New technology bolsters fight against greenhouse-gas emissions

Managing emissions while ensuring optimum production is a constant challenge for industries and has become even more pertinent with the introduction of new South African legislation requiring existing plants to comply with minimum emission standards of nitrogen oxide (NOx) levels limited to less than 350 mg/Nm3.

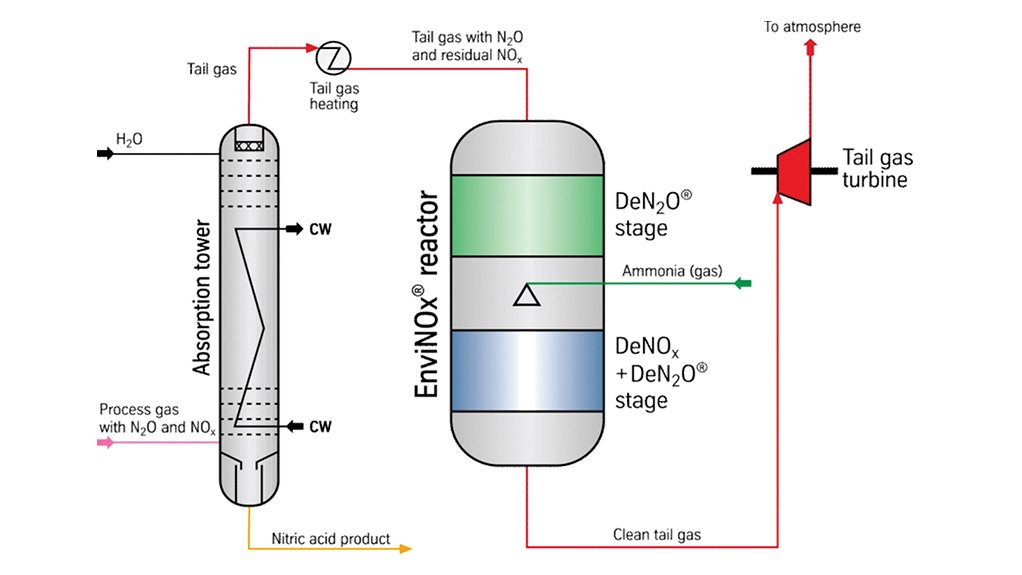

thyssenkrupp Uhde says that its EnviNOx technology is capable of almost completely removing NOx and the greenhouse gas nitrous oxide (N2O), turning it into harmless nitrogen and water. N2O is produced as a by-product in the manufacture of nitric acid, an important raw material used in the production of fertilizers, amongst others.

The company says its technology has been proven on an industrial scale with about 55 plants using the process worldwide and four systems sold in South Africa. thyssenkrupp Uhde is also the licensor of the nitric acid process for five of the six nitric acid plants in South Africa.

EnviNOx removes NOx through a process similar to what is used to reduce emissions in automotive vehicles, namely selective catalytic reduction (SCR) which uses a catalyst and a small amount of ammonia in the reaction process.

While SCR technology is already used by several suppliers, thyssenkrupp explains that it has successfully developed a reactor and catalysts specifically for the abatement of both N2O and NOx in nitric acid plant tail gas. “The N2O and NOx removal rates of our EnviNOx technology, which was developed in Germany in the early 2000s, have been proven commercially to be very high, achieving N2O removal of up to 99%, and NOx emissions to nearly zero,” states thyssenkrupp business development manager Nithesh Mohun.

The central component of the system is the reactor, which contains a special catalyst usually located between the final tail gas heater and the tail gas turbine. There are two process variants, with one especially applicable for tail gas temperatures higher than 425 °C while the second variant is suitable for temperatures between 300 °C and 550 °C.

The combination of N2O and NOx emissions reduction in a single reactor vessel makes the EnviNOx system particularly flexible as it provides end-users with the option of initially investing in NOx reduction only, with an option to upgrade to N2O abatement at a later stage.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation