Automated cranes gain traction despite concerns

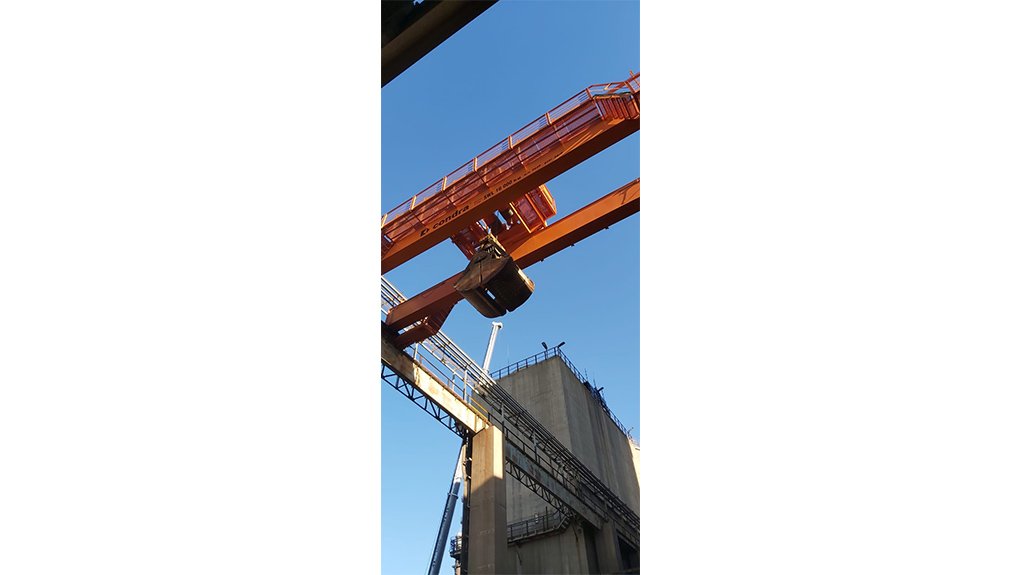

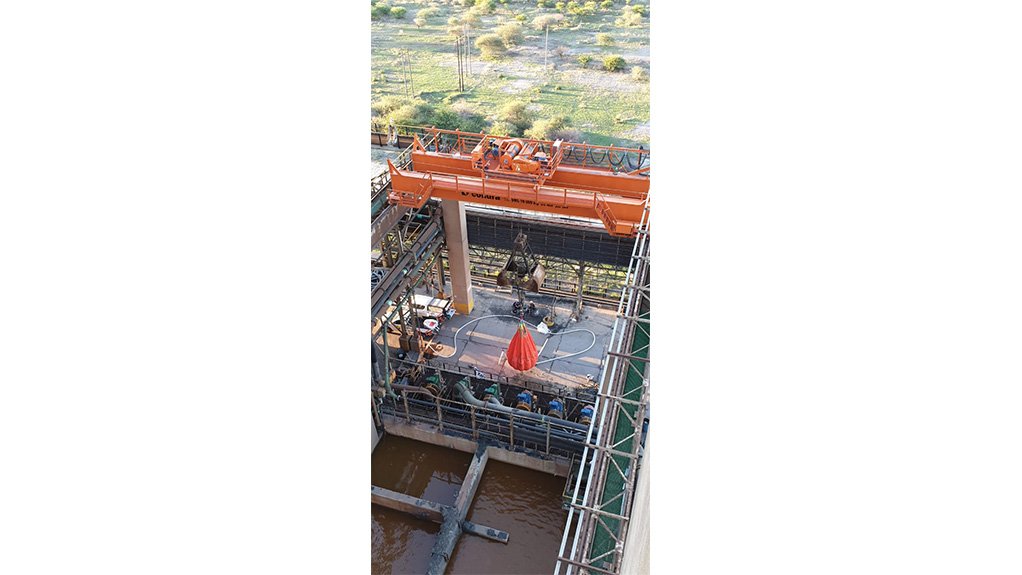

RISKY BUSINESS Automated cranes offer an increase in production and improve performance while ensuring less risk of injury to people should an automated crane malfunction

GO FOR LOCAL Local manufacturing of automated cranes can reduce downtime by decreasing companies’ reliance on imports

Amid increasing automation in Africa’s overhead crane industry, local crane manufacturer Condra Cranes has noted a significant increase in the number of tender documents specifying provision for crane automation post-installation, owing to the potential of automation to increase productivity and improve performance.

Condra Cranes MD Marc Kleiner explains that this shift is also marked by the potential of automated cranes to mitigate mistakes.

Moreover, as they reduce the number of people needed to operate at manufacturing plants, automated cranes reduce the risk of on-site injuries, should a crane malfunction.

As an added benefit, the local manufacture of automated cranes can reduce downtime by decreasing companies’ reliance on imports.

“South Africa has the technology and capability to deliver locally manufactured automated cranes and the market is becoming increasingly aware of this fact. We will [not] have to wait long before automation gains a foothold,” says Kleiner.

Full automation implies zero involvement by machine operators, while semi-automation still requires an operator to control the crane during nonrepetitive lifting functions.

Condra has offered full automation across its product range since 2020, which is the culmination of continuous development since the company’s first semi-automated crane installation at a Durban spice company in 2003.

Amid the increase in demand for automated cranes, it is crucial to note the impact that fully automated cranes and artificial intelligence could have on employment across the manufacturing value chain.

Moreover, introducing automation may require the combining of players from different industries, which Kleiner says may be difficult to integrate.

He adds that, while continuous research and development (R&D) is necessary for the heavy lifting industry, the Covid-19 pandemic halted R&D initiatives, owing to travel restrictions.

Hence, to keep abreast of emerging automation trends, Condra is planning to advance its new hoist unit this year, which promises to streamline machine maintenance by ensuring that clients no longer have to take the entire machine down to service one part.

The company is also expanding its footprint Angola, Côte d’Ivoire, Zambia and Liberia, as well as South America, where there is an abundance of critical, in-demand minerals.

“The market is aware that Condra represents more than just crane manufacture and commissioning, as it offers design and engineering skills that dovetail with those of architects and structural engineers.

“We have considerable experience of working with these disciplines to deliver world-class, best possible lifting solutions within tight lead times. This is a strong foundation on which to build a successful 2023,” concludes Kleiner.

Article Enquiry

Email Article

Save Article

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation