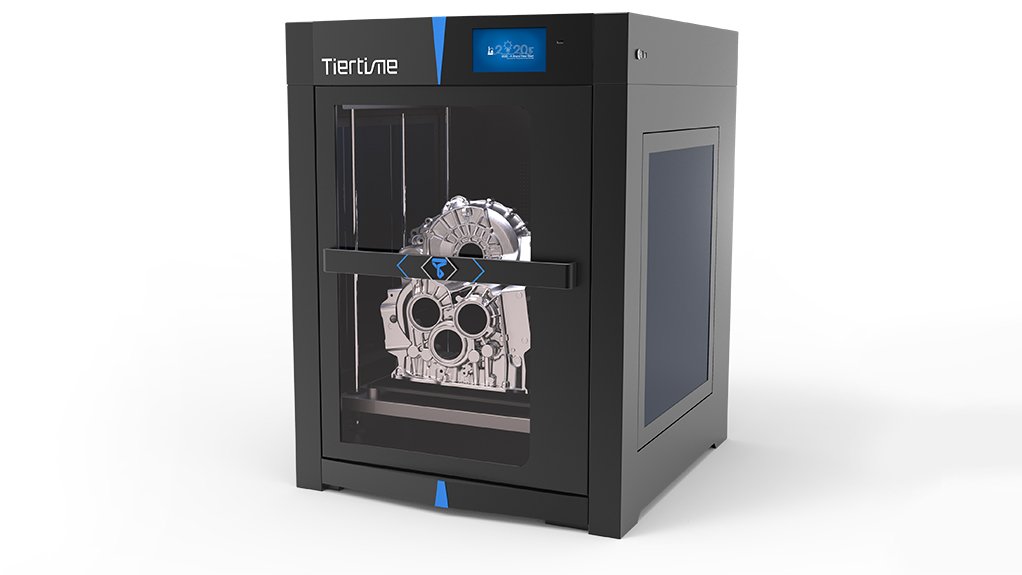

Large Format 3D Printer for a variety of jobs

A three-dimensional (3D) printer designed for very large jobs in application areas such as engineering, prototyping, short-run production, one-off fabrication, large-scale modelling, medical research and development, education, prop manufacturing, architecture, and industrial tooling is said to offer exceptional printing quality.

The Tiertime UP600 factory built and fully enclosed large 3D printer from 3D Printing Systems SA offers industrial quality 3D printing and large print volumes of up to 400 mm x 500 mm x 600 mm.

With its thermostatically controlled heated build chamber, the UP600 printer can use a variety of print heads – single and dual, offering versatility in printing all types of thermoplastic filaments. The machine also features a flexible printing plate that magnetically attaches to the printing bed for easy removal of printed outputs.

The Tiertime UP600 includes the following features:

- Large print volume 400 mm x 500 mm x 600 mm - 10 times as large as

- that of the UP300.

- Heated build chamber helps to minimise deformation caused by high temperature plastic cooling too quickly and absorbing naturally-occurring airborne moisture in the process.

- Embedded air filtration system - filters air through HEPA filters and activated carbon filters which help to reduce toxic emissions. HEPA filters promise 99.95% efficient filtration for ultrafine particles.

- Wi-Fi, ethernet, and USB connections, allowing multiple users on a network to send tasks to the printer, which can be monitored and managed using the Tiertime print queue.

- UP Studio 3.0 is a dedicated software package and slicing engine developed for Tiertime machines. It supports both dual and single material printing and offers granular print parameter control. Within a single print job, multiple models can be printed with different settings and each model can have designated sections with their own settings.

The industrial 3D printer is designed to enable the printing of very large parts in one go, reducing post-production assembly needs.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation