Initial output from Sylvania Platinum’s new tailings project on track for first half of 2025

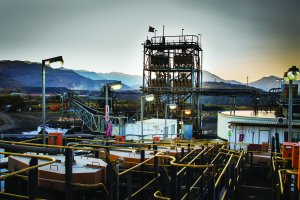

Sylvania's Doornbos plant.

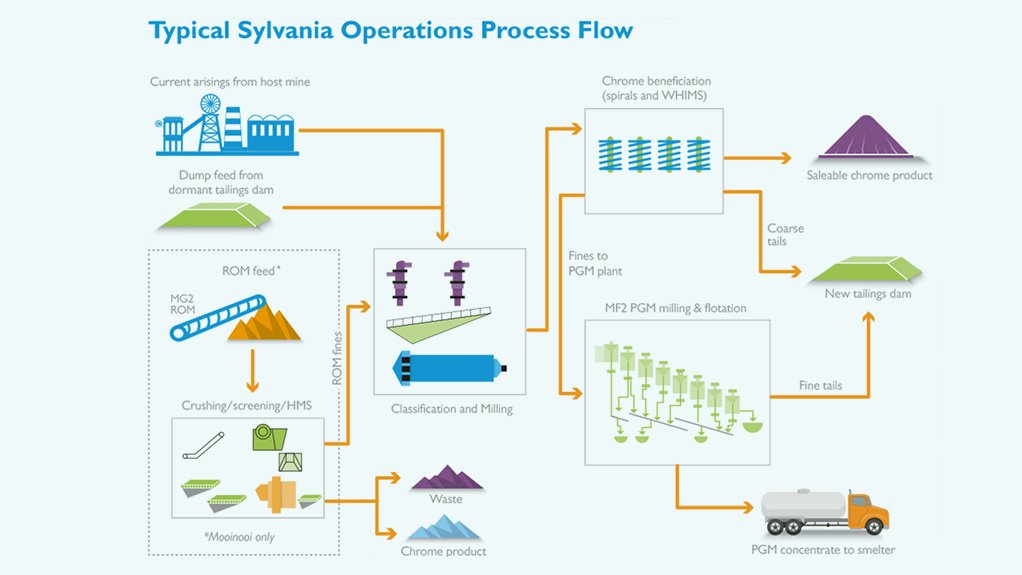

Sylvania's operational process.

Sylvania's Millsell plant.

Sylvania's Mooinooi PGMs flotation plant.

Sylvania's Doornbos plant.

Sylvania's Millsell plant

First production from the developing Thaba Joint Venture (JV) chrome and platinum group metals (PGMs) recovery project on the northern part of the western limb of South Africa’s well-endowed Bushveld Complex is expected in the first half of next year, the London Aim-listed Sylvania Platinum has said.

“The project will transform us into a significant chrome producer as we continue our examination of other opportunities,” Sylvania CEO Jaco Prinsloo highlighted in a fourth-quarter to June 30 report.

The JV is made up of PGMs producer Sylvania Platinum’s wholly owned South African subsidiary Sylvania Metals and ChromTech Mining Company subsidiary Limberg Mining Company and will process chrome and PGM ores from historical tailings dumps and current arisings within the Limberg chrome mine area.

On schedule are the design, procurement and construction elements of the project, which Prinsloo describes as respresenting the first stage of Sylvania’s strategy to diversify its production and income streams.

The 18- to 24-month execution of the provisionally budgeted R600-millon project came out of its starting blocks in August last year.

The Thaba JV is poised to advance Sylvania’s current core business retreatment of PGM-bearing chrome tailings in the six-plant Sylvania Dump Operations (SDO) in that a combination of run-of-mine (RoM) and historical chrome tailings will be treated, which will create a full margin chromite concentrate-revenue stream.

The group also holds mining rights for PGM projects on the Bushveld Complex’s northern limb, which take in the Volspruit, Aurora and Hacra projects. Results of the Volspruit project’s scoping study are expected this month.

In the three months to June 30, SDO recorded $20.6-million net revenue and earnings before interest, taxes, depreciation and amortisation of $2.8-million.

Cash of $97.8-million was on hand at the end of the period and SDO’s Doornbosch operation achieved 12 years lost-time injury-free days.

A half-year interim cash dividend amounting to $3.3-million was paid in April and a special dividend totalling the same amount was paid in June.

SDO’s Mooinooi and Millsell operations have reportedly stabilised after February’s mineworker strike and optimisation efforts continue to address lower PGM feed grades and recoveries associated with the blend of feed sources at selected operations.

The strike plus lower PGM feed grades and a decrease in associated metal recoveries related to the ore mix at some of the eastern operations resulted in a lower-than-anticipated quarterly production and ultimate yearly production of 72 704 platinum, palladium, rhodium and gold (4E) ounces for the full 2024 financial year, which was below the target of between 74 000 and75 000 4E PGM ounces for the year.

The capital expenditure incurred of R98.2-million is in line with planned capital project schedules.

Optimisation of ore blending remains a priority with continuing focus on improving equipment runtime, which has resulted in an increase of 2% in flotation plant throughput.

A feasibility study for a potential new treatment facility for chrome tailings and RoMore sources at the eastern operations is in progress.ro

At Lesedi, Section 189A labour relations consultations are under way on the possible restructuring of the operation.

PGM Plant Progress

Civil works for the PGM plant are complete and steel erection has commenced. The first batch of float tanks has been installed and fabrication of the reagent plant is under way.

Orders for long-lead infrastructure have been placed and most of the electrical, control and instrument design work has been completed, with small power, lighting and the last of the non-critical instrument datasheets being undertaken.

Preparation works have started for the equipping of strategic boreholes and opencast pit dewatering and recovery to supply clean water to the plant. The stormwater management design was completed and simplified. Enquiries have been issued for the construction of the tailings storage facility for in-pit deposition.

Construction of the new in-plant road for PGM and chrome concentrate truck dispatches is in progress.

Volspruit Project

The scoping study being finalised by SRK Consulting was undertaken to assess the Volspruit project’s economic viability based on the updated mineral resource statement that was published earlier this year.

Contributions from rhodium and the additional resources from the south orebody are now included as well as updated input costs.

Additional metallurgical testwork has also been completed at Mintek South Africa on samples obtained during drilling with the final report expected early next year.

The updated results from the scoping study and metallurgical testwork will be used to guide Volspruit’s next steps.

Far Northern Limb Projects

An exploration programme for Aurora has been compiled based on the reinterpretation of historical drilling.

A geophysical survey has been proposed to cover the entire strike length of the project to assess both the continuity of the mineralisation as well as to gain a greater understanding of the structural setting of the area.

The Hacra project area will be included in the geophysical survey ensuring that knowledge gained from the work covers the entire project area.

A technical report on the Hacra north underground target from independent consultant Earthlab Technical Division is under review and will form part of an exploration update announcement this month.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation