Organisation positions motor efficiency as key deliverable

FANIE STEYN The adoption of variable-speed drives has increased from about 5% of applications in the past, to between 30% and 50% in mining operations, of late

REDUCED OPERATING COSTS Lower energy use, combined with a lower maintenance requirement, results in substantial operating cost savings

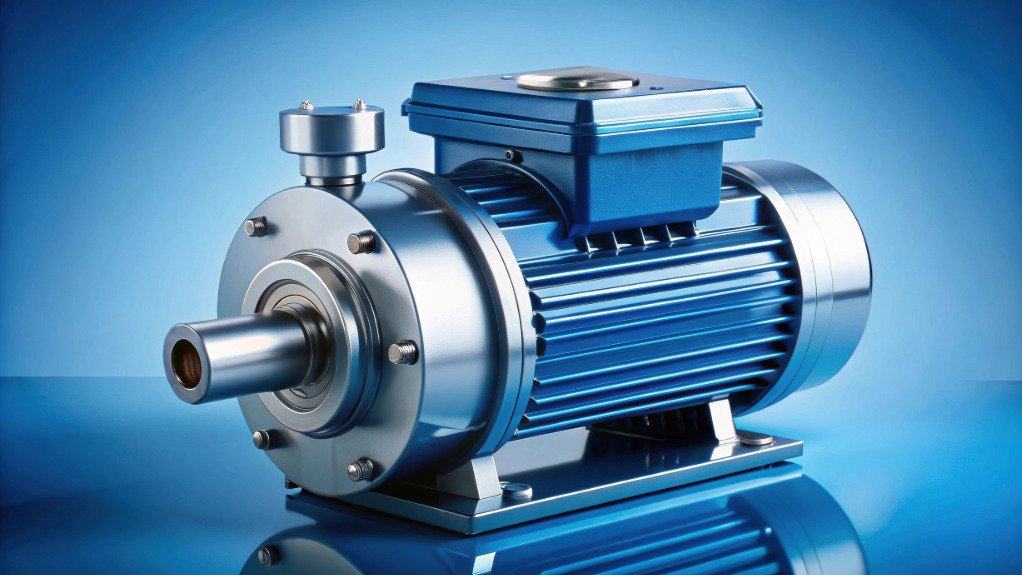

Electric motors are central to South Africa’s mining operations – powering fans, pumps, conveyors and other essential equipment – making developments in motor and drive technology increasingly more important, highlights industry organisation South African Institute of Electrical Engineers (SAIEE) rotating machines section (RMS) chairperson Fanie Steyn.

Mining – having to deal with challenges, such as energy constraints and having to extract lower-grade ore more efficiently – forms a big part of the end-user segment in South Africa, as motors comprises about 60% of the electrical consumption of a mine.

Therefore, it is important to integrate new technological developments for motors and drives into mining operations, with recent advances, such as (IE4) motors, variable-speed drives (VSDs) and the integration of AI and machine learning for predictive maintenance, he adds.

“VSDs, in particular, are being applied to centrifugal pumps, fans, compressors and conveyors to adjust speed according to process demand. This allows operators to reduce energy consumption while maintaining process output.”

Steyn also notes that the adoption of VSDs has increased from about 5% of applications in the past, to between 30% and 50% in mining operations, of late.

In mechanically controlled processes, VSDs replace flow-reducing valves and other devices, allowing for precise speed control and energy savings, notes SAIEE RMS represenative Ruveer Persad.

VSDs also reduce energy spikes during startup, lowering strain on South Africa’s electricity grid, which remains an important consideration amid the country’s energy constraints.

While energy savings are important, Persad says the primary driver is process control, as the VSD allows for operations to run more smoothly, with energy efficiency being a beneficial outcome of that control.

Technological Considerations, Sustainability Objectives

AI and machine learning are being integrated into the operation and maintenance of motors through smart sensors which monitor temperature, vibration, running hours and other operational parameters.

Data from these sensors is analysed to predict potential failures, allowing for maintenance to be scheduled before equipment breakdowns occur.

“AI forces you to be proactive rather than reactive. It is now becoming an era of predictive maintenance rather than actual maintenance, allowing operators to act before downtime affects the plant,” says Steyn.

Persad notes that efficient motors and drives also contribute to sustainability, adding that reduced electricity consumption directly lowers CO2 emissions, which is particularly significant in South Africa, where coal-fired power stations remain the primary electricity-generation method.

Electrification and using energy efficient equipment are, therefore, essential to reducing the environmental footprint of mining operations, says Persad.

For new mining projects, Steyn highlights the importance of installing high-efficiency motors from the outset, while in existing operations, replacing older motors and upgrading mechanical control systems with VSDs can deliver energy and cost savings.

He adds that durability, ease of maintenance and availability of spare parts are important considerations when implementing these technologies.

With end-users increasingly standardising motor and drive combinations from a supplier, simplifying maintenance and support, the adoption of IE4 motors, which exceed current IE3 regulatory requirements, is becoming more common, particularly in applications requiring continuous operation.

“Many of our mines have grasped the concept of energy efficiency in the prime mover’s electric motors, and are already installed with IE4 motors. These machines operate continuously and their impact on energy stability, operational efficiency and sustainability is significant,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation