Power your industrial equipment for optimal productivity

This article has been supplied.

Investing in reliable batteries and chargers for industrial equipment is a strategic decision aimed at enhancing productivity, safety, cost-efficiency and environmental responsibility.

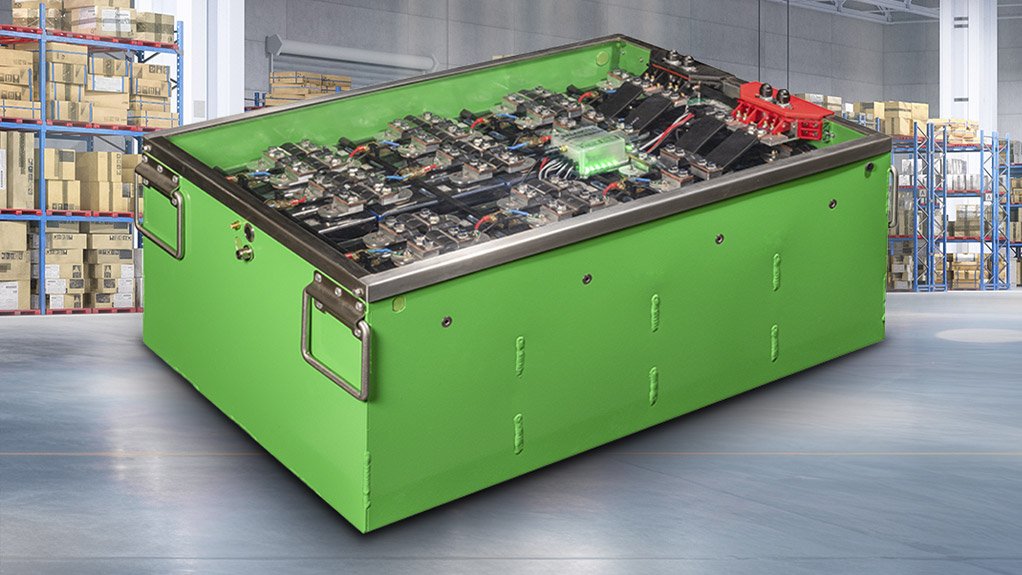

When a standard lithium battery was not sufficient to power the forklifts for long shifts at a seasonal agricultural operation in the Eastern Cape, it approached CFAO Equipment’s Industrial Power division for a bespoke solution that would suit its intensive requirements.

Duan Tredoux, National Operations Manager of Industrial Power, a division of CFAO Equipment, says the customer runs its forklifts intensively during harvesting season, with minimal breaks for opportunity charging. “During peak season, shifts are typically longer, requiring greater battery capacity to power through each one. The customer was looking for a longer-lasting solution that didn’t include the purchase of an additional battery.”

The Industrial Power team, in conjunction with CFAO Equipment’s Toyota Material Handling division, rose to the challenge, creating a modified lithium battery solution specifically designed to meet its customer’s specifications.

The solution is currently being tested by the customer, but early indications suggest the operation is enjoying longer runtimes, achieving close to 11-hour runtimes compared to six hours before having to charge again.

“The positive outcome for our customer is greater productivity at a reduced cost. Not only is there no need to invest in a second battery, with its associated equipment and storage costs, but not having to charge the battery during shifts means the time saving is significant,” notes Tredoux.

He adds that reliable battery solutions are critical for a host of industries. “When batteries or chargers do not supply quality power to industrial equipment, operations are directly impacted. In high-demand environments such as agriculture, manufacturing, construction, warehousing and logistics, consistent access to power ensures that equipment operates smoothly, minimising downtime and maximising productivity.”

High-quality batteries with longer life cycles and chargers with fast, consistent recharging capabilities help maintain seamless operations, preventing the productivity losses that come with unscheduled maintenance or replacement.

Too often, operations opt for chargers that cost less. This, says Tredoux, is counterproductive. “Although high-quality systems may involve higher upfront costs, they offer longer service lives, better energy efficiency and do not need to be replaced as often.

“Additionally, energy-efficient chargers lower electricity consumption and reduce operational expenses. Smart charging technology can also help manage power usage across multiple devices, optimising energy use, improving sustainability and further decreasing costs,” he adds.

Smart chargers are also designed to prevent overcharging and overheating, ensuring that batteries are maintained within safe parameters. This reduces the risk of accidents and enhances the overall safety of the workplace.

Industrial Power works closely with its customers to create long-term solutions for power efficiency. “For example, if a customer decides to shift from internal combustion (IC) forklifts to electric forklifts, we investigate the existing power supply and infrastructure to ensure they are capable of handling the change in operations.”

When choosing a power provider to partner with, operations need to do their homework. “They need to ensure they partner with legitimate suppliers who provide customised solutions and who have been operating in the market for an extended period. Industrial Power has been in operation since 2009 and supported every industry type in the country,” concludes Tredoux.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation