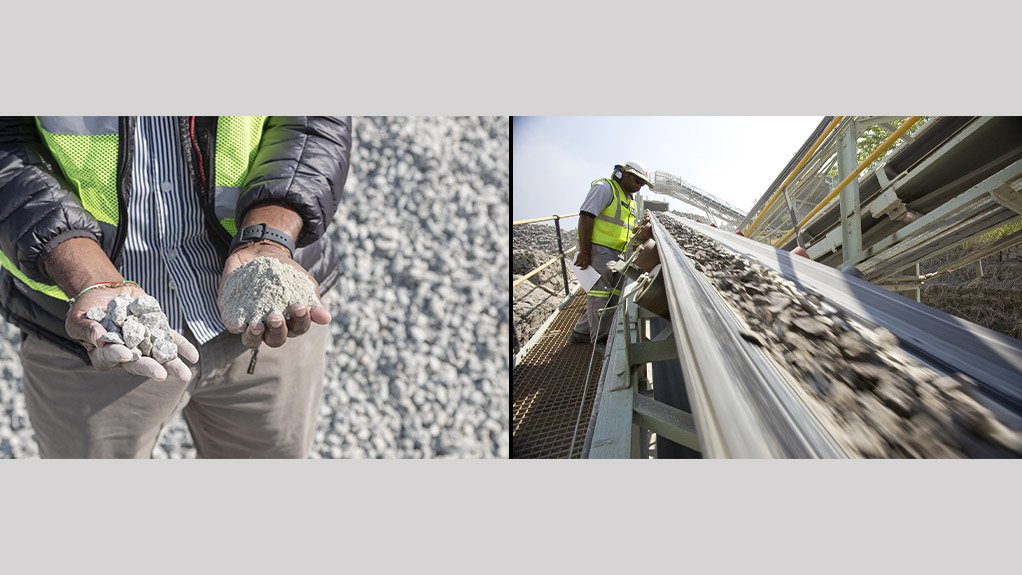

Ensuring quality aggregates for reliable construction

In the construction sector the correct sizing and grading of aggregates can determine the strength, durability and long-term performance of a structure, with poorly graded aggregates potentially leading to reduced structural integrity.

“Aggregate grading is about more than just particle size,” explains AfriSam construction materials executive: sales and product technical Amit Dawneerangen. “It determines how the material compacts, how concrete mixes perform and how well loadbearing structures can handle stress over time.”

When aggregates - whether used in concrete, asphalt or base layers - are incorrectly sized or poorly graded voids can occur within the mix, reducing density and compromising strength. This can lead to cracking, shrinkage and water ingress - all of which can shorten the lifespan of roads, buildings or infrastructure.

Conversely, well-graded aggregates create dense cohesive mixtures that enhance workability, reduce cement or binder demand, and ensure more uniform compaction and stability.

Beyond physical performance, consistent aggregate quality helps engineers and contractors to meet design standards and regulatory specifications.

Technical expertise, process control and rigorous testing are regarded as key to ensuring precision sizing and grading of aggregates.

“Partnering with an established, credible supplier provides confidence that every load delivered meets specification,” asserts Dawneerangen. “It also means access to reliable technical advice and traceability - from the source rock right through to the final product.”

He says AfriSam implements regular laboratory testing and maintains calibrated crushing, screening and blending processes to ensure product consistency.

In addition, the company collaborates with engineers and contractors to ensure that the correct material is selected for each layer or mix design, aimed at reducing the risk of costly rework and ensuring long-term performance.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation