New steel and heat treatment raises performance of bearings in wind turbine gearboxes

This article has been supplied.

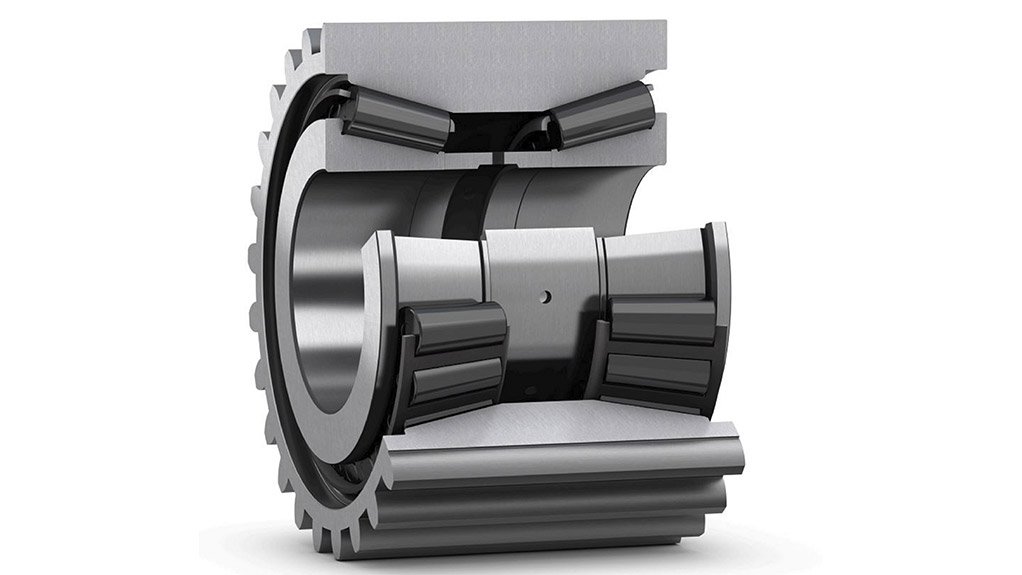

The SKF high durability gearbox bearing for wind raises the torque density in wind turbine gearboxes by reducing bearing and gear size up to 25% through an improved rating life while at the same time avoiding premature failures through improved robustness.

SKF has developed a new roller bearing for wind turbine gearboxes that offers bearing rating life at the forefront of the industry and enables reduction of downtime and maintenance.

The SKF high durability gearbox bearing for wind relies on a tailored combination of steel and heat treatment process that is developed to raise fatigue resistance and robustness. A thermochemical heat treatment process improves its surface and subsurface properties.

“The heat treatment process enriches the surface layer of the bearing components and improves the material strength both at and below the surface, covering the high stressed material volume during bearing operation”, says David Vaes, manager of the Wind Gearbox Competence Centre at SKF. “Rolling bearing performance very much depends on material parameters such as microstructure, residual stress and hardness.”

This tailored steel and heat treatment process has several benefits: it increases bearing rating life and enables downsizing; and increases the new bearings capacity to resists typical failure modes in gearboxes, such as premature failures related to White Etching Cracks (WECs), micropitting and wear.

Internal tests and calculations show up to a fivefold increase in bearing life compared to current industry standard. Moreover, an up to 10-times higher robustness against stress induced premature failures with WECs have been proven on inhouse test rigs.

The improved performance of SKF high durability gearbox bearings mean the bearings can be downsized, helping to increase torque density of the gearbox. This is critical in the latest generation of multi-megawatt turbines.

In a typical planetary stage of a 6MW wind turbine gearbox, a size reduction of the planet wheel bearing of up to 25 %, and consequently of the planet gear as well, is achievable by using SKF high durability gearbox bearing while keeping the same rating life as the industry standard bearing.

Similar size reductions can be achieved on different positions in the gearbox. In a parallel gear stage, the bearing size reduction will also reduce the risk of slip-related damages.

Resistance to typical failure modes could help gearbox manufacturers, turbine owners and service providers to increase reliability and have less unplanned turbine standstill and repair cost.

The new features helps to reduce the Levelized Cost of Energy (LCoE) for wind and supports the wind industry journey to become a cornerstone in the future energy mix.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation