Dual-speed fans provide air-on-demand in PGM mine

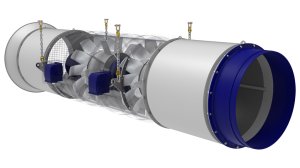

READY-TO-GO To supply the Sandsloot Underground exploration decline shaft with dynamic ventilation, Dwyka undertook the sourcing, assembly, testing and delivery of Australia-made fans, to the mine in Limpopo

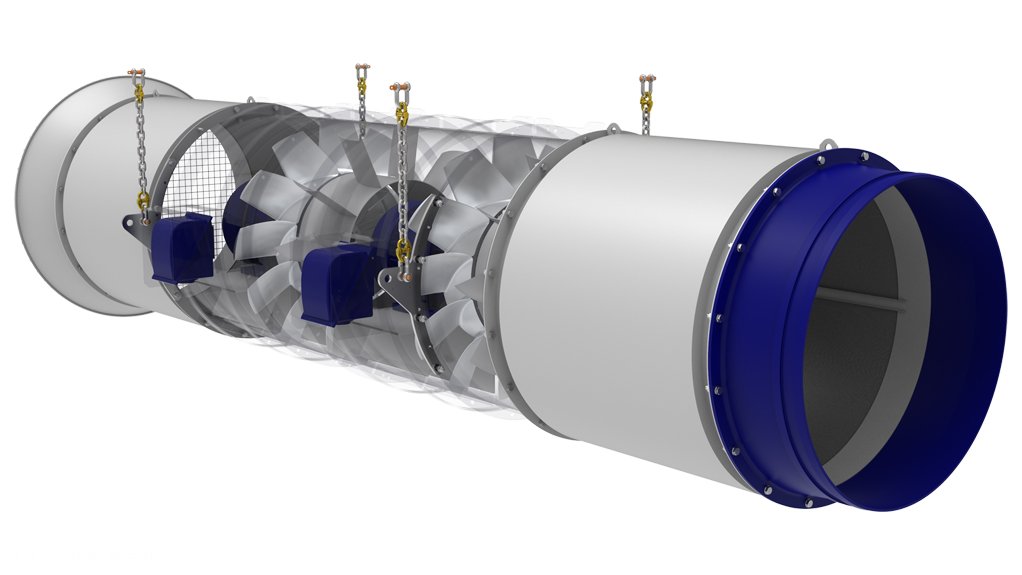

EASY INSTALL The Clemcorp fans were installed using the company’s Suspension Wing design, enabling their easy and safe installation, even in tight underground spaces

A ventilation-on-demand (VoD) system was commissioned by South African technology integrator and mining services company Dwyka Mining Services for the Sandsloot Underground exploration decline shaft of platinum group metals (PGMs) miner Valterra Platinum’s Mogalakwena mine.

The VoD package comprised two dual-speed CC1400Mk4 axial fans, which Dwyka sourced from its fans supplier Clemcorp Australia.

The fans, fitted with two custom wound motors of 110 kW (four pole) and 37 kW (six pole), offer four modes of operation, including a low-speed setting designed specifically to limit the volume of air drawn down from the decline, while the higher speed provides flexibility and degrees of responsiveness for ventilation control aligned with real-time mine requirements.

The dual-speed fans allow the switching between high speed (14 95 rpm) and low speed (990 rpm) settings, which enables the delivery of “just the right amount of air when and where it’s needed”, Dwyka CEO Jamie van Schoor tells Mining Weekly.

“By dropping the speed by just 30% we still maintain 70% of the airflow delivered but drop the power consumption from 110 kW to 37 kW, providing huge operational savings,” explains Clemcorp Australia GM Justin Coetzee.

By adjusting the fan’s speed to match real-time ventilation needs, not only is efficiency improved, but the mine’s future environmental, social and governance commitments are also supported, with measurable results across the PGM industry, adds Van Schoor.

This operational versatility enables the optimisation of airflow, reduces energy consumption and mitigates ventilation challenges such as air recirculation and damage to ducting, particularly as ducting is extended in newer development ends of a mine.

Further, with ventilation costs generally regarded as 60% of an underground mine’s electrical costs, he says dual-speed fans enable controlled ventilation “that’s smart, energy-efficient and much more cost-effective”.

Working closely with Valterra and Clemcorp, Van Schoor says Dwyka helped specify and select a suitable fan to experiment with a VoD setup that could adapt to changing underground conditions and allow for greater control of energy management.

“As Clemcorp Australia’s trusted agent in Africa, we brought over a decade of ventilation expertise and innovation to the table.

“This was all about finding the right balance between performance and cost, something critical in today’s PGM environment where every rand counts,” he notes.

The fans are controlled using custom-built starters with both local and remote access, giving teams flexibility underground and from surface.

“We call the system ‘EZ-VoD’ because it takes the complexity out of VoD,” enthuses Van Schoor.

To complement the fan systems, Clemcorp supplied custom-designed dual-speed starter

panels which enable the automated control of fan speed transitions, ensuring smooth and efficient adjustments between operating modes in response to evolving ventilation demands.

Importing, Commissioning

The essential fan components were imported from Australia using a flat-pack shipping model, after which they were built in South Africa by Dwyka.

While the dual-speed motors were wound in Australia for quality assurance, Van Schoor points out that Dwyka technicians recently underwent training in Perth, Australia, enabling them to handle the rest of the fan build, locally.

“This ‘glocal’ approach helps us deliver world-class global technology in a way that makes long-term financial and environmental sense for local operations,” he says.

For this project, Dwyka undertook the sourcing, assembly, testing and delivery of the fans, following which a team from the mine undertook the installation and final commissioning.

“We manage the process end-to-end, making sure that when the equipment arrives, it's ready to go with minimal effort. After commissioning, we stay involved with performance tracking and technical backup and helping the site get the most out of the system,” says Van Schoor.

The Clemcorp fans were installed using the company’s Suspension Wing design, which Van Schoor says enables their easy and safe installation, even in tight spaces underground where traditional PGM mines can pose a challenge.

In terms of growing local content incorporation, Dwyka started with imported fan motor starters for the Valterra project but has since developed and type-tested locally engineered fan starters for other clients.

“These integrate with Ventsim CONTROL, allowing for real-time remote control, airflow setpoint changes and full visibility into performance metrics especially important in deep, complex declines for safety and monitoring considerations,” explains Van Schoor.

“What really sets this project apart is how smooth it went. Our teams worked closely with Mogalakwena personnel to make sure everything fitted into their existing infrastructure,” concludes Coetzee.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation