Italian pump manufacturer orders Vesconite Hilube components following successful BEP testing

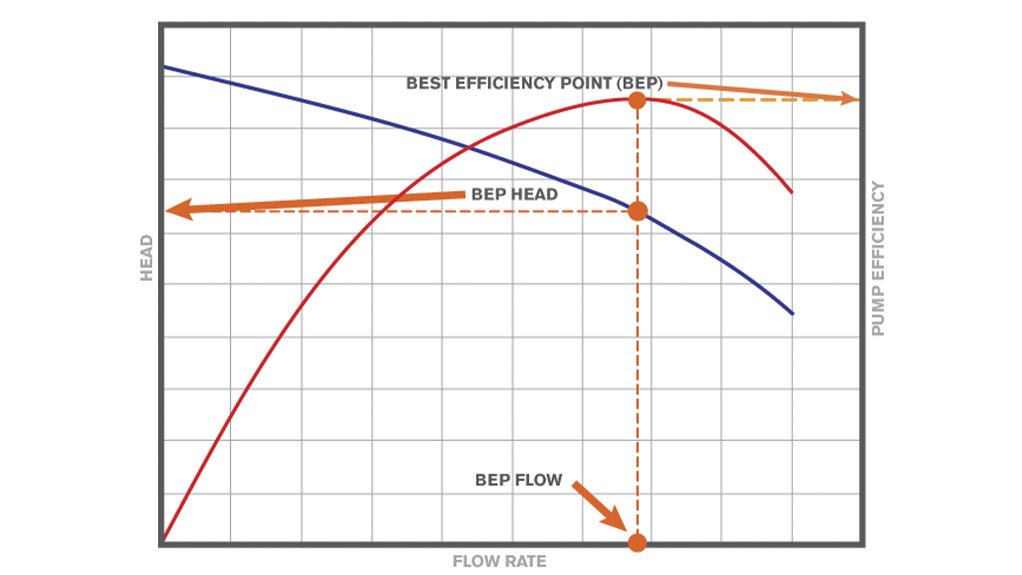

The Best Efficiency Point describes the flow rate and head conditions at which a pump operates with maximum efficiency

This article has been supplied.

An Italian pump manufacturer has ordered Vesconite Hilube line shaft bushings following a successful efficiency test conducted at its pump’s Best Efficiency Point (BEP). The manufacturer incorporated Vesconite Hilube bushings into one of its submersible pump designs and tested a pump continuously for 40 hours at its most efficient operating point.

While the exact efficiency percentage, flow rate, and head achieved during the BEP test were not disclosed, the manufacturer reported positive outcomes and confirmed that the Vesconite Hilube bushings showed no signs of wear or scratching after prolonged operation. The favourable performance has led to further procurement of the tested line shaft bushing model, along with other Vesconite Hilube pump components.

The BEP describes the flow rate and head conditions at which a pump operates with maximum efficiency. It is a key indicator in pump performance testing, widely used to verify design accuracy and provide product specifications for pump users. Operating a pump at or near its BEP can minimise energy consumption, reduce component wear, and extend overall equipment life.

While pump bushings do not change the hydraulic BEP itself, they play a key role in helping the pump maintain its designed performance curve over time by reducing shaft deflection, vibration, and internal leakage, especially as components wear.

“Vesconite Hilube’s ability to reduce the clearance between the bushing and the shaft sleeve can benefit the hydraulic performance of the pump,” says Tristen Wintershoven, an application engineer at Vesconite Bearings.

“By decreasing the clearance, you can reduce excessive shaft movement and vibrations. This can lead to more stable pump operation, since excessive shaft motion can cause misalignment, wear, and energy losses.”

In pumping applications, the stability of the shaft is critical to performance. Excessive movement, often the result of loose clearances in shaft-bushing interfaces, can cause internal leakage and misalignments that impair hydraulic efficiency. Bushings that allow for tighter clearances (such as those manufactured from Vesconite Hilube) support shaft stability and improve overall fluid handling.

“If the clearance is too large, it can lead to internal leakage, causing a loss of energy efficiency and potentially reducing pump performance,” explains Wintershoven. “By reducing the clearance, you may reduce this leakage, improving overall hydraulic efficiency.”

Vesconite Hilube has been successfully used in various pump types, including vertical turbine and submersible designs, due to its self-lubricating properties, low water absorption, and high dimensional stability. These characteristics make the bushing material especially suitable for submerged and semi-submerged applications where conventional bearing materials may swell or degrade.

In this recent application, the material’s durability was a focal point of the BEP test. After 40 hours of continuous operation, the pump manufacturer noted no scratching or degradation on the Vesconite Hilube bushings—underscoring the material’s resistance to wear even under sustained optimal performance conditions.

The manufacturer’s confidence in Vesconite Hilube’s performance has also led to it ordering additional pump components that were not part of the BEP testing. The decision to continue specifying Vesconite Hilube components is consistent with a broader industry trend prioritising pump efficiency and operational resilience.

As energy consumption becomes a critical cost and sustainability factor in water handling and industrial processes, attention is increasingly turning to components that can deliver incremental performance improvements.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation