How Pyrotec PackLink Makes a Difference

This article has been supplied and will be available for a limited time only on this website.

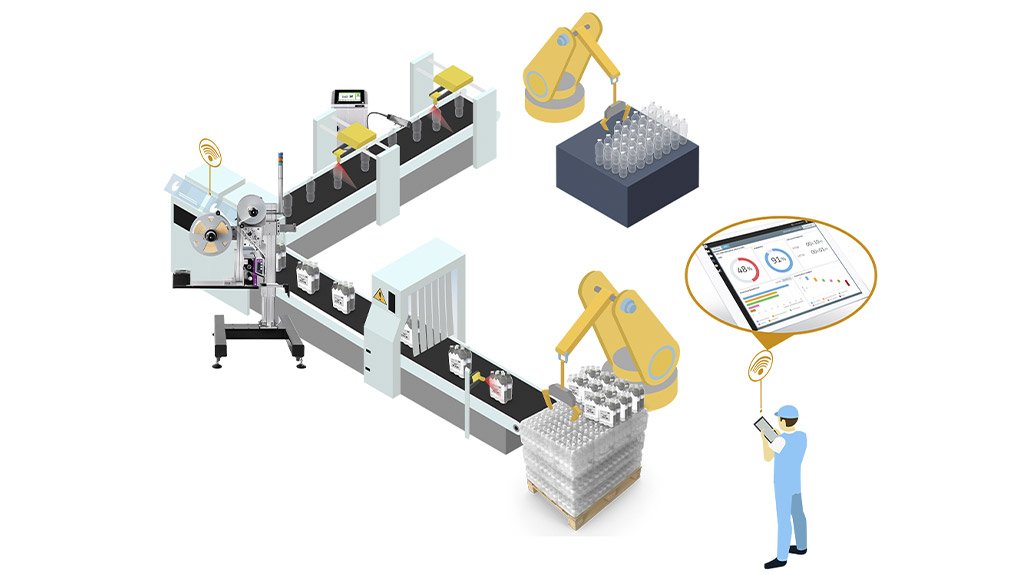

PackLink is designed to work with existing infrastructure. It integrates smoothly with leading ERP, MES, and WMS systems, making it easy to unify coding and packaging equipment into one connected network. This ensures better inventory accuracy and forecasting; real-time access to production data; reduced downtime and faster fault resolution; and smarter resource and waste management.

For South African beverage producers, this means streamlined operations from the filler to the palletiser, regardless of whether they are producing sparkling drinks, fruit juices, or flavoured water.

Secondly, PackLink enables accurate product Identification for every format. Inaccurate batch codes or expiration dates can lead to costly recalls and damage to a brand's reputation. PackLink’s advanced vision inspection and OCR technology ensure every beverage product is correctly identified, coded and verified.

By integrating automated print inspection into the line, PackLink reduces human error and maintains consistency across thousands of SKUs. In terms of getting the right label on the right drink, there is no room for a botched bottle ruining the prime production line.

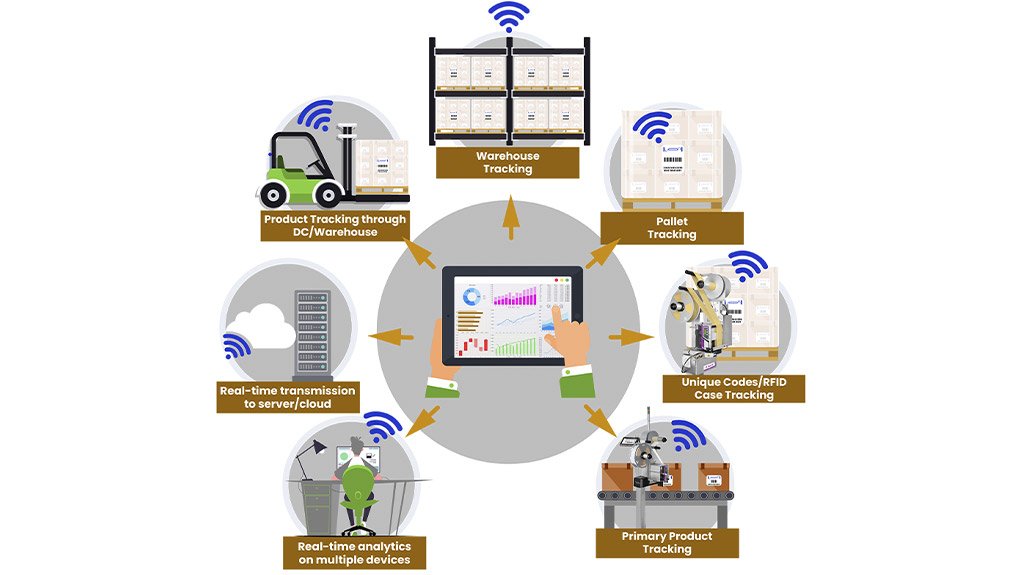

Additionally, PackLink enables full tracking and traceability from “bottle to pallet”. With serialisation, aggregation, and optional RFID/NFC tracking, PackLink products offer complete traceability across a beverage supply chain. From single-item coding to case and pallet aggregation, the software guarantees: End-to-end visibility; supply chain security and counterfeit prevention; compliance with export requirements; and faster, more targeted recalls.

This is especially important for beverage products exported from South Africa to regulated international markets, where full traceability is non-negotiable.

Finally, PackLink is built for South Africa’s beverage manufacturing environment. Regardless of whether a customer is operating a family-owned bottling plant or a multinational beverage facility in Gauteng, Cape Town or Durban, Pyrotec PackLink provides the tools needed to modernise their production environment without overhauling existing infrastructure.

With Pyrotec PackLink's trusted 24/7 support and locally available technicians, South African manufacturers can scale with confidence, knowing help is always close at hand.

PackLink Benefits

- Enhanced production line efficiency

- Real-time analytics and performance monitoring

- Reduced waste and increased Overall Equipment Effectiveness

- Compliant packaging for both local and export markets

- Improved inventory control with data-led forecasting

Pyrotec PackLink empowers South African beverage manufacturers to work smarter, not harder. Whether the customer is tracking thousands of units a day or building export-ready traceability, Pyrotec can help them connect their production and streamline their supply chain.

“Let’s turn your line from bottle-necked to bottle-going,” the company concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation