Hytec Group companies reduce OEM’s energy costs

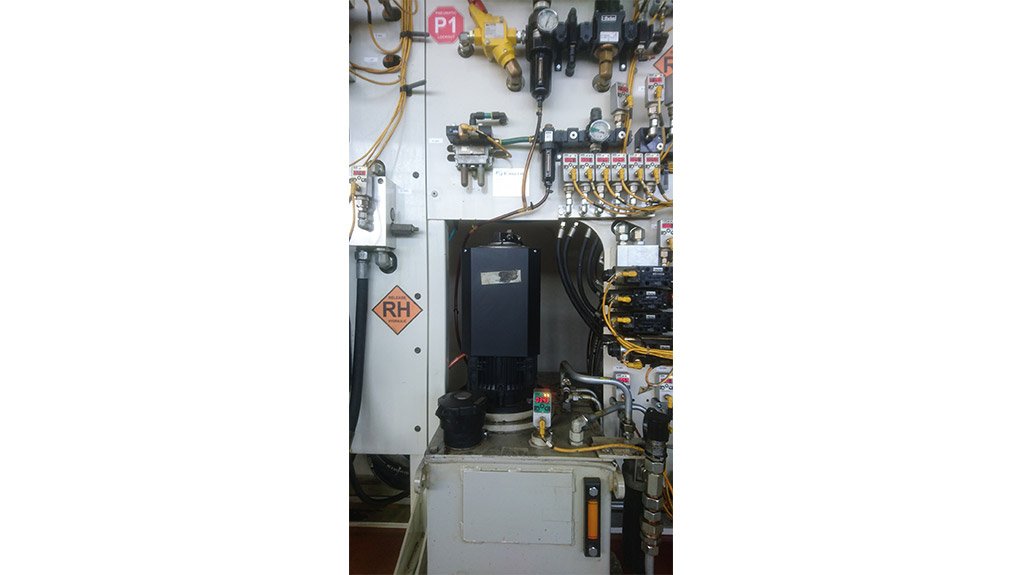

MONITORING PRESSURE The Sytronix variable speed pump drive monitors the hydraulic pressure and adjusts the motor running speed so only the required pressure at any given time is delivered

In a first for South Africa, automation solutions provider Tectra Automation and hydraulic solutions provider Hytec collaborated to aid a motor vehicle original-equipment manufacturer (OEM) reduce energy costs at its Port Elizabeth engine plant.

This was achieved with the installation of a Sytronix variable- speed pump drive in mid-2017, which has subsequently achieved a proven energy saving of 68% on the machine for which it was installed.

To reduce energy consumption, Sytronix, which monitors the hydraulic pressure and adjusts the motor running speed so only the required pressure at any given time is delivered, was installed at the plant’s block machining line. This was the first of kind for this specific OEM and for the Hytec Group.

Sytronix, a drive and control technologies group Bosch Rexroth product, is a smart interplay of hydraulics and electronics to generate hydraulic power on demand. It maintains the ideal motor speed without using more motor power than is necessary leading to energy efficiency and cost-cutting. Additionally, Sytronix reduces the noise levels from 72 dB(a) to 62 dB(a), almost half of that experienced on conventional power units.

As the unit is a combination of a hydraulic component and a drive and control component, both Hytec’s and Tectra Automation’s specialities were required for installation and commissioning.

“Sytronix has been available as a drive solution for some time now,” says Tectra Automation technical sales representative Adriaan Botes. “However, with the rise in electricity tariffs contributing to higher electricity costs, some companies are beginning to show an interest in this power-saving technology to reduce some of their overhead costs.”

Installation and commissioning was conducted over two days with Hytec installing the hydraulic components, drive and controls were installed by technical personnel from the OEM and overall commissioning was conducted by Tectra Automation.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation