Cape Town-based nonCrete, partners offer fire-resistant building solutions

nonCrete's vaulted floor system

Photo by nonCrete

Fire-resistant bricks produced by nonCrete

Photo by nonCrete

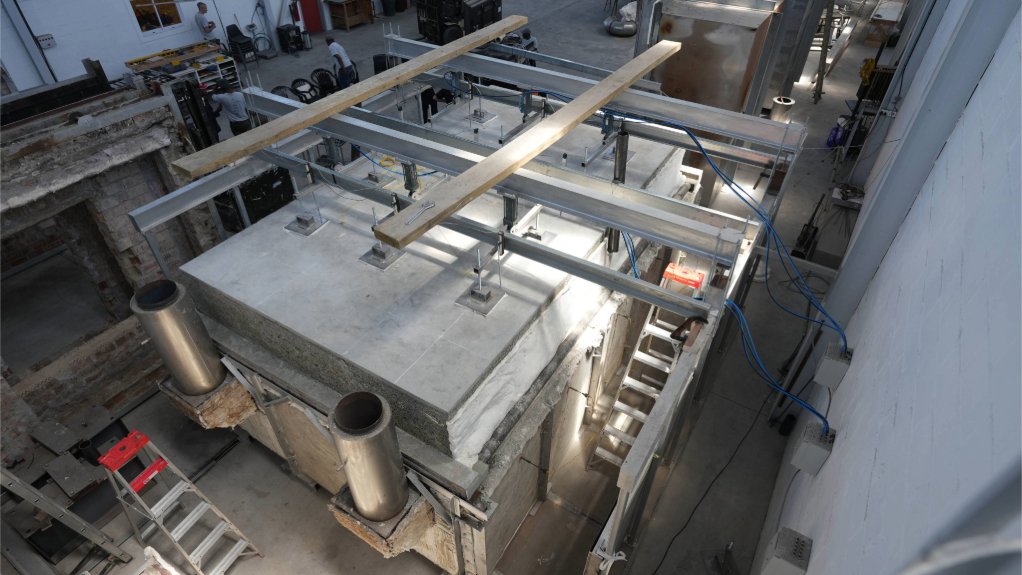

A bird's eye view of the fire test being conducted

Photo by nonCrete

The Los Angeles fire disaster and the many fires we regularly experience in South Africa are a powerful reminder of the need for fire-resistant building materials and methods across the housing and building spectrum.

Addressing this is a catalytic collaboration between Cape Town-based company nonCrete and global architecture, design and construction entity the Institute of Technology in Architecture at ETH Zurich, Switzerland, as well as South Africa's Council for Scientific and Industrial Research (CSIR) and the World Wide Fund for Nature (WWF).

They have come up with a potentially game-changing design and construction methodology for affordable, sustainable, fire-resistant buildings, with a view to revolutionising all forms of housing, building and conventional architectural practice.

In November, the newly established industrial fire resistance test facility in Cape Town, Ignis Fire Testing, tested nonCrete’s unique low-steel, low-carbon vaulted floor system. It is made from the chipped biomass of alien invasive plants mixed with a proprietary binding agent, and it passed a series of exhaustive load and fire tests with flying colours.

The formal report issued by Ignis Fire Testing reads: "To summarise the test, one can state that both the nonCrete material and the structural form behaved well when exposed to the standard fire curve for two hours".

Toward the end of the two-hour test, the temperature of the fire peaked at 1 050 °C.

The fire test was conducted according to Eurocode requirements, which are even more stringent than the South African fire code requirements. The nonCrete floor passed all the Eurocode requirements across all building sectors. The report says there was "little charring, no spalling, no flaming and no smoke emissions" and that the material remained stable and load-carrying, including in the cooling phase.

This is no come-lately design and construction system. nonCrete co-founders Stephen Lamb and Andrew Lord have worked on sustainable construction, design, engineering and architecture for 24 years and their method and materials have the full support, among others, of the Head of the Institute of Technology in Architecture at ETH Zurich, Professor Philippe Block, who is also head of the Block Research Group. He will be in Cape Town working with the nonCrete team and their partners in January and February this year.

“We focus on the production of fire-proof bricks and fire-proof floor and roofing systems. The bricks are the size of conventional bricks, but they are made from the biomass of local alien invasive trees that are felled from riverbanks, put through a chipper, and combined with a binder specially developed by non-Crete to create a fire-resistant, low-carbon material.

"It is extremely strong and it significantly reduces the amount of stone, sand and cement used in standard concrete bricks. The bricks adhere to standard industry requirements and in some cases, exceed them. Apart from their fire resistance, the bricks have superior thermal qualities, helping to keep homes warm in winter and cool in summer," Lamb explains.

Using the same material, nonCrete developed a vaulted floor and roof system in collaboration with the CSIR and Block. "It is an exceptional design that follows the motto of 'strength through geometry'," says Block.

“The vaulted floor is inspired by the arches constructed by master builders in the Gothic cathedrals of Europe that are still standing 500 years later and which we are using in European design,” he points out.

“The floor and roof system significantly reduces the amount of steel and concrete required and has 75% lower carbon emissions than a conventional concrete flat slab. It complies with Eurocode load requirements for multilevel construction in residential, office and other buildings,” he adds, noting that nonCrete’s design and method warrants substantial support and investment.

“In terms of CO₂ emissions, conventional building floors are the items with the largest impact, hence the construction industry worldwide has invested a lot in low-carbon construction alternatives such as using timber.

"However, tragic events like in Los Angeles remind us of how important fire safety is, and in this sense, the nonCrete floor ticks both boxes – it has a fraction of the embodied carbon of conventional concrete but at the same time it retains and even enhances its non-combustible properties and can withstand very long fire durations without compromising the occupants safety in the first place, while also safeguarding the building fabric itself,” says Block Research Group structural engineer Andrea Menardo, who has been instrumental in the design and testing of the floor system,

The entire nonCrete process was submitted to Agrément South Africa and is in the final stages of receiving the necessary Agrément certification, which will confirm that their construction techniques exceed all regulatory requirements. Agrément South Africa is the leading regulator of non-standardised construction products, materials, and systems in South Africa. Its evaluations are done according to strict performance-based criteria, including strength, durability and fire resistance.

Professor of structural and fire engineering, and head of Fire Engineering Research at Stellenbosch University, Professor Richard Walls, who attended nonCrete’s entire Ignis fire test says: “Given the uncertainty about how emerging, sustainable biomass products perform, it’s good to see thorough testing occurring for innovative systems. Materials with low combustibility and good fire resistance like this hold promise for being used in buildings.”

Block adds that robust, fire-resistant, low-cement building materials and low-emission, resource-efficient building systems are urgently needed worldwide.

“Considering that there will be two-billion more people on the planet 30 years from now, if we were to provide adequate housing and infrastructure for the world’s population using conventional construction materials and systems, we would have to build the equivalent of one New York City every month for the next 40 years,” he explains.

“This is what appeals to me about nonCrete’s methodology,” Block continues. “It aligns with the urgent need to change the way we design and build our structures and to disrupt the concrete, steel and carbon-intensive construction technologies for architecture.”

Lamb says: “We want to partner with construction companies, cement manufacturers, planners, architects, engineers and municipalities. And we need government to invest public funds in the nonCrete methodology for housing projects.”

“Millions of people are still waiting for government-funded homes, and the country has to invest in affordable, sustainable, more dignified housing. Our approach addresses the alien invasive tree infestation in our rivers that are seriously depleting South Africa’s limited freshwater supply, it reduces the carbon footprint and the use of steel, sand and cement, and it creates jobs as the people living in areas with alien invasive tree infestation, can be trained to fell the trees, do the wood-chipping and brick-making on site and help to build the houses.”

Lamb adds: “Our goal is to share this technology and acquired knowledge worldwide, including with the Governor of California or the relevant authority there. Wherever requested, the nonCrete team is also happy to train people to build their own houses in areas with an abundant supply of alien invasive tree species.

“In Cape Town, we have been collaborating with One-Nil Construction, led by Grabeth Nduna who has a black economic empowerment small, medium-sized and microenterprise enabled by nonCrete, the CSIR and WWF SA, and to whom we subcontract skills development and work opportunities. Nduna and two other members of the nonCrete team, Peter Mafuwe and Mojalefa Thelingoana, have been pivotal in creating the material mix designs we require.”

The nonCrete methodology is currently being pursued in a three-year project co-funded by the WWF Nedbank Green Trust and the CSIR’s Circular Economy Demonstration Fund. Called ‘alien biomass to housing’, it started last year in partnership with nonCrete, the nonprofit Phuhlisani, and the Elandskloof community near Citrusdal in the Western Cape.

Elandskloof is situated in the valley of the Groot Winterhoek Strategic Water Source Area (SWSA), one of 22 key water sources for South Africa. Its riverbanks are full of the alien invasive black wattle and the removal of these trees within a 50 km radius will have huge impact in freeing up available freshwater. SWSAs cover less than 10% of South Africa’s land surface but provide more than 50% of the entire country’s water.

Dr Coralie van Reenen, research group leader of Infrastructure Innovation at the CSIR, says “The Elandskloof project is an opportunity to demonstrate the principles of a circular economy in practise and promote the uptake of innovation for sustainable human settlements. The circular economy is a key area of research with enormous potential to impact environmental sustainability and resource efficiency, and is particularly relevant in the built environment, which is cited as contributing almost 40% of global greenhouse-gas emissions.”

Helen Stuart, WWF’s programme manager for Partnership Development and Knowledge Sharing in the Freshwater Portfolio, who is coordinating the Elandskloof project for the WWF Nedbank Green Trust, says: “In my 16 years with WWF, this is one of the most exciting projects I have been part of in terms of its socioeconomic and environmental impact, and the quality of the design and building materials makes it desirable across the economic spectrum.”

By Heather Dugmore

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation