Platinum metals could end up in both electric car technologies – BEV and FCEV

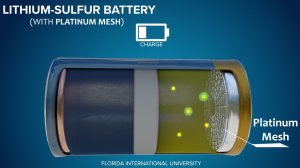

Platinum mesh added to lithium-sulphur batteries.

Florida International University developing platinum inclusion.

Frank Hallam.

JOHANNESBURG (miningweekly.com) – Platinum is already very well embedded as an indispensable catalyst in the hydrogen fuel cell electric vehicle (FCEV) technology that very impressively powered the Toyotas that chauffeured delegates during last week’s B20 and G20 global summits in Johannesburg.

Now, the precious metal that South Africa hosts in greater abundance than any other country on earth could also find that its remarkable catalytic qualities are utilised by battery electric vehicles (BEVs) as well.

This is because platinum group metals (PGMs) have been found by Florida International University to be able to extend the life of lithium-sulphur batteries for the betterment of not only sustainable mobility but also for renewable-energy storage, and to have potential to be a significant efficiency and sustainability boost for electricity grids as well.

New York- and Toronto-listed Platinum Group Metals Limited reiterates this in its latest 2025 annual results, in which the Canada-based company makes clear that it is continuing to advance the use of PGMs in lithium battery technologies by way of Lion Battery Technologies, which is highlighting the benefits that PGMs can bring to the lithium battery space.

Interestingly, Platinum Group Metals Limited spelt out in a media release to Mining Weekly that it is also continuing to take the Waterberg project on the northern limb of South Africa’s PGM-rich Bushveld Complex in Limpopo province towards a development and construction decision.

While this is underway, the company, headed by CEO Frank Hallam, is continuing to collaborate with an affiliate of South Africa’s Johannesburg Stock Exchange-listed Valterra Platinum and Florida International University to take PGMs to the next level. Valterra, it should be noted, is the company that last week chauffeured B20 and G20 delegates around Johannesburg in Toyota Mirai cars, which are FCEVs.

Valterra led a mine-to-market FCEV display, which involved South Africa's Sasol providing the hydrogen, Air Products dispensing the hydrogen, Bambili Energy providing the South Africa-manufactured membrane electrode assemblies for the fuel cells, and Bosch, providing the fuel cells.

On top of this, it is envisaged that the use of PGMs in BEVs will be achieved by allowing the catalytic contribution of PGMs to extend the life of lithium-sulphur batteries significantly, through the addition of nanoparticles of platinum to the sulphur side of the battery so that the tiny particles can work at molecular scale to ensure a cleaner, greener and healthier tomorrow.

This comes against the background of diversified demand for PGMs having already extended well beyond the automotive, jewellery, investment, and hydrogen sectors into the fibreglass, semiconductor, health and even food preservation sectors in what many see as “only the beginning”.

Interestingly, research and development by Florida International University is repeatedly pointing to the lighter weight and higher energy density of lithium-sulphur batteries as important competitive advantages engendered by PGMs.

“The unique properties of PGMs as powerful catalysts are being applied to various technologies as possible solutions for more efficient energy generation and storage, which may create new demand for PGMs.

“The company's battery technology initiative through Lion with partner Valterra represents one such new opportunity in the high-profile lithium battery research and innovation field,” Platinum Group Metals Limited stated, while also pointing out that the investment is creating a vertical integration with a broader industrial market development strategy to bring new PGM-using technologies to market.

Lion’s reiterated target is to develop batteries with specific energies that are 20% to 100% higher than current technologies while meeting or exceeding their present cycle lives though the unlocking of chemistries for use in BEVs.

As reported by Mining Weekly, Lion has engaged the Battery Innovation Center in Newberry, Indiana, to help accelerate commercialisation efforts for its next-generation PGM-enhanced battery chemistries.

The Battery Innovation Center’s scope of work is to conduct independent small- and large-scale trials to validate Lion’s proprietary PGM-based electrode composition, slurry, and films in lithium sulphur cells.

There is little doubt that PGMs will provide BEVs with additional kilowatt hours per kilogram. Catalysts based on PGM nanoparticles offer a potentially rapid solution to many of the current battery problems and have been shown to improve the performance of the batteries.

WATERBERG PROJECT

The Waterberg project is being planned as a mechanised, shallow, decline access palladium, platinum, gold and rhodium, or four-element, mine. Platinum Group Metals Limited is the operator of the project, as directed by a technical committee also including representatives from joint venture partners Implats, Mnombo, and HJ Platinum Metals. The Japan Organisation for Metals and Energy Security has established the special purpose company, HJ Platinum Metals, to hold and fund their future equity interests in the Waterberg project.

Being assessed are commercial alternatives for mine development financing and concentrate offtake.

As a part of the investigation of smelting and base metal refining options, discussions with all South African integrated producers, including Implats, are taking place, with a view to negotiating formal concentrate offtake arrangements.

To date no terms have been agreed and as an alternative, the possible establishment of smelting and base metal refining facilities in either Saudi Arabia or South Africa is still being studied.

“Before any processing of materials in Saudi Arabia could occur, South African government authorisation for the export of concentrate or matte would be required,” the company restated in the latest report.

In September, the board approved a sixth stage of work in the amount of R92.1-million for fiscal year 2026 to allow for the continuation of work programmes underway.

The interim budget, which covers the period to the end of August next year, includes components of a $21-million pre-construction work programme approved in principle for the Waterberg project.

During the fiscal year to August 31, a net loss of $4.54-million was incurred. General and administrative expenses during the period were $3.66-million. Share based compensation was $1.19-million. The foreign exchange gain recognised in the current period was $95 000, well up on last year’s $4 000 owing mainly to the US dollar increasing in value over the Canadian dollar during the financial year.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation