Heat exchangers made compact

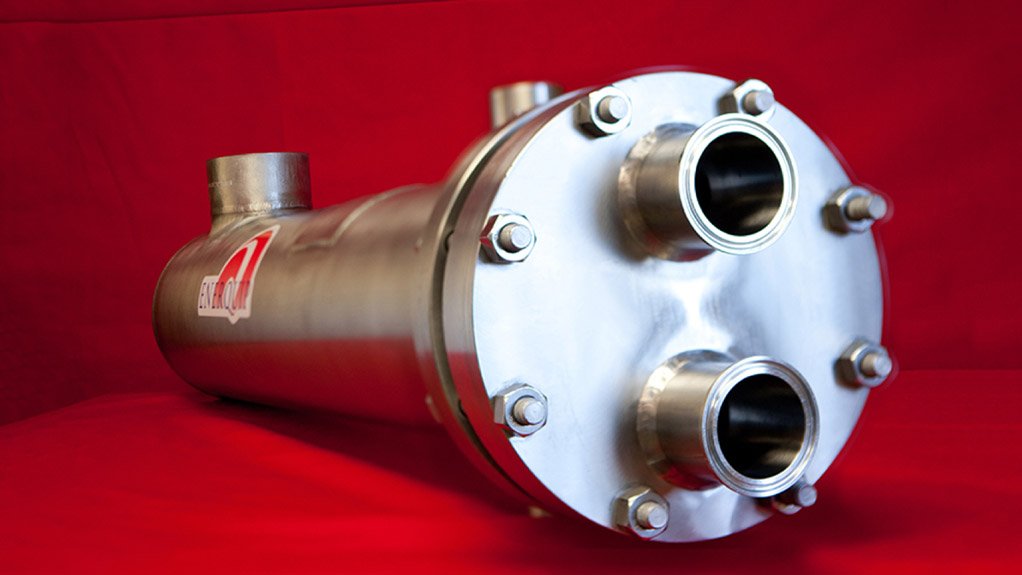

U-TUBE Heat exchangers are available in U-tube and straight tube designs, and save a significant amount of space due to their size

Wisconsin-based shell and tube heat exchangers company Enerquip has added a new line of compact heat exchangers to meet growing demands from customers with low flow-rate applications.

Enerquip describes itself as one of the leading providers of heating and cooling equipment for production plants and original-equipment manufacturers in the US, and the system integrators that support them.

Enerquip director of sales and marketing Ron Herman explains that low flow rates have until now not been catered for. “Until now, we haven’t had an efficient solution for product flow rates from one to ten gallons per minute. These scaled down versions of our exchangers use smaller tubes that keep tube-side velocities high, for better heat transfer, while avoiding problems with bypass, seen in larger exchangers when they are used at low flow rates.”

The heat exchangers – available in both U-tube and straight tube designs – are easy to clean, save space and are built to last. Enerquip’s compact exchangers are also American Society of Mechanical Engineers (ASME-) -approved, reassuring customers that their product will be safe during production.

The sanitary version also meets the rigorous 3-A sanitary standard, ensuring that equipment designed and fabricated according to the criteria will be cleanable. The pharmaceutical models are more ASME-bioprocessing equipment compliant than other low-flow coil models and other current designs in the market.

Enerquip enthuses that the new product line is ideal for small-batch processes, point-of-use streams, research and development, or pilot-scale applications, where a smaller compact exchanger would be an advantage.

Enerquip’s heat exchangers are typically used in the pharmaceuticals, beverage, brewing, food processing, dairy, paper, chemicals, wastewater and renewable fuels industries.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation