were strategically located near the power station’s turbine units, and measures were taken to ensure their stability, including the addition of helical strakes to counteract wind effects.

The steel stacks were fabricated in controlled conditions at a facility in Vanderbijlpark, minimising the need for on-site work. Concor’s subcontractor worked around the clock to meet the stringent deadlines, fabricating the stacks in segments that were then transported to the site for assembly.

Given the temporary nature of the project, the stacks were coated with a single layer of primer, and foundations were laid using 16 piled foundations for each stack.

Passmore says that site installation was meticulously planned, with preassembly occurring away from the power station’s operating areas to minimise disruption. “High-capacity cranes were used to assemble the stacks on-site, with operations carefully timed to avoid wind and lightning risks,” he says. In total, 4,776 bolts were used to secure each stack, ensuring a stable and secure structure.

“Concor’s successful completion of this fast-track project underscores our capability to manage complex, time-sensitive projects in challenging environments, solidifying our leadership in the South African construction industry,” Passmore concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation