Powerstart hydraulic starter overcomes overseas quality concern challenge

Non-electric engine starting solutions company Powerworks has secured significant orders for its Powerstart hydraulic starter motors from overseas markets this year, despite the challenges faced by South African manufacturers when exporting their goods, says MD Nick Ruberg.

“Our export challenges are mainly driven by the reluctance of overseas customers to recognise the quality of South African products.”

Powerworks produces the only pre-engaged starter motor with the ATEX mark, indicating European certification given to equipment tested and approved as intrinsically safe. The company is also the only South African manufacturer to offer CE-marked hydraulic piston accumulators, says Ruberg.

“The country’s bad press regarding civil unrest also makes many customers nervous,” he adds.

Nonetheless, Powerworks secured orders from companies in Germany and the Far East, and from construction and mining equipment manufacturer Caterpillar in the US, and regularly exports to Europe, Australia and China.

The mining industry is the main driver of demand for these hydraulic starters in South Africa, which were designed for the African mining market and to deliver a higher duty cycle than competitor products, states Ruberg.

The product was developed owing to a need for non-electric starting, particularly in the local underground coal mining industry.

“Given South Africa’s dependence on coal-fired power stations for its electricity generation, local demand is good. We supply to integrated energy and chemicals company Sasol, mining major Anglo American’s former coal subsidiary [now Thungela], coal miner Seriti Coal and many smaller coal mines,” highlights Ruberg.

Overseas, the product has been applied in the energy generation, and oil and gas sectors, and anywhere there is a need to start an engine without a spark.

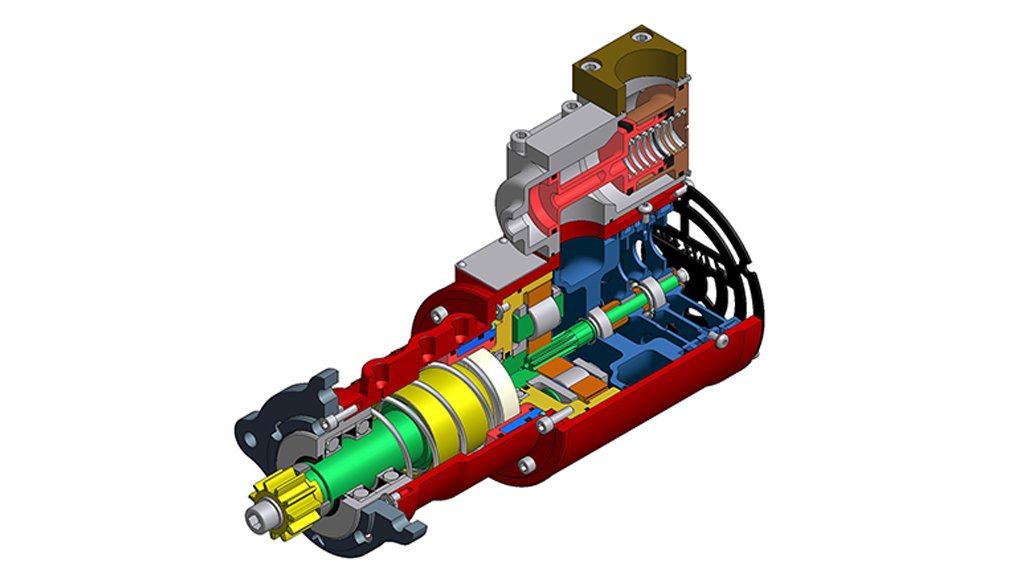

Powerstart hydraulic starters require no electricity and are, therefore, non-sparking, making them ideal for flameproof applications.

The product offers more power and torque a kilogram and faster cranking than electric starters, while being far lighter, elaborates Ruberg.

Totally sealed, these hydraulic starters are immune to contaminants such as coal dust, corrosive salt spray or any other harsh environmental conditions. All moving parts are submerged in oil.

Time to total recharge of the system is reduced to minutes, owing to an accumulator, compared with the hours needed to fully recharge the batteries of an electric starter. The absence of batteries also eliminates their maintenance and theft.

Further, hydraulic starting systems can be recharged manually using an optional hand pump, offering nearly indefinite energy storage.

The Powerstart range is also unaffected by temperature extremes, as long as the correct viscosity oil is used.

After its introduction in the early 1990s, Powerworks started manufacturing Powerstart hydraulic starter motors in-house in 1998.

It took Powerworks several years to develop the system following substantial design work, many field trials and working closely with end-user engine manufacturers.

“Finding customers interested in running field trials was the biggest challenge during development. However, this was overcome by offering our product free of charge and undertaking a significant amount of in-house testing, which necessitated the design and building of test benches,” explains Ruberg.

The Powerstart system has undergone many upgrades since its launch and is constantly evolving, says Ruberg.

“We have changed many materials, introducing specialised steel alloys and various other materials to combat corrosion and wear, as well as improved our manufacturing processes.”

The company’s latest Powerstart design, the pre-engaged starter, was introduced in 2010 after a three-year development cycle.

Manufactured at Powerworks’ factory in Midrand, Gauteng, Powerstart starters comprise about 90% local content. The remaining 10% entails imported components such as bearings and seals.

Using turning, milling, grinding and gear cutting, the company manufactures about 800 units a month, consisting of three sizes and six starter displacements. Engines as small as single cylinder water pumps and as large as 16 cylinder, 80 l earth-moving machinery power plants can be started using the Powerstart system.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation