Pump system showcased at expo

NO WASH-OUT The high pressure wash-down system designed by Sundyne was on show at this years International Production & Processing Expo held at the Georgia World Congress Center, in Atlanta US

International pumps and compressors designer and manufacturer Sundyne showcased its SundWASH high pressure wash-down systems for food and beverage applications at the International Production & Processing Expo held at the Georgia World Congress Center, in Atlanta, from January 25 to 27.

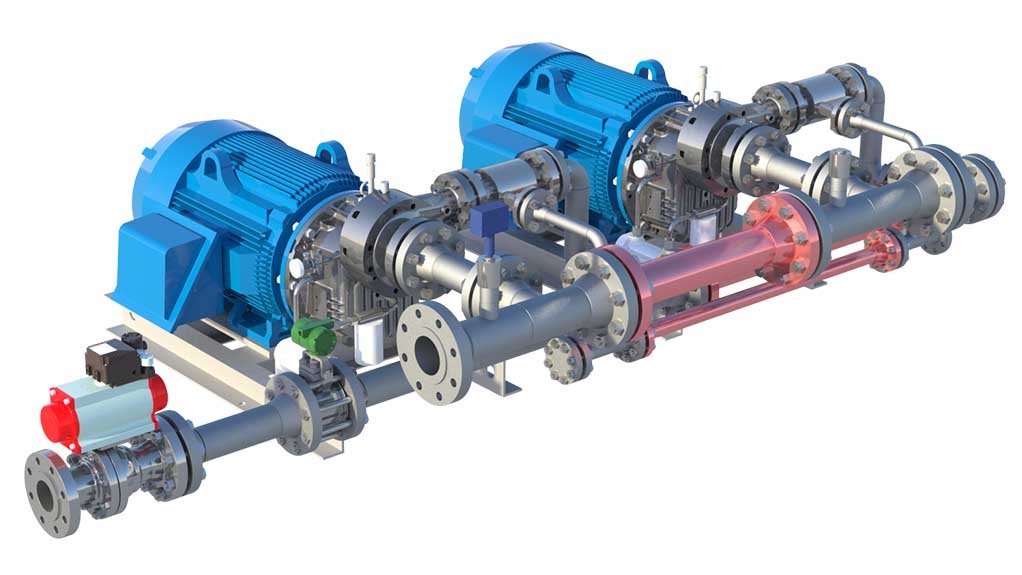

SundWASH high-pressure wash-down packages are complete pre-engineered systems that include all of the pressure, temperature and flow devices needed to deliver an optimised volume of water on demand.

SundWASH is used for cleaning and sanitation, odour control, dust suppression, deboning, scale removal and other applications required by facilities that process chicken, beef, pork, seafood, beer and wine.

Operating wash-down systems at high pressures provides superior cleaning results in less time, using less water, and in some cases, saving more than 380 000 ℓ/d.

These savings deliver a return on investment on SundWASH systems that can be quantified in just the first year of operation.

Water demand at food and beverage plants can change drastically during an eight-hour shift.

Single pumps struggle to scale as needed – but SundWASH parallel pump systems can boost pressure as needed, enabling operators to get the job done with less water and fewer chemicals, which further increases savings.

The SundWASH modular layout makes it easy to add wash-down packages in parallel to accommodate plant growth.

A “smart control” system regulates and maintains pump hydraulic performance, regardless of changing user demands.

“The Smart-Bypass programmable logic controller ensures that minimal hydraulic resources are used to deliver the right amount of power at extremely high pressures while maximising power savings,” says Sundyne product line manager Matt Moy.

He adds that SundWASH systems feature a small footprint that fits into almost any central utility room.

The Sunflo pumps powering these systems use a cartridge assembly that can be easily swapped out in place, in a matter of minutes, without having to disconnect the pump from pipe connections.

No additional alignments are necessary, which renders most repair times to less than 60 minutes.

SundWASH systems feature field-proven high-pressure impeller technology that is optimised to deliver high head.

Each member of the Sunflo pump family is optimised to provide a range of flow rates from about 15 ℓ/m to 2 080 ℓ/m, and head from 30.5 m to about 1 580 m.

Recent enhancements to Sunflo pumps include: new seal housings; a new labyrinth gearbox seal; splined impellers; new sleeves and O-rings; and improved bearings that increase performance and help the pumps resist upset conditions.

Each of these enhancements helps to ensure that high-pressure water is always available with continuous, stable flow.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation