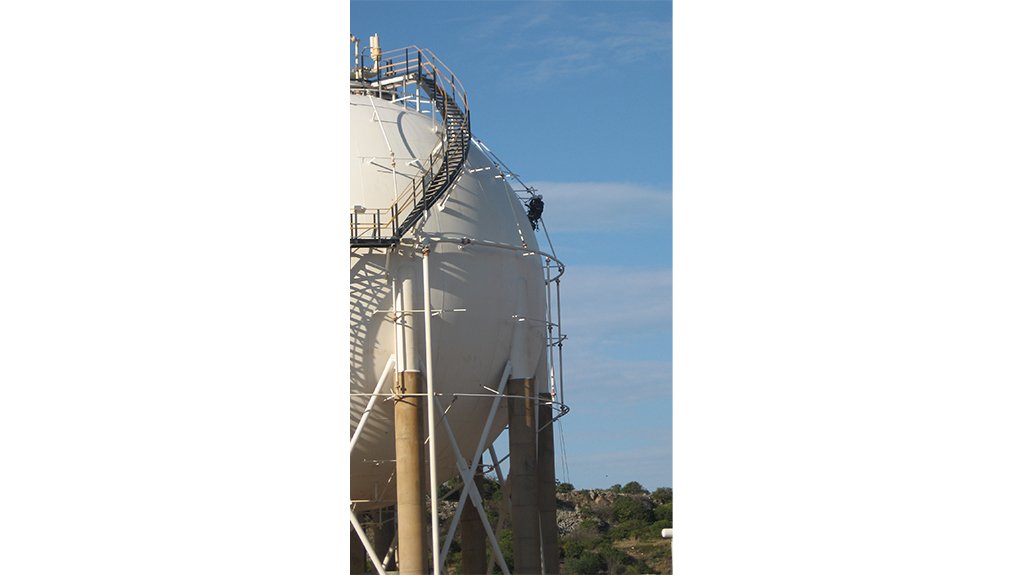

Project completed using rope access

SAFELY SOARING Rope access was deemed the safest option, as the fireproofing was not stable enough to allow for other more traditional means of access to get close to the gas storage tank

Rope access specialist Skyriders completed the removal of a layer of cementitious fireproofing and insulating material from a spherical gas storage tank at a petrochemicals producer, in Mpumalanga, during the first quarter of 2020.

The material became compromised, as it was nearing the end of its serviceable life span, and Skyriders had to remove the materials so that a replacement could be made.

Working systematically from top to bottom, the Skyriders rope access team successfully cut and removed the cementitious fireproofing using an ultra high-pressure blaster supplied by water jetting company Total Site Solutions, says Skyriders marketing manager Mike Zinn.

He explains that, rope access was deemed a safer option, as the fireproofing was not stable enough to allow for other more traditional means of access to get close to the gas storage tank.

“Removing the fireproofing and insulation would not have been possible with scaffolding, as people working below the tank would have been placed in danger.

”

He tells Engineering News that the fire safety deluge system needed to be removed prior to the removal of the fireproofing material. Rope access was also used during this initial part of the project.

After the materials had been removed, another vendor installed new fireproofing.

“This was a big project in terms of magnitude, with the gas storage tank towering at 22 m high and 19 m wide.”

While the ultra high-pressure blaster did not need to be adapted or modified for this project, Zinn says extra safety precautions needed to be put in place.

The ultra high-pressure blaster, which uses water, was the best tool to use for this project. “With the extremely explosive nature of the environment within the gas storage tank, we needed to completely eliminate the risk of using grinders or any other tool that could possible cause a spark. The blaster provided our team with the best solution.”

High-pressure blasting can be extremely dangerous and can cause significant damage to property and serious injury to a person, Zinn points out. “The onus is on us to ensure that the person handling the equipment has the correct training and competencies as well as full personal protective equipment (PPE). In addition to the standard PPE that our rope access team uses, the person handling the blaster uses additional PPE that was purchased from an ultra high-pressure blaster supplier.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation