Equipment supplier adapts to meet industry needs

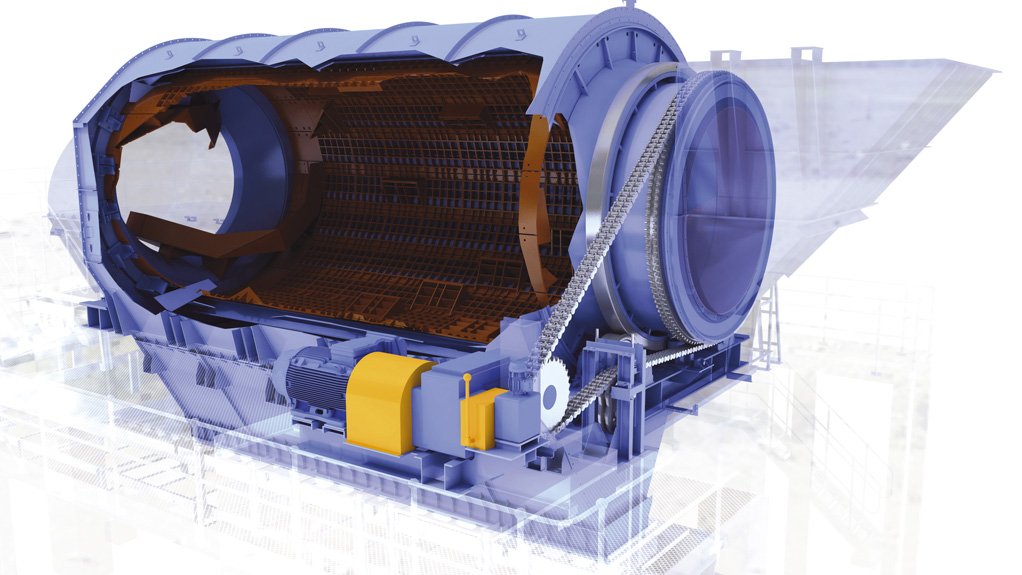

BRADFORD BREAKER The coal breaker has and its support structure have been designed for easy relocation to a new mining area

Mining equipment supplier Tenova Takraf Africa is offering junior miners in the surface mining industry a tailor-made package that will help new mining operations produce State-owned power utility Eskom-grade coal.

The package, available since 2015, comprises a breaking and destoning plant, consisting of a rotary coal breaker, conveyor system, primary crusher and spreader system.

Tenova Takraf engineered technologies GM Richard Späth explains that the company has supplied two breakers to junior miners in the past, with one of the projects developing into an ‘Eskom-type’ coal processing plant.

He points out that this “Eskom package” is in line with Tenova Takraf’s new market strategy, which has been refocused to deal with the challenges that resulted from the commodity price slump between 2011 and 2016, up to which point the company grew “phenomenally”.

This rapid growth was fuelled by the upbeat economic climate at the time, which made it possible to focus on bigger equipment and larger projects. However, a refocus since 2011 on the supply of solutions tailored to smaller mines operated by junior miners was subsequently necessary, Späth explains.

“When I say refocus, we’ve not moved away from doing the big stuff. It’s just that there are fewer of those large projects in the market; therefore, we’ve had to adapt to ensure that we are able to meet present market demands.”

Opencast Solution at Electra

Späth says the company introduced several innovations at Electra Mining Africa 2016, held at the Johannesburg Expo Centre, in Nasrec, in Johannesburg. The design of one such innovation, the Tenova Takraf-developed semimobile version of the Bradford coal breaker, was launched in 2015. The company has since sold two units to junior miners in the coal mining industry.

As the breaker is semimobile, mining companies can move the equipment as mining progresses. “We see a lot of junior miners mining pillared coal; therefore, they do not remain in a specific area for a long time. They might be there for two years and then need to move their operation,” Späth notes.

The Bradford coal breaker and its support structure have been designed for easy relocation to a new mining area. Tenova Takraf markets the Bradford coal breaker in South Africa under licence to US processing solutions provider Terra Source Global.

Tenova Takraf also showcased its in-house-designed concrete module conveyor at Electra. The product is ideal for an opencast mine where mine progression takes place regularly and the conveyor frequently needs to be extended, says Späth.

He adds that, because the conveyor comprises concrete modules, it can be moved and extended on site as needed, ensuring that production is not delayed by time-consuming upgrades associated with more traditional conveyors.

“We also showcased the Dry Fog technology of US manufacturer of dust suppression systems Dust Solutions Incorporated (DSI). We started selling this dust suppression technology one year ago, following our appointment as DSI’s licensed distributor in Africa. We have sold two systems so far.”

Both systems were sold in South Africa – one to a power station and the other to a diamond mine in Limpopo. Späth explains that the Dry Fog technology does not use chemicals that are usually employed in dust suppression technology. The Dry Fog produces a very small water droplet, hence, no chemicals are necessary to alter the surface tension of the water.

“We produce a very small water droplet that matches the size of the dust particle – PM10 (less than 10 µm) – that we are trying to remove from the air.”

Tailored to Needs

Späth explains that Tenova Takraf has a laboratory facility at its South African head office in Kempton Park, Gauteng, to help its clients determine the exact equipment size needed to meet the requirements of their operations.

“Data provided by the laboratory is also invaluable for our process engineers in developing fit-for-purpose flow sheets for our projects”.

The laboratory has special drop test equipment for Tenova Takraf’s Bradford coal breakers. “Therefore, we can size the breaker according to a client’s specific coal sizes. We also have a laboratory-scale jaw crusher, a cone crusher and solid-liquid separation testwork equipment for our Delkor range of technologies, which include belt filters, thickeners and flotation cells,” he explains.

Späth points out that Tenova Takraf’s heritage in South Africa is extensive, with equipment in all sectors of the mining industry.

“Because our product range is so diverse, it covers mining industry solutions from pit to port, with our equipment in place throughout South Africa and the rest of Southern Africa,” he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation