New mining technology is pointing to continuous round-the-clock operation on many fronts

Master Drilling presentation covered by Mining Weekly's Martin Creamer. Video: Darlene Creamer.

Master Drilling director Koos Jordaan.

Photo by Creamer Media

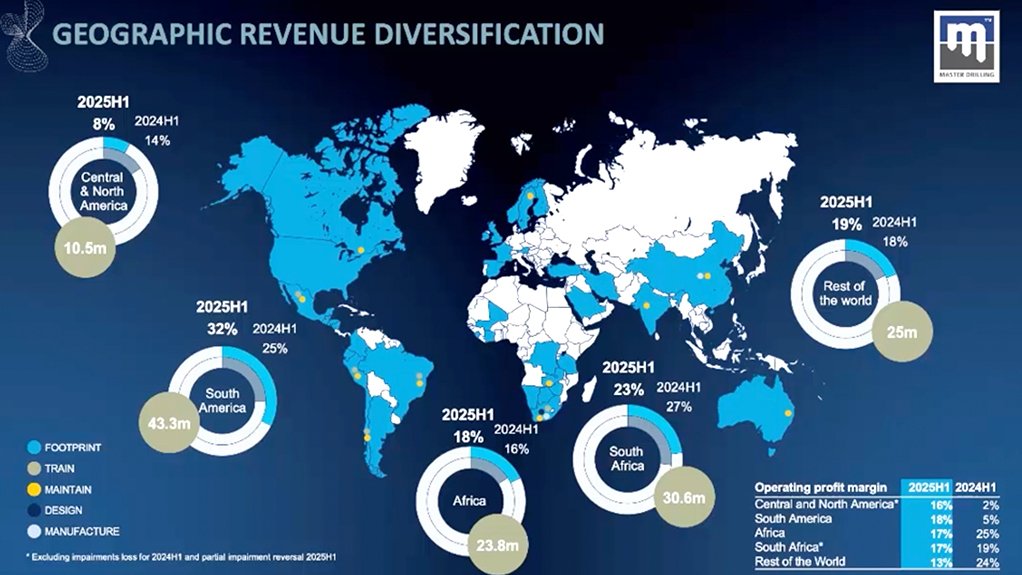

South Africa's Master drilling on all continents.

Shaft boring system.

JOHANNESBURG (miningweekly.com) – The new mining technology being advanced by Master Drilling promises “continuous”, round-the-clock mining uplift – even when it comes to narrow reef extraction.

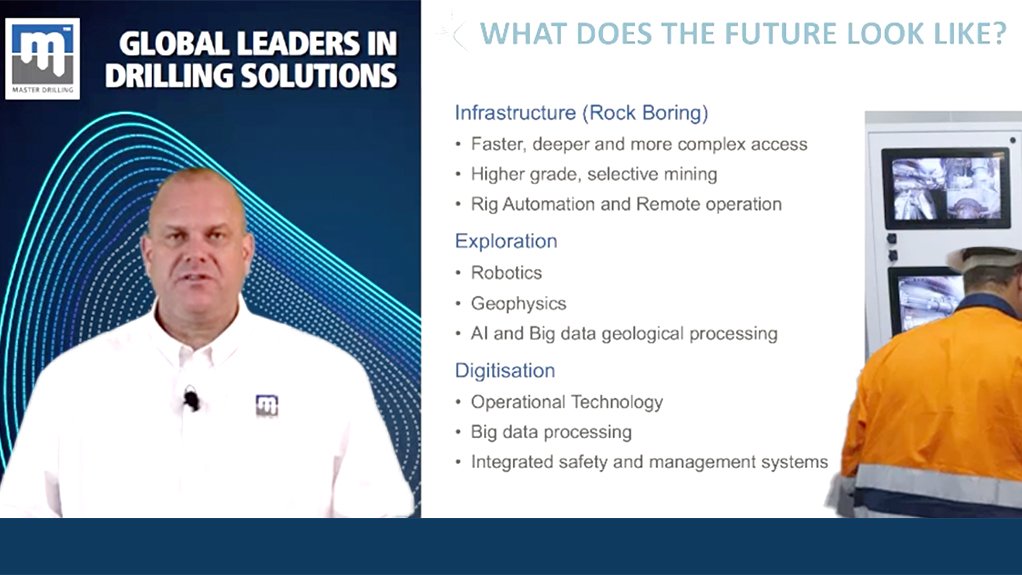

On the new technology being developed, Master Drilling director Koos Jordaan displayed a slide that repeated the three words “continuous rock excavation” three times over, whether for shaft sinking, tunnelling or reef boring – and precise reef boring with minimum dilution, to boot.

Popping up repeatedly as well during this Johannesburg Stock Exchange-listed company’s presentation of 399%-higher half-year after-tax profit of $18.1-million was the repeated use of the words “automation, remote operation, robotics, digitisation, artificial intelligence (AI), and virtual reality." (Also watch attached Creamer Media video.)

Encouragingly, project after project came with the word “complete”, to indicate that the main work needed is already done and dusted.

To prove this were pictures of real rigs, real tunnel borers, real reef borers – and even real screen grabs, one of which showed the daily tracking by Master Drillings’ safety technology subsidiary A&R of about 75 000 people underground, which gives an idea of the volume of data collected, reported, stored, analysed and AI-augmented, to provide clients with ongoing resource management.

“I think it's safe to say that the world is changing faster and we're looking at how and where we should position ourselves to be relevant and sustainable,” added Jordaan during the presentation covered by Mining Weekly.

“In the short term, we’re setting up and developing our capability in terms of shaft sinking, tunnelling, reef boring, where we want to offer a solution for quicker underground access. We're also working on solutions to do selective mining, providing higher grade for clients. Then also rig automisation and remote operation,” Jordaan reported.

A significant amount of operation would, he explained, be done in an autonomous, remote manner to enable safe and efficient performance.

Regarding exploration, investment has been made into the development of robotics for materials handling for underground and surface core drilling projects. This is also applicable to projects where remote operation is required in opencast mines for delineation, grade control, reverse circulation, and percussion pre-drilling. Outlined was also the role that geophysics could play in gathering data quicker, easier.

The use of AI to make information available quickly was emphasised, with digitisation creating an operational technology platform on which all big data was collectable, processable and integrated to uplift dispatch and everything else.

Technology development and trends around the globe are continuing to be monitored by this Proudly South African drilling and mechanised rock excavation technology company that operates in 28 countries across five continents.

Regarding raiseboring, which represents 80% of the business, factory acceptance testing has been done for the Bluebot rig, and two of the three large capacity RD6 DC low-profile raise-bore rigs manufactured have been deployed to operations.

In addition, a second-generation design for the mobile, smaller capacity slot boring LP 100 rig is scheduled for completion by the beginning of 2026.

In slim drilling, the surface concept validation, testing and commissioning of a surface robotic core drilling rig has been completed, making it available for further field trials.

The experimental sinking of a shaft was completed at the beginning of this year to get down deeper much faster. Funding is being reviewed and design work done on the next phase, for testing during the first half of next year. In parallel, market engagement is taking place for the pursuit of commercial projects for this service.

In tunnelling, a contract for the mobile tunnel borer (MTB) has been secured as commissioning is finalised ahead of on-site mobilisation in the next few weeks. Most of this work will take place during 2026 at the Bokoni platinum group metals mine in Limpopo, which is run by African Rainbow Minerals, for which development of non-explosive reef boring technology is ongoing.

“We're doing further testing and validation work on surface in our yard and then towards the end of the year, that resource will do its first field trial during the first half of next year,” Jordaan informed the half-year results presentation attendees, which included Mining Weekly.

In digitisation, A&R has installed two winch proximity systems for two different clients, which enable a level 9 collision avoidance operation, the mining industry’s highest standard of collision awareness.

“There’s huge market potential and application potential for the winch proximity systems considering the risk in stopes,” Jordaan commented.

A&R is also testing a communication system, a tool for data transfer from the mining phase to a kilometre beyond.

Testing is also being done on an AI camera mounted on a locomotive, which recognises collision danger and automatically retards movement.

The testing of shift clearance and missing person location that is under way is expected to cut the time required for re-entry, potentially reducing three hours lost to only one hour lost.

Master Drilling’s stake in Applied Vehicle Analysis, better known as AVA, is also being used for algorithm development for underground application and dispatch.

Displaying the image of an RD 6 DC low-profile raiseboring rig, Jordaan said: “It's a large capacity rig. It's very mobile, and it requires a very low headroom underground, so it's a very competitive tool.”

Highlighted pictorially as well was the Bluebot rig for larger slots, remote operation and autonomous control.

A shaft-sinking image displayed experimental sites where testing for the shaft boring system (SBS) was done and more on-site testing will be done during the first half of next year. The next SBS iteration will feature a larger diameter and productivity of 5 m to 10 m a day is envisaged. “We’re very confident on this project and very excited about it,” said an upbeat Jordaan.

Put on view below shaft collar was the Bluebot rig’s reworked configuration for a larger diameter, greater flexibility and targeted productivity of around 5 m to 10 m day, with an ability to reach underground orebodies quicker.

The MTB to be mobilised on contract in the next few weeks was displayed being commissioned in Master Drilling’s yard involving testing on a concrete block. “We don't need, like conventional tunnel boring machines, a pre-launch excavation.

“We do it from a starter frame. It's modular to position it. We don't need a gallery with cranes to assemble it. We can basically drive it off abnormal loads and assemble the machine in a fraction of the time with a fraction of the people. This is an initiative from ourselves to provide a solution to the industry for quick and safe access to orebodies in a near horizontal orientation.”

The SBS eliminates the need for conventional blasting in hard rock material; the MTB is destined to tunnel for some distance at the Bokoni platinum mine; and the third is a narrow reef cutting advance with the likely ability to halve the development of a mine, for example ensure that what would conventionally be a 600 000 t mine into a 300 000 t mine – but with the same number of ounces produced.

Currently inaccessible narrow-reef upper group two (UG2) reef at Bokoni is the target of the twin MTB and narrow reef cutter. Tunnelling will be done with the MTB for some distance, and then on-reef cutting will follow. The reef-boring machine was shown being tested on artificial UG2 reef.

“This is to perform selective mining and improve the grade of what's being mined. This in conjunction with a mobile tunnel borer could potentially establish a hard rock mining operation that's non-explosive and continuous. There are huge opportunities in terms of the concept around this,” Jordaan pointed out.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation